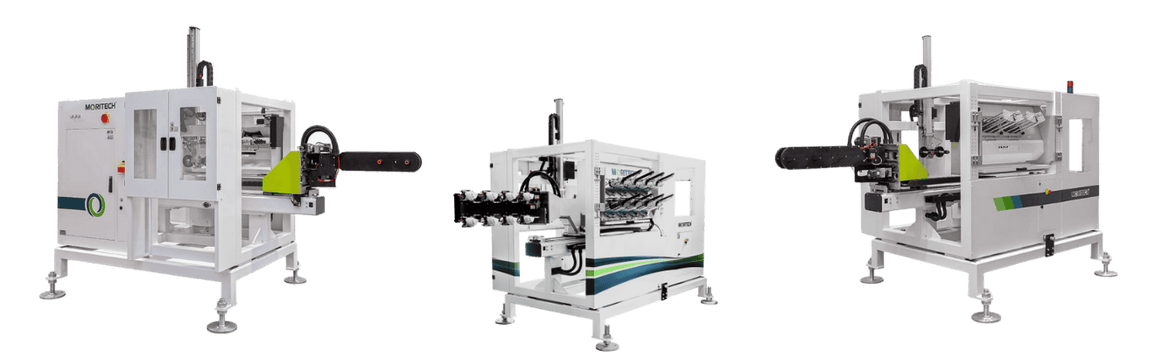

Moritech cartesian IML robots

Cartesian Side-Entry IML robots, with their robust mechanical chassis, provide fast cycle times and consistent production standards for IML food packaging operations.

Moritech Robot offers 2, 3 and 5 axis servo robots aiming plastic injection sector, which are controlled by user-friendly touch-screen HMI device. While robot utilization enable reduction of production defects to minimum levels, it allows a constant and planned daily production capacity regardless of the operator. Robots also prevent damage caused by physical contact of molds on products. Furthermore, robot employment ensures effective measures of work safety.

Achieving ultra-fast take-out cycles below one second and maintaining exceptional repeatability is made possible with powerful motors that perfectly balance moving masses. Designed to meet the high expectations of demanding customers, this robot series delivers advanced functions tailored to the plastics packaging sector, including minimized mold-open durations and customizable sorting and stacking programs for precise, efficient production.

Moritech redefines efficiency standards, offering cost-effective solutions precisely tailored to your requirements.

Easy operation

Control panel with touch-screen property enable easy operation via simple and intuitive interface.

Integrated visual inspection and boxing

The system integrates visual cameras for quality inspection and features a flexible programming structure for automated packaging, ensuring high precision and adaptability in production processes.

Efficient production

Bi-mutual motion construction in all axis, servo robotic systems providing energy efficiency with their lightweight design and rigid construction.

Stable structure

Compact and hookable control panel, easy-to-operate, easy-to-maintain, high positioning accuracy, steel chassis.