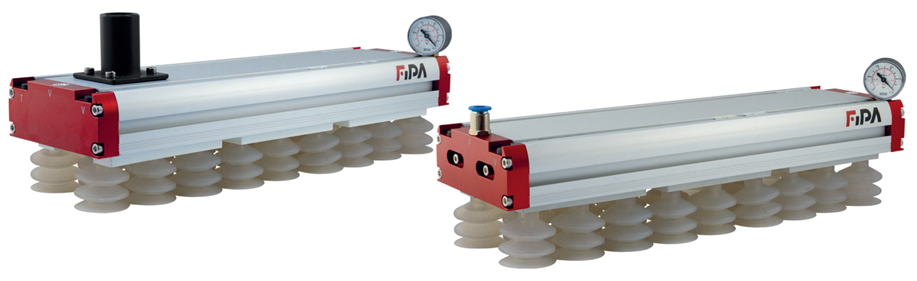

Area gripper with sealing foam

- For automated handling of individual products or product layers without changing grippers

- Low noise emissions for a pleasant working environment

- With built-in ejectors or with connection to a central vacuum supply

- With check valves or flow reduction

- The sealing foam can be replaced quickly, non-destructively and without residues

- Area grippers with check valves are suitable for swivel/tilt movements up to less than 90°

- Equipped with vacuum gauge 91.005 as standard

- Other sealing foams (height, shape) on request

Area gripper FSG-V with internal valves

.png)

Product features

- For automated handling of individual products or product layers without changing grippers

- Low noise emissions for a pleasant working enviroment

- With built-in catridgr ejectors

- With integrated valves to control the suction (NO) and blow-off (NC) functions

- With check valves or flow resistors

- The sealing foam can be replaced quickly, non-destructively and without leaving residues

| Item no. |

Value type

|

Lenght [mm] |

Number of suction cells

|

Working pressure

[bar (psi)]

|

Air consumption at 6 bar (87 psi)

[Nl/min]

|

Suction power at 6 bar (87psi)

[N]

|

Suction force at nominal power

[N]

|

Vacuum level

[mbar (inHg)]

|

Power supply

[V]

|

Current consumption at 24 VDC max [mA] |

Electric connection |

Weight

[kg]

|

| FSG.V.VG130.434.5F20C2 |

Check valve

|

434 |

83 |

4 - 6 (58 - 87) |

200 | 700 | 688 | -500 (-16.2) | 24 | 46 | 1x Plug M8x1; 4-pin | 3.8 |

| FSG.V.VG130.572.5F20C3 |

Check valve

|

572 |

113 |

4 - 6 (58 - 87) |

300 | 1050 | 909 | -500 (-16.2) | 24 | 46 | 1x Plug M8x1; 4-pin | 4.3 |

| FSG.V.VG130.711.5F20C4 |

Check valve

|

711 | 143 |

4 - 6 (58 - 87) |

400 | 1400 | 1150 | -500 (-16.2) | 24 | 46 | 1x Plug M8x1; 4-pin | 5 |

| FSG.V.VG130.849.5F20C4 |

Check valve

|

849 | 173 |

4 - 6 (58 - 87) |

400 | 1400 | 1391 | -500 (-16.2) | 24 | 46 | 1x Plug M8x1; 4-pin | 5.7 |

| FSG.V.VG130.988.5F20C5 |

Check valve

|

988 | 203 |

4 - 6 (58 - 87) |

500 | 1750 | 1633 | -500 (-16.2) | 24 | 92 | 2x Plug M8x1; 4-pin | 6.1 |

| FSG.V.VG130.1126.5F20C6 |

Check valve

|

1126 | 233 |

4 - 6 (58 - 87) |

600 | 2100 | 1874 | -500 (-16.2) | 24 | 92 | 2x Plug M8x1; 4-pin | 7.5 |

| FSG.V.VG130.1265.5F20C6 |

Check valve

|

1265 | 263 |

4 - 6 (58 - 87) |

600 | 2100 | 2115 | -500 (-16.2) | 24 | 92 | 2x Plug M8x1; 4-pin | 7.9 |

| FSG.V.PG130.434.5F20C2 |

Flow reduction

|

434 | 83 |

4 - 6 (58 - 87) |

200 | 700 | 688 | -500 (-16.2) | 24 | 46 | 1x Plug M8x1; 4-pin | 3.8 |

| FSG.V.PG130.572.5F20C3 |

Flow reduction

|

572 | 113 |

4 - 6 (58 - 87) |

300 | 1050 | 909 | -500 (-16.2) | 24 | 46 | 1x Plug M8x1; 4-pin | 4.3 |

| FSG.V.PG130.711.5F20C4 |

Flow reduction

|

711 | 143 |

4 - 6 (58 - 87) |

400 | 1400 | 1150 | -500 (-16.2) | 24 | 46 | 1x Plug M8x1; 4-pin | 5 |

| FSG.V.PG130.849.5F20C4 |

Flow reduction

|

849 | 173 |

4 - 6 (58 - 87) |

400 | 1400 | 1391 | -500 (-16.2) | 24 | 46 | 1x Plug M8x1; 4-pin | 5.7 |

| FSG.V.PG130.988.5F20C5 |

Flow reduction

|

988 | 203 |

4 - 6 (58 - 87) |

500 | 1750 | 1633 | -500 (-16.2) | 24 | 92 | 2x Plug M8x1; 4-pin | 6.1 |

| FSG.V.PG130.1126.5F20C6 |

Flow reduction

|

1126 | 233 |

4 - 6 (58 - 87) |

600 | 2100 | 1874 | -500 (-16.2) | 24 | 92 | 2x Plug M8x1; 4-pin | 7.5 |

| FSG.V.VG130.1265.5F20C6 |

Flow reduction

|

1265 | 263 |

4 - 6 (58 - 87) |

600 | 2100 | 2115 | -500 (-16.2) | 24 | 92 | 2x Plug M8x1; 4-pin | 7.9 |

.png)

.png)

| Item no. | A [mm] |

| FSG.V.VG130.434.5F20C2 | 434 |

| FSG.V.VG130.572.5F20C3 | 572 |

| FSG.V.VG130.711.5F20C4 | 711 |

| FSG.V.VG130.849.5F20C4 | 849 |

| FSG.V.VG130.988.5F20C5 | 988 |

| FSG.V.VG130.1126.5F20C6 | 1,126 |

| FSG.V.VG130.1265.5F20C6 | 1,265 |

| FSG.V.PG130.434.5F20C2 | 434 |

| FSG.V.PG130.572.5F20C3 | 572 |

| FSG.V.PG130.711.5F20C4 | 711 |

| FSG.V.VG130.849.5F20C4 | 849 |

| FSG.V.PG130.988.5F20C5 | 988 |

| FSG.V.PG130.1126.5F20C6 | 1,126 |

| FSG.V.VG130.1265.5F20C6 | 1,265 |

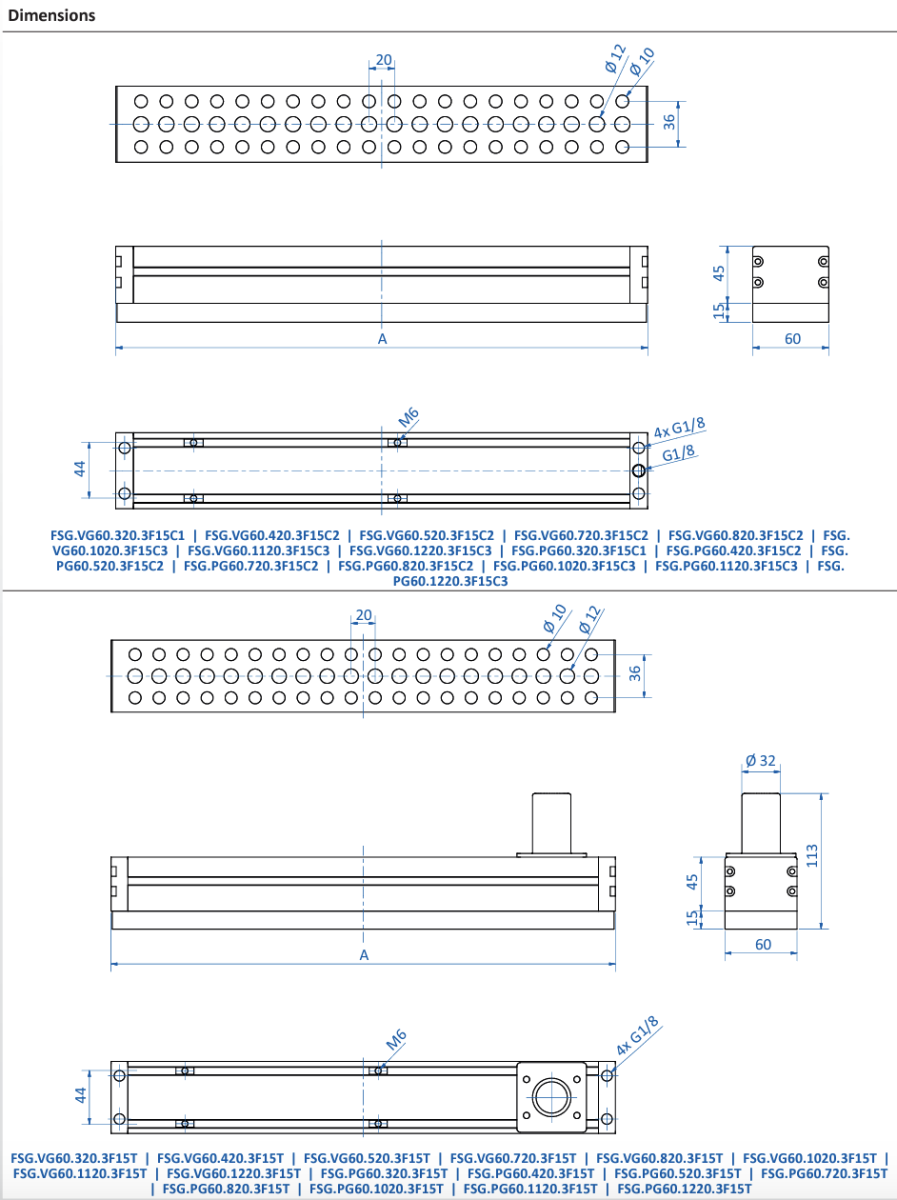

Area gripper FSG 60 with sealing foam

- For automated handling of individual products or product layers without changing grippers.

- Especially for use in confined spaces

- Low noise emissions for a pleasant working environment

- With built-in ejectors or with connection to central vacuum supply

- With check valves or flow resistors

- The sealing foam can be replaced quickly, non-destructively and without leaving residues

- Suitable for handling inherently stable products such as wood or glass

| Item no. | Valve type | Vacuum generation | Number of suction cells | Working pressure [bar (psi)] | Air consumption at 6 bar (87 psi) [Nl/min] |

Suction power at 6 bar (87 psi) [Nl/min]

|

Nominal flow rate [Nl/min] |

Suction force at nominal power [N]

|

Vacuum level [mbar (inHg)]

|

Weight [kg]

|

Dimensions A [mm] |

| FSG.VG60.320.3F15C1 | Check valve | with integrated ejectors | 45 | 4 - 6 (58 - 87) | 100 | 350 | -- | 243 | -600 (-17.7) | 1.4 | 320 |

| FSG.VG60.420.3F15C2 | Check valve | with integrated ejectors | 60 | 4 - 6 (58 - 87) | 200 | 700 | -- | 324 | -600 (-17.7) | 1.6 | 420 |

| FSG.VG60.520.3F15C2 | Check valve | with integrated ejectors | 75 | 4 - 6 (58 - 87) | 200 | 700 | -- | 405 | -600 (-17.7) | 1.8 | 520 |

| FSG.VG60.720.3F15C2 | Check valve | with integrated ejectors | 105 | 4 - 6 (58 - 87) | 200 | 700 | -- | 567 | -600 (-17.7) | 2.3 | 720 |

| FSG.VG60.820.3F15C2 | Check valve | with integrated ejectors | 120 | 4 - 6 (58 - 87) | 200 | 700 | -- | 648 | -600 (-17.7) | 2.5 | 820 |

| FSG.VG60.1020.3F15C3 | Check valve | with integrated ejectors | 150 | 4 - 6 (58 - 87) | 300 | 1,050 | -- | 811 | -600 (-17.7) | 3 | 1,020 |

| FSG.VG60.1120.3F15C3 | Check valve | with integrated ejectors | 165 | 4 - 6 (58 - 87) | 300 | 1,050 | -- | 892 | -600 (-17.7) | 3.2 | 1,020 |

| FSG.VG60.1220.3F15C3 | Check valve | with integrated ejectors | 180 | 4 - 6 (58 - 87) | 300 | 1,050 | -- | 973 | -600 (-17.7) | 3.4 | 1,020 |

| FSG.PG60.320.3F15C1 | Flow reduction | with integrated ejectors | 45 | 4 - 6 (58 - 87) | 100 | 350 | -- | 243 | -600 (-17.7) | 1.4 | 320 |

| FSG.PG60.420.3F15C2 | Flow reduction | with integrated ejectors | 60 | 4 - 6 (58 - 87) | 200 | 700 | -- | 324 | -600 (-17.7) | 1.6 | 420 |

| FSG.PG60.520.3F15C2 | Flow reduction | with integrated ejectors | 75 | 4 - 6 (58 - 87) | 200 | 700 | -- | 405 | -600 (-17.7) | 1.8 | 520 |

| FSG.PG60.720.3F15C2 | Flow reduction | with integrated ejectors | 105 | 4 - 6 (58 - 87) | 200 | 700 | -- | 567 | -600 (-17.7) | 2.3 | 720 |

| FSG.PG60.820.3F15C2 | Flow reduction | with integrated ejectors | 120 | 4 - 6 (58 - 87) | 200 | 700 | -- | 648 | -600 (-17.7) | 1.5 | 820 |

| FSG.PG60.1020.3F15C3 | Flow reduction | with integrated ejectors | 150 | 4 - 6 (58 - 87) | 300 | 1,050 | -- | 811 | -600 (-17.7) | 3 | 1,020 |

| FSG.PG60.1120.3F15C3 | Flow reduction | with integrated ejectors | 165 | 4 - 6 (58 - 87) | 300 | 1,050 | -- | 892 | -600 (-17.7) | 3.2 | 1,020 |

| Item no. | Valve type | Vacuum generation | Number of suction cells | Working pressure [bar (psi)] | Air consumption at 6 bar (87 psi) [Nl/min] |

Suction power at 6 bar (87 psi) [Nl/min]

|

Nominal flow rate [Nl/min] |

Suction force at nominal power [N]

|

Vacuum level [mbar (inHg)]

|

Weight [kg]

|

Dimensions A [mm] |

| FSG.PG60.1220.3F15C3 | Flow reduction | with integrated ejectors | 180 | 4 - 6 (58 - 87) | 300 | 1,050 | -- | 973 | -600 (-17.7) | 3.4 | 1,220 |

| FSG.VG60.320.3F15T | Check valve | central vacuum supply | 45 | -- | -- | -- | 150 | 162 | -400 (-11.8) | 1 | 320 |

| FSG.VG60.420.3F15T | Check valve | central vacuum supply | 60 | -- | -- | -- | 300 | 216 | -400 (-11.8) | 1.2 | 420 |

| FSG.VG60.520.3F15T | Check valve | central vacuum supply | 75 | -- | -- | -- | 290 | 270 | -400 (-11.8) | 1.4 | 520 |

| FSG.VG60.720.3F15T | Check valve | central vacuum supply | 105 | -- | -- | -- | 510 | 378 | -400 (-11.8) | 1.9 | 720 |

| FSG.VG60.820.3F15T | Check valve | central vacuum supply | 120 | -- | -- | -- | 560 | 432 | -400 (-11.8) | 2.1 | 820 |

| FSG.VG60.1020.3F15T | Check valve | central vacuum supply | 150 | -- | -- | -- | 750 | 540 | -400 (-11.8) | 2.6 | 1,020 |

| FSG.VG60.1120.3F15T | Check valve | central vacuum supply | 165 | -- | -- | -- | 900 | 594 | -400 (-11.8) | 2.8 | 1,020 |

| FSG.VG60.1220.3F15T | Check valve | central vacuum supply | 180 | -- | -- | -- | 900 | 648 | -400 (-11.8) | 3.1 | 1,020 |

| FSG.PG60.320.3F15T | Flow reduction | central vacuum supply | 45 | -- | -- | -- | 150 | 162 | -400 (-11.8) | 1 | 320 |

| FSG.PG60.420.3F15T | Flow reduction | central vacuum supply | 60 | -- | -- | -- | 300 | 216 | -400 (-11.8) | 1.2 | 420 |

| FSG.PG60.520.3F15T | Flow reduction | central vacuum supply | 75 | -- | -- | -- | 390 | 270 | -400 (-11.8) | 1.4 | 520 |

| FSG.PG60.720.3F15T | Flow reduction | central vacuum supply | 105 | -- | -- | -- | 510 | 378 | -400 (-11.8) | 1.9 | 720 |

| FSG.PG60.820.3F15T | Flow reduction | central vacuum supply | 120 | -- | -- | -- | 560 | 432 | -400 (-11.8) | 2.1 | 820 |

| FSG.PG60.1020.3F15T | Flow reduction | central vacuum supply | 150 | -- | -- | -- | 750 | 540 | -400 (-11.8) | 2.6 | 1,020 |

| FSG.PG60.1120.3F15T | Flow reduction | central vacuum supply | 165 | -- | -- | -- | 900 | 594 | -400 (-11.8) | 2.8 | 1,020 |

| FSG.PG60.1220.3F15T | Flow reduction | central vacuum supply | 180 | -- | -- | -- | 900 | 648 | -400 (-11.8) | 3.1 | 1,220 |

Optional accessories and spare parts:

Optional accessories:

- Electronic vacuum switch with display GS02.001

- Electronic vacuum switch GS02.003

- Electronic vacuum and pressure switch 20.026

Spare parts:

- Cartridge ejector for area gripper FSG.ACC130.0003

Max. Suction force as a function of operating pressure

.png)

Max. Vacuum level above operating pressure

.png)

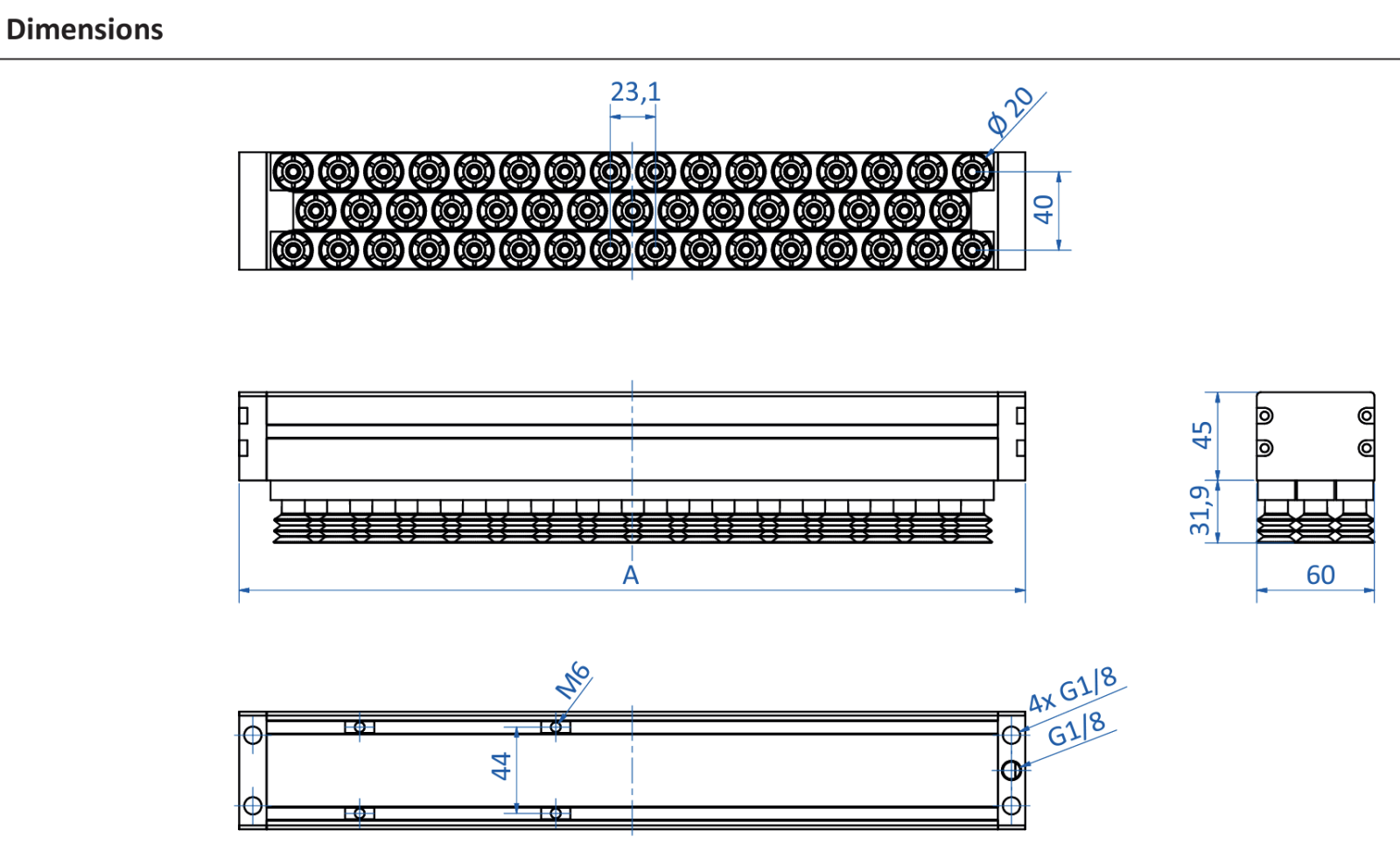

Area gripper FSG 60 with plug-in cups

.png)

- For automated handling of individual products or product layers without changing grippers.

- Especially for use in confined spaces

- Low noise emissions for a pleasant working environment

- With built-in ejectors or with connection to central vacuum supply

- With check valves or flow resistors

- The sealing foam can be replaced quickly, non-destructively and without leaving residues

- Suitable for handling inherently stable products such as wood or glass

| Item no. | Valve type | Vacuum generation | Number of vacuum cups | Working pressure [bar (psi)] | Air consumption at 6 bar (87 psi) [Nl/min] |

Suction power at 6 bar (87 psi) [Nl/ min]

|

Suction force at nominal power [N]

|

Vacuum level [mbar (inHg)]

|

Weight [kg]

|

Dimensions A [mm] |

| FSG.VG60.285.3C20C1 | Check valve | with integrated ejectors | 32 | 4 - 6 (58 - 87) | 100 | 350 | 386 | -600 (-17.7) | 1 | 285 |

| FSG.VG60.401.3C20C2 | Check valve | with integrated ejectors | 47 | 4 - 6 (58 - 87) | 200 | 700 | 566 | -600 (-17.7) | 1.6 | 401 |

| FSG.VG60.516.3C20C2 | Check valve | with integrated ejectors | 62 | 4 - 6 (58 - 87) | 200 | 700 | 747 | -600 (-17.7) | 1.9 | 516 |

| FSG.VG60.701.3C20C2 | Check valve | with integrated ejectors | 86 | 4 - 6 (58 - 87) | 200 | 700 | 1,037 | -600 (-17.7) | 2.4 | 701 |

| FSG.VG60.816.3C20C2 | Check valve | with integrated ejectors | 101 | 4 - 6 (58 - 87) | 200 | 700 | 1,218 | -600 (-17.7) | 2.7 | 816 |

| FSG.VG60.1001.3C20C3 | Check valve | with integrated ejectors | 125 | 4 - 6 (58 - 87) | 300 | 1,050 | 1,507 | -600 (-17.7) | 3.2 | 1,001 |

| FSG.VG60.1117.3C20C3 | Check valve | with integrated ejectors | 140 | 4 - 6 (58 - 87) | 300 | 1,050 | 1,688 | -600 (-17.7) | 3.5 | 1,117 |

| FSG.VG60.1209.3C20C3 | Check valve | with integrated ejectors | 152 | 4 - 6 (58 - 87) | 300 | 1,050 | 1,833 | -600 (-17.7) | 3.7 | 1,209 |

| FSG.PG60.285.3C20C1 | Flow reduction | with integrated ejectors | 32 | 4 - 6 (58 - 87) | 100 | 350 | 286 | -600 (-17.7) | 1 | 285 |

| FSG.PG60.401.3C20C2 | Flow reduction | with integrated ejectors | 47 | 4 - 6 (58 - 87) | 200 | 700 | 566 | -600 (-17.7) | 1.6 | 401 |

| FSG.PG60.516.3C20C2 | Flow reduction | with integrated ejectors | 62 | 4 - 6 (58 - 87) | 200 | 700 | 747 | -600 (-17.7) | 1.9 | 516 |

| FSG.PG60.701.3C20C2 | Flow reduction | with integrated ejectors | 86 | 4 - 6 (58 - 87) | 200 | 700 | 1,037 | -600 (-17.7) | 2.4 | 701 |

| FSG.PG60.816.3C20C2 | Flow reduction | with integrated ejectors | 101 | 4 - 6 (58 - 87) | 200 | 700 | 1,218 | -600 (-17.7) | 2.7 | 816 |

| FSG.PG60.1001.3C20C3 | Flow reduction | with integrated ejectors | 125 | 4 - 6 (58 - 87) | 300 | 1,050 | 1,507 | -600 (-17.7) | 3.2 | 1,001 |

| FSG.PG60.1117.3C20C3 | Flow reduction | with integrated ejectors | 140 | 4 - 6 (58 - 87) | 300 | 1,050 | 1,688 | -600 (-17.7) | 3.5 | 1,117 |

| FSG.PG60.1209.3C20C3 | Flow reduction | with integrated ejectors | 152 | 4 - 6 (58 - 87) | 300 | 1,050 | 1,833 | -600 (-17.7) | 3.7 | 1.209 |

Optional accessories and spare parts:

Optional accessories:

- Electronic vacuum switch with display GS02.001

- Electronic vacuum switch GS02.003

- Electronic vacuum and pressure switch 20.026

Spare parts:

- Cartridge ejector for area gripper FSG.ACC130.0003

Area gripper with plug-in vacuum cups diameter 20 mm

- For automated handling of individual products or product layers without changing grippers

- Low noise emissions for a pleasant working environment

- With built-in ejectors or with connection to a central vacuum supply

- With check valves or flow reduction

- The sealing foam can be replaced quickly, non-destructively and without residues

- Area grippers with check valves are suitable for swivel/tilt movements up to less than 90°

- Equipped with vacuum gauge 91.005 as standard

Area gripper with plug-in vacuum cups diameter 40 mm

- For automated handling of individual products or product layers without changing grippers

- Low noise emissions for a pleasant working environment

- With built-in ejectors or with connection to a central vacuum supply

- With check valves or flow reduction

- The sealing foam can be replaced quickly, non-destructively and without residues

- Area grippers with check valves are suitable for swivel/tilt movements up to less than 90°

- Equipped with vacuum gauge 91.005 as standard

- Other sealing foams (height, shape) on request

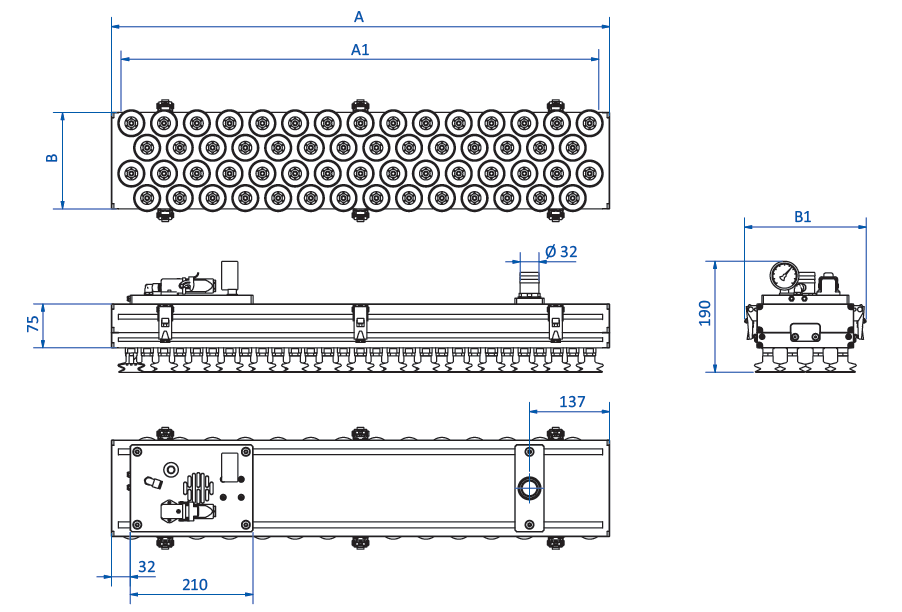

Area gripper SBX-F with vacuum cups diameter 43 mm

> The area gripper for the highest demands and most difficult applications

> For automated handling of individual products or product layers without changing grippers

> Maximum gripping safety with the highest vacuum level and minimum coverage at the same time

> This means that both the smallest and the largest components can be gripped safely with the same vacuum level without changing the gripper

> Highest availability due to replacement of critical modules within seconds

> Very short cycle times possible due to very fast suction of a workpiece

> Particularly energy-efficient due to fully closing valves without bypass or leaks

> Vacuum cups with Ø 43 mm made of NR as standard, various other vacuum cups can be supplied to customer needs

> Customer-specific lengths from 400 to 3,000 mm possible

> Customized grid arrangement of the vacuum cups possible

| Item no. | Total length [mm] | Width [mm] | Number of vacuum cups | Lifting force at -0.35 bar (-5.07 psi) [kg] | Lifting force at -0.6 bar (-8.7 psi) [kg] | Weight [kg] |

| SBX-F.130.436.3R56-VC43 | 460 | 130 | 23 | 31 | 53 | 6,6 |

| SBX-F.130.632.3R56-VC43 | 656 | 130 | 33 | 44 | 76 | 9,9 |

| SBX-F.130.828.3R56-VC43 | 852 | 130 | 44 | 60 | 102 | 12,2 |

| SBX-F.130.1248.3R56-VC43 | 1,274 | 130 | 66 | 89 | 153 | 18,8 |

| SBX-F.165.436.4R56-VC43 | 460 | 165 | 30 | 40 | 69 | 8,8 |

| SBX-F.165.632.4R56-VC43 | 656 | 165 | 44 | 59 | 102 | 11,2 |

| SBX-F.165.828.4R56-VC43 | 852 | 165 | 58 | 81 | 139 | 14,6 |

| SBX-F.165.1248.4R56-VC43 | 1,274 | 165 | 88 | 119 | 204 | 20,4 |

| Item no. | A [mm] | A1 [mm] | B [mm] | B1 [mm] |

| SBX-F.130.436.3R56-VC43 | 460 | 436 | 130 | 178 |

| SBX-F.130.632.3R56-VC43 | 656 | 632 | 130 | 178 |

| SBX-F.130.828.3R56-VC43 | 852 | 828 | 130 | 178 |

| SBX-F.130.1248.3R56-VC43 | 1,274 | 1,25 | 130 | 178 |

| SBX-F.165.436.4R56-VC43 | 460 | 436 | 165 | 208 |

| SBX-F.165.632.4R56-VC43 | 656 | 632 | 165 | 208 |

| SBX-F.165.828.4R56-VC43 | 852 | 828 | 165 | 208 |

| SBX-F.165.1248.4R56-VC43 | 1,274 | 1,25 | 165 | 208 |

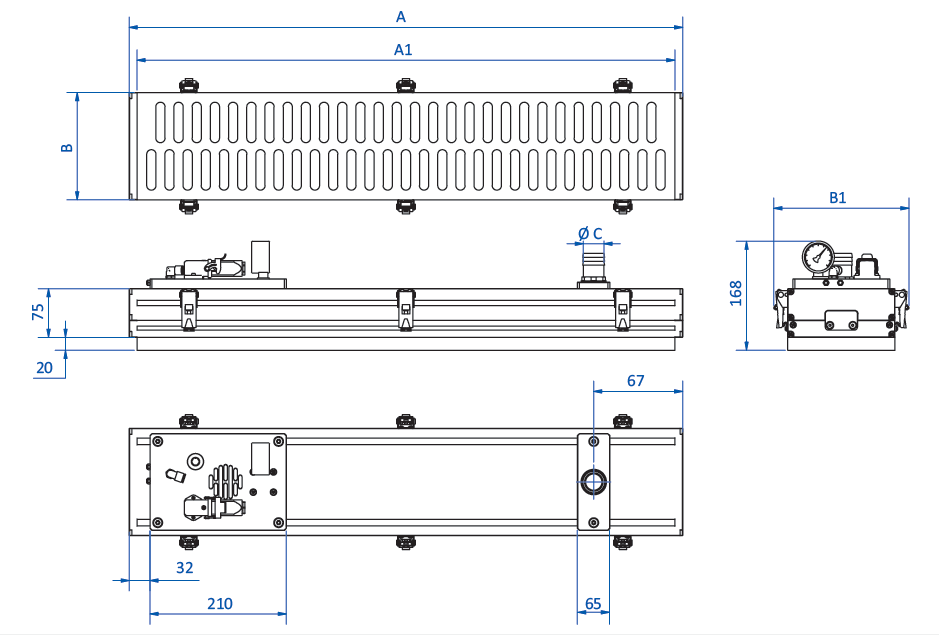

Area gripper SBX-F with sealing foam

> The area gripper for the highest demands and most difficult applications

> For automated handling of individual products or product layers without changing grippers

> Maximum gripping safety with the highest vacuum level and minimum coverage at the same time

> This means that both the smallest and the largest components can be gripped safely with the same vacuum level without changing the gripper

> Highest availability due to replacement of critical modules within seconds

> Very short cycle times possible due to very fast suction of a workpiece

> Particularly energy-efficient due to fully closing valves without bypass or leaks

> Foam made of EPDM 20 mm high (standard), various other foams can be customized

> Customer-specific lengths from 400 to 3,000 mm possible

> Customer-specific grid division of the suction cells possible

| Item no. | Total length [mm] | Width [mm] | Number of suction cells | Lifting force at -0.35 bar (-5.07 psi) [kg] | Lifting force at -0.6 bar (-8.7 psi) [kg] | Weight [kg] |

| SBX-F.130.436.2R28-F20 | 460 | 130 | 29 | 60 | 101 | 6 |

| SBX-F.130.632.2R28-F20 | 656 | 130 | 43 | 90 | 150 | 9 |

| SBX-F.130.828.2R28-F20 | 852 | 130 | 57 | 120 | 200 | 11 |

| SBX-F.130.1248.2R28-F20 | 1,274 | 130 | 87 | 182 | 304 | 17 |

| SBX-F.165.436.2R28-F20 | 460 | 165 | 29 | 84 | 145 | 8 |

| SBX-F.165.632.2R28-F20 | 656 | 165 | 43 | 124 | 215 | 10 |

| SBX-F.165.828.2R28-F20 | 852 | 165 | 57 | 165 | 285 | 13 |

| SBX-F.165.1248.2R28-F20 | 1,274 | 165 | 87 | 252 | 435 | 18 |

| Item no. | A [mm] | A1 [mm] | B [mm] | B1 [mm] | C [mm] |

| SBX-F.130.436.2R28-F20 | 460 | 436 | 130 | 178 | 32 |

| SBX-F.130.632.2R28-F20 | 656 | 632 | 130 | 178 | 32 |

| SBX-F.130.828.2R28-F20 | 852 | 828 | 130 | 178 | 32 |

| SBX-F.130.1248.2R28-F20 | 1,274 | 1,25 | 130 | 178 | 38 |

| SBX-F.165.436.2R28-F20 | 460 | 436 | 165 | 208 | 32 |

| SBX-F.165.632.2R28-F20 | 656 | 632 | 165 | 208 | 32 |

| SBX-F.165.828.2R28-F20 | 852 | 828 | 165 | 208 | 32 |

| SBX-F.165.1248.2R28-F20 | 1,274 | 1,25 | 165 | 208 | 38 |

SBP2 – Plug-In vacuum cups

Product features

- Bellows vacuum cups for direct installation in bores and housings

- Simple and tool-free exchange

- Dynamic use on cardboard and packaging

- Compatible with common vacuum gripping systems

- Optionally with built-in flow resistance to reduce leakage

Flow resistors available separately

- 270.730: SW08 = 0.8 mm; POM white

- 270.731: SW10 = 1.0 mm; POM blue

- 270.732: SW13 = 1.3 mm; POM black

- 270.733: SW15 = 1.5 mm; POM white

*.2 = SI (tr) Silicone transparent, Shore hardness 55°

*.8 = SI (w) Silicone white, Shore hardness 35°

Order example:

21.020.185.2 = Plug-In vacuum cup single, Shore hardness 55°

Slotnut 1x M8 for area gripper FSG

Replacement foam for area gripper FSG

Product features

- Material EPDM, resistant to weathering, ozone and most acids and alkalis. Not resistant to oils and greases.

- Good stand-up behaviour for short cycle times.

- Applied on strong self-adhesive film for quick and easy replacement of the foam on the area gripper

- The foam on the film comes off the area gripper without leaving residues

- As filter foam with plastic fabric with hole size 0.1 mm for applications in dusty and dirty environments – on request

- As valve foam for handling cans, jars, bottles, etc. – on request

Flange modul for area gripper FSG

.PNG)

.PNG)