CE marking for production cells

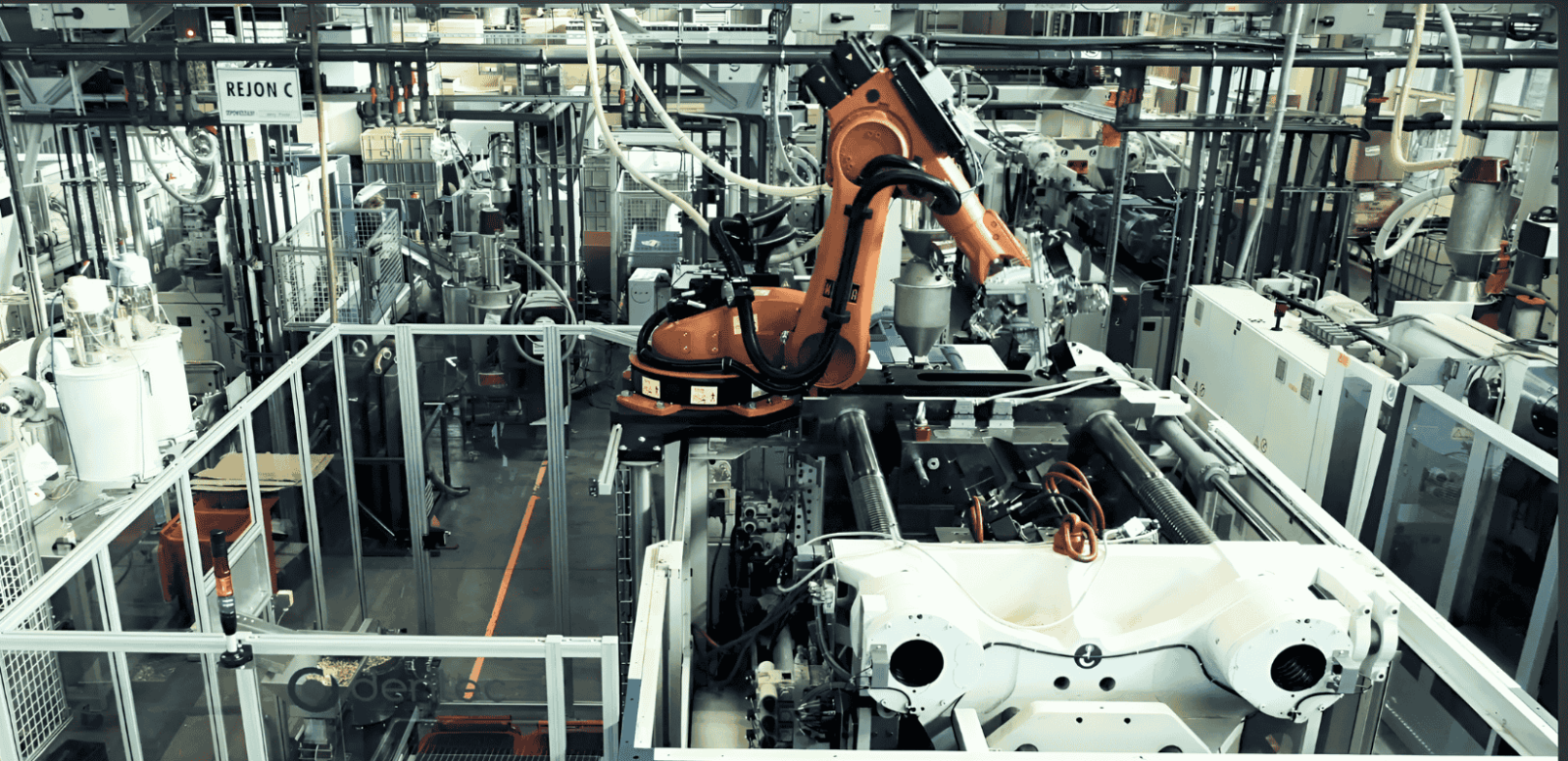

Do you have, or are you implementing, integrated injection moulding machines and robots (Cartesian or 6-axis), along with peripheral stations such as packaging, sprue and gate trimming, or insert feeders? Remember that after such integration you create a production cell which, as an assembly of machinery, requires a separate risk assessment and CE compliance process - regardless of whether the individual machines already have CE marking.

At Dentec we deliver end-to-end: safety audits, risk assessment, upgrades and improvements, and preparation of the documentation needed to safely put the workstation into operation.

Stages of CE marking for an assembly of machinery at your plant

Step 1: Safety audit and risk assessment

We start by checking your machine or production cell against safety requirements. We perform a safety audit and risk assessment, and then prepare a report that clearly shows:

- where non-conformities and hazards are,

- which elements require changes or upgrades,

- what actions are necessary to meet the Machinery Directive requirements.

.png)

Result: you get a clear action plan, priorities and recommendations that can be implemented step by step - without chaos or guesswork.

Step 2: Machine modifications and improvements

Based on the audit results, we implement the necessary changes in functional safety and mechanical safeguarding. Typical work includes:

- modifying and upgrading mechanical guards,

- reviewing and modernising control and safety systems,

- retrofitting safety devices (e.g. light curtains, safety switches, programmable safety relays/controllers).

Result: the production cell becomes genuinely safer, with solutions selected for your application and process.

Step 3: CE marking and Declaration of Conformity

After the changes are implemented, we close the topic both formally and technically. We support you in preparing the documentation and the commissioning process, including:

- CE marking of the production cell (assembly of machinery),

- formal confirmation of compliance with safety requirements,

- organising the documentation for the upgraded workstation.

Result: you have a workstation ready for safe operation, with organised documentation and clearly defined rules of use.

The Machinery Directive in practice: CE marking for robotised workstations

CE marking applies to the entire production cell, not just individual machines

This is a common mistake in plants: the injection moulding machine has CE marking from the manufacturer, the robot has CE marking, so "everything should be fine". In practice, after integration:

- a 6-axis or Cartesian robot is often treated as partly completed machinery,

- an injection moulding machine operating on its own may be a complete machine with the manufacturer's CE marking,

- an injection moulding machine + robot becomes an assembly of machinery that requires a new risk assessment and CE marking for the entire cell,

- if you add peripherals (packaging, vision inspection, sprue/gate trimming station, insert feeders and others), an additional risk assessment and CE update is usually required.

In short: CE marking of components does not automatically add up to CE marking of the complete workstation.

National Labour Inspectorate (PIP) inspections: risk of fines and production stoppages

Non-conformities in machinery safety are a real business risk. An inspection may reveal gaps in safeguarding and documentation, and the consequences may include:

- an order to remove non-conformities,

- stopping selected lines,

- significant fines and employer liability.

That is why a safety audit and CE compliance for the production cell is not "paperwork" - it is protection for production continuity.

Benefits of CE compliance for a production cell

- Employee safety - reduced accident risk and improved workstation ergonomics.

- Compliance with Machinery Directive requirements - structured risk assessment and implemented safeguards.

- Production continuity - lower risk of downtime due to non-conformities and inspections.

- Reduced risk of fines and administrative decisions - lower employer-side risk exposure.

Technical measures used in CE compliance for an assembly of machinery

Depending on the application and the risk assessment results, we implement, among others:

- light curtains and access safeguarding for hazardous zones,

- safety switches (e.g. on guards and doors),

- programmable safety relays/controllers and safety control components,

- control system upgrades in the scope of safety functions,

- retrofitting or rebuilding mechanical guards.