MWH Series

Easy-to-use, multipurpose, precise, powerful, and high load capacity top-entry Cartesian robots, featuring an extra-strengthened mechanical structure that ensures high positional accuracy and enhanced load capacity.

MWH1800II

MWH1800II Series top-entry robots offer specifically the ideal solution for high tonnage injection molding machines.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | |||

|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | ||||

| MWH1800II | 1800 [2500] |

1500 | 3500 | 1000 – 2800 | AC Servo Motor | ±0.1 | 40 [45](*1) |

70 |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

3.3 | 4 - 6(*2) | 26.0 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

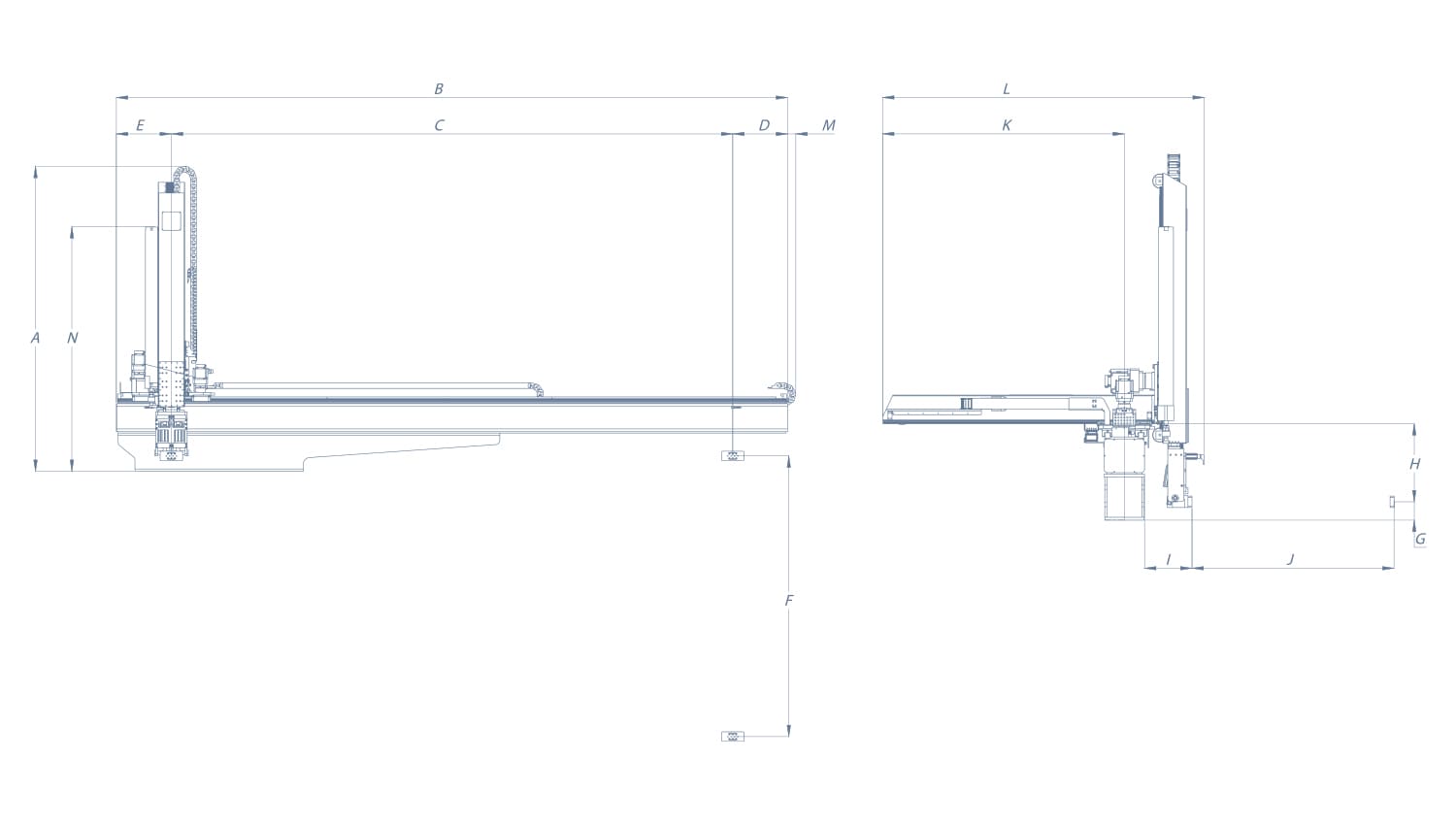

Technical drawing

MWH2500II

MWH2500II Series top-entry robots offer specifically the ideal solution for high-speed production cycles.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| MWH2500II | 2500 | 1500 | 5000 | 1300 – 2800 | AC Servo Motor | ±0.1 | 60(*1) | 535 | 2015 |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

4.1 | 4 - 6(*2) | 195.0 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

Technical drawing