SCH Series

The SCH series robots, which achieve high cycle speeds, are making a significant impact for food packaging manufacturers.

SCH1200II

SCH1200II Series top-entry robots offer specifically the ideal solution for high-speed production cycles.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| SCH1200II | 1200 [2500] |

680 | 1800 | 250-400 | AC Servo Motor | ±0.1 | 10 [45](*1) |

65 | 670 |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

4.3 | 4 - 6(*2) | 3.5 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

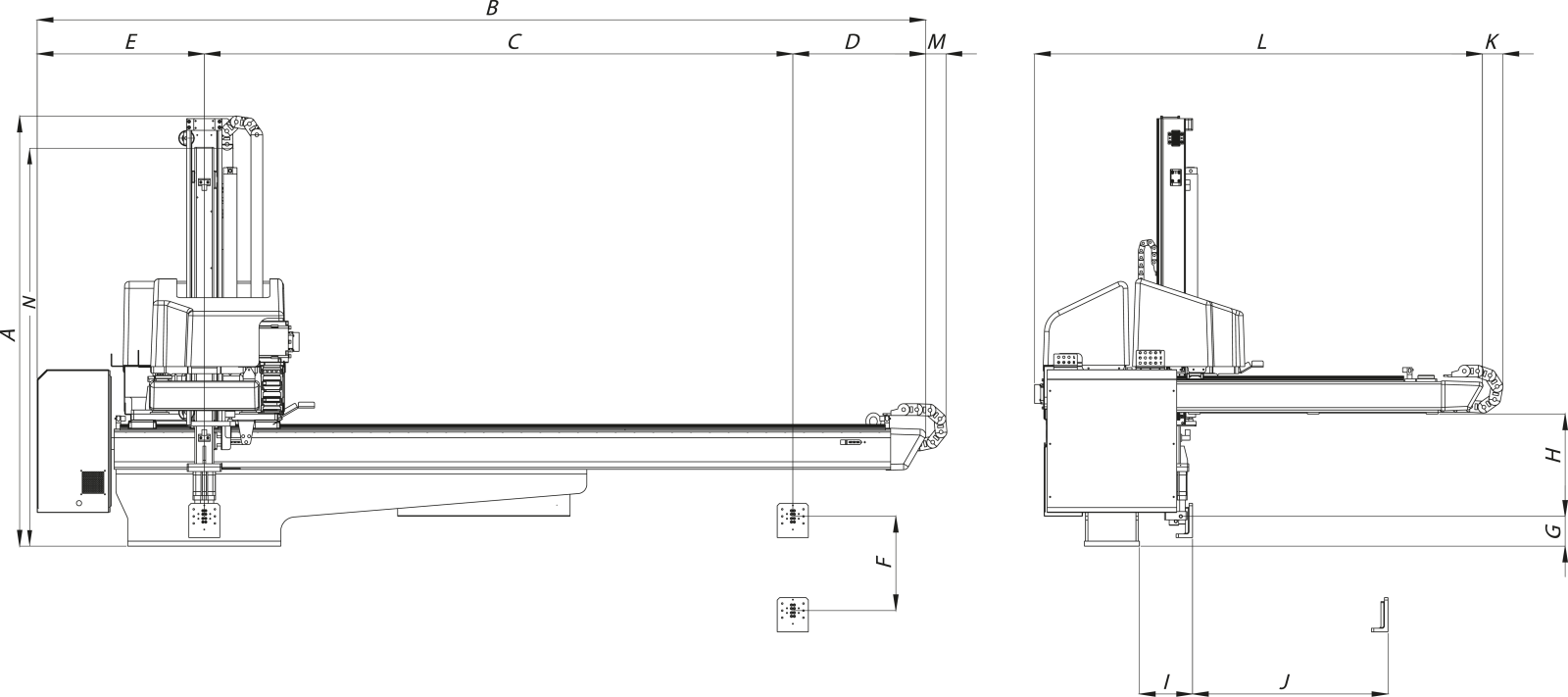

Technical drawing

SCH1600II

SCH1600II Series top-entry robots offer specifically the ideal solution for high-speed production cycles.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| SCH1600II | 1600 | 830 | 2550 | 400-850 | AC Servo Motor | ±0.1 | 35 [45](*1) |

65 | 700 |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

4.3 | 4 - 6(*2) | 3.5 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

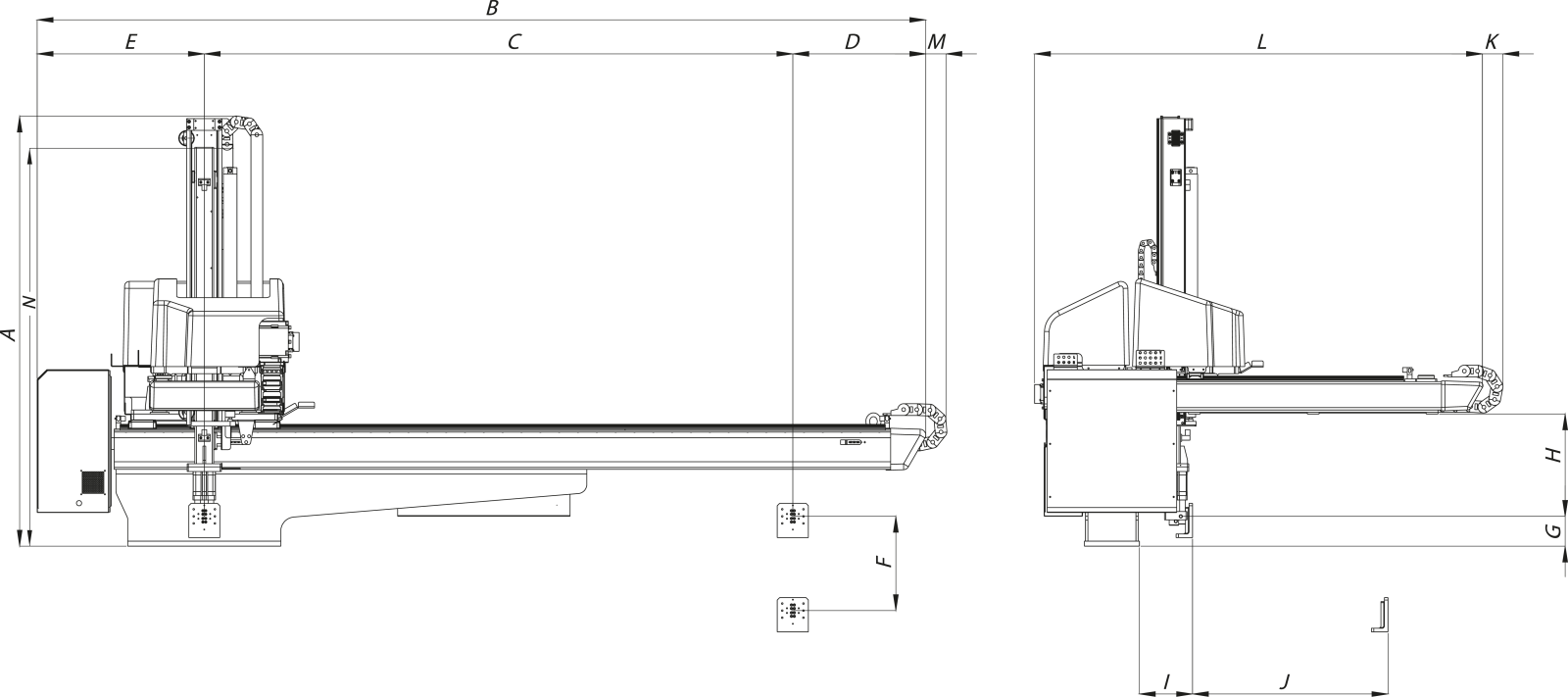

Technical drawing