Automated labelling machine ALM1000

Description

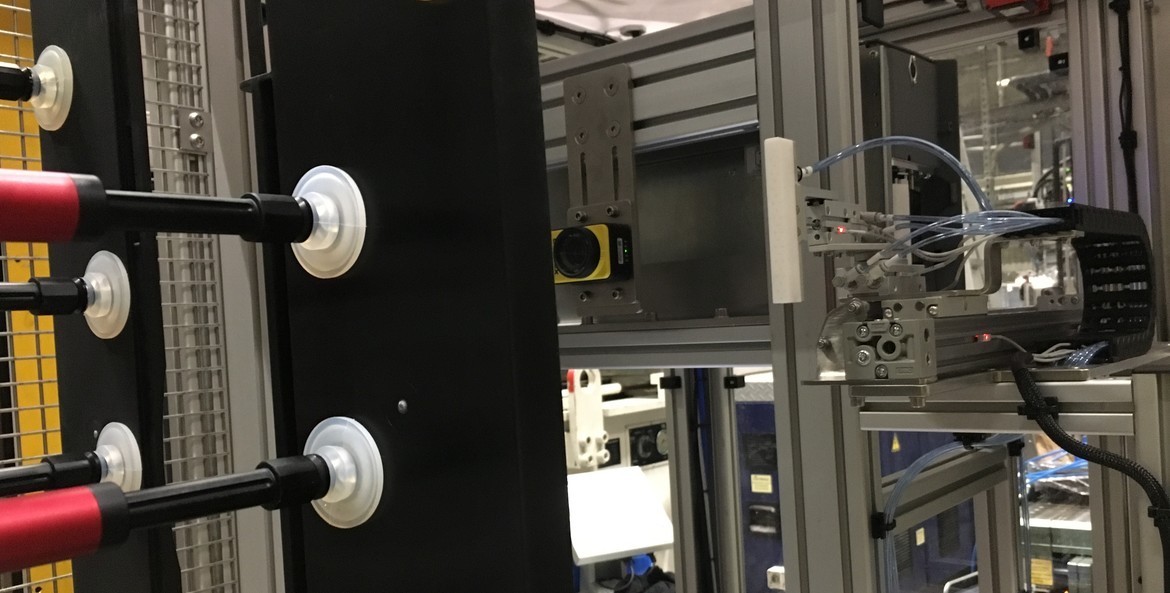

ALM 1000 labeling station is dedicated to work with parts received directly from the injection molding machine. The labeling head of the device is made in accordance with individual customer requirements regarding the material and dimensions of the label and the shape of the labeled part. The machine interface allows full control of the machine’s operation and the editing of data on the label. Vision control system (optional) guarantees full verification of the correctness of the printout and the place where the label is placed. The ALM 1000 labeling station is designed for cooperation with industrial robots of any type or manufacturer. The ALM 1000 machine is capable of handling single and multiple molds.

Functions

• Intuitive HMI panel menus for viewing statistics and modifying printed data

• Large service doors that provide convenient access to the most important components of the device

• Printing labels with different angular orientation

• Communication with robots of all types and manufacturers

• Cycle time for one label less than 3 seconds

Options

• Bar code verification

• QR code verification

• Verification of the position and orientation of the label

• Communication with additional devices / integration with ERP/MES

• Additional lighting for vision system

• Export of statistics to an external server

• Pressure drop indication

• Dedicated labeling head for parts with unusual shapes

• Modification of device’s dimensions

• Adjustments to the specific on-site requirements