MW Series

The MW series offers an ideal solution for most operations, delivering excellent performance and reliability across a wide range of industrial tasks.

MW800II

MW800II Series top-entry robots offer specifically the ideal solution for IMM Ranges until 200 Ton.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| MW800II | 800 | 440 | 1500 | 90 - 200 | AC Servo Motor | ±0.1 | 5(*1) | 35 | 305 |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

1.9 | 4 - 6(*2) | 3.5 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

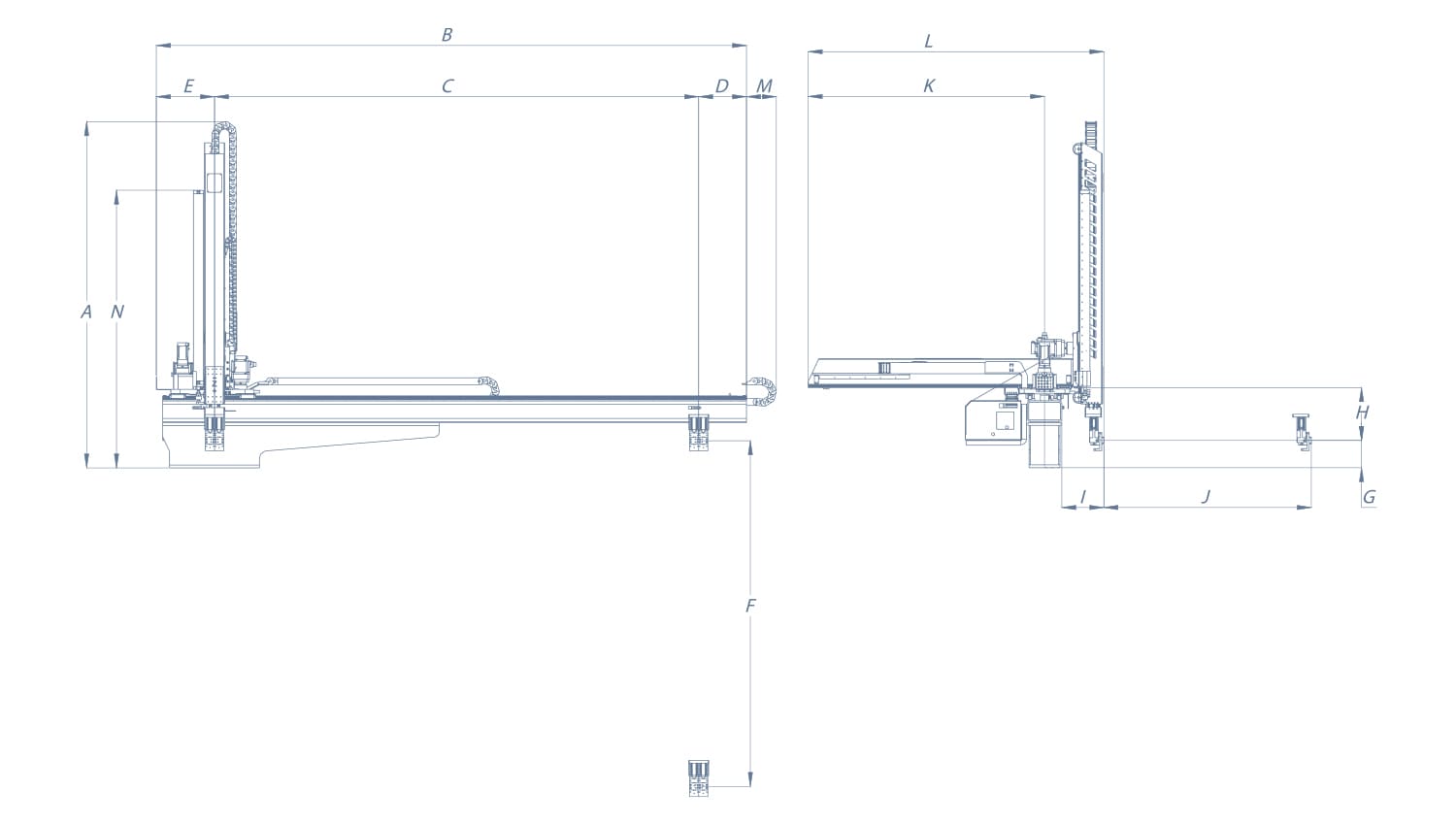

Technical drawing

MW1000II

MW1000II Series top-entry robots offer specifically the ideal solution for IMM between 150-300 Ton.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| MW800II | 1000 [1200] |

660 | 1500 [1800] [2000] |

150 – 300 | AC Servo Motor | ±0.1 | 5(*1) | 35 | 322 [325]-[345] [349] |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

1.9 | 4 - 6(*2) | 3.5 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

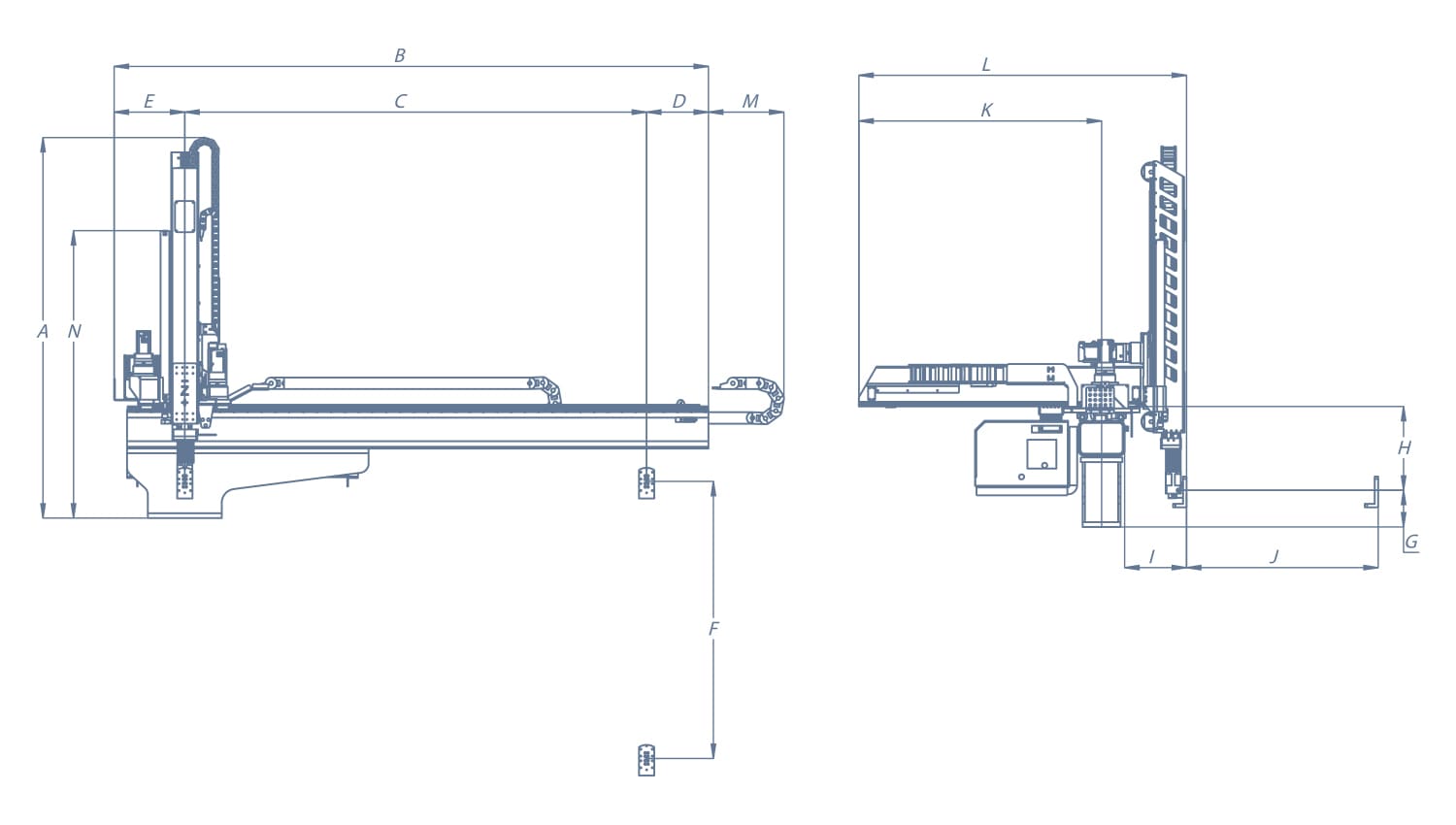

Technical drawing

MW1200II

MW1200II Series top-entry robots offer specifically the ideal solution for the IMM between 250-400 Ton.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| MW1200II | 1200 [1400] |

830 | 2000 [2500] |

250 – 400 | AC Servo Moto | ±0.1 | 10(*1) | 35 | 386 [392]-[433] [436] |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

1.9 | 4 - 6(*2) | 4.4 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

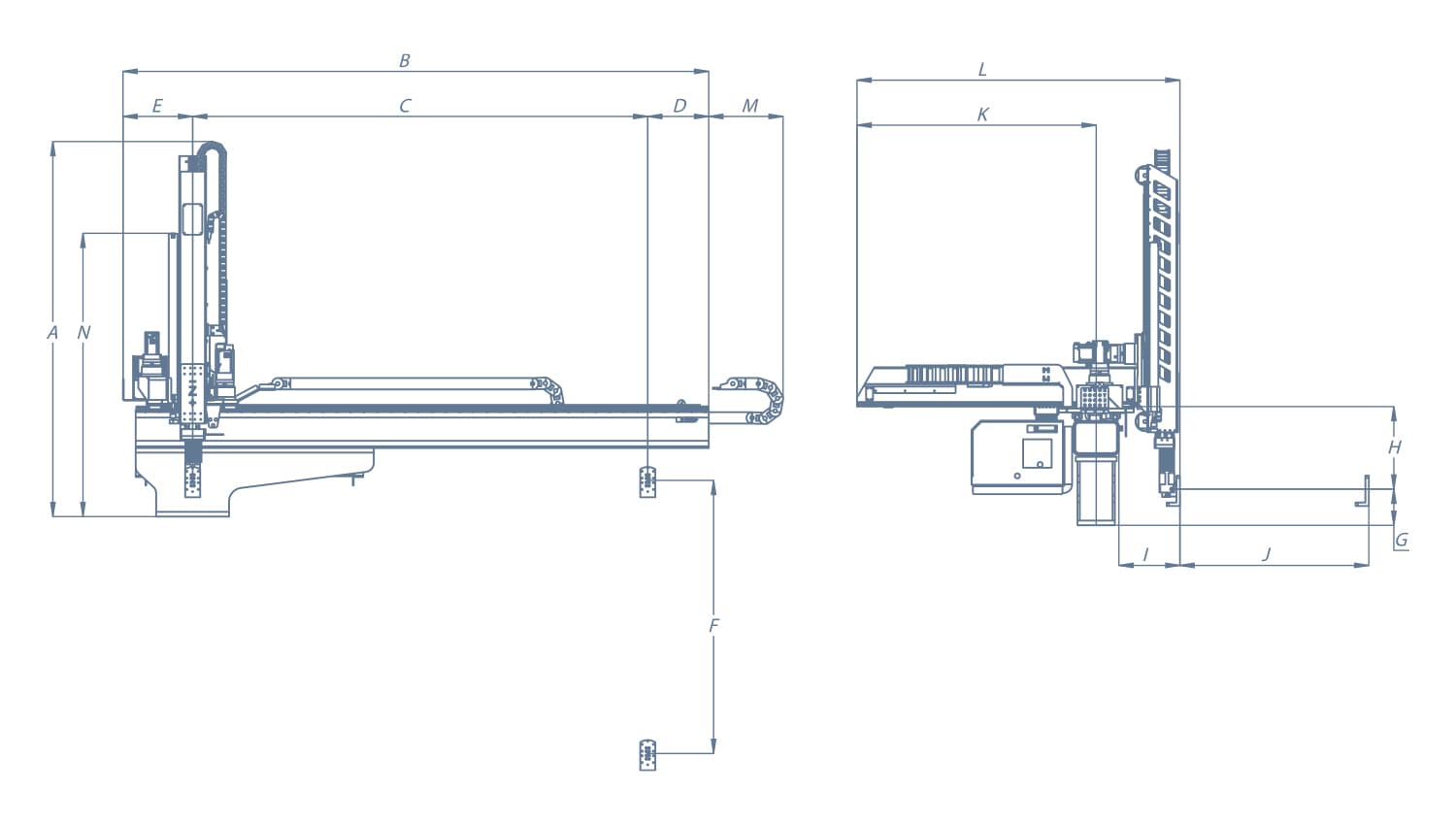

Technical drawing

MW1400II

MW1400II Series top-entry robots offer specifically the ideal solution for the IMM between 400-650 Ton.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| MW1400II | 1400 [1600] |

1000 | 2500 [3000] |

400 – 650 | AC Servo Moto | ±0.1 | 15(*1) | 35 [70] |

634 [646]-[665] [674] |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

1.9 | 4 - 6(*2) | 13.0[26.0] |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

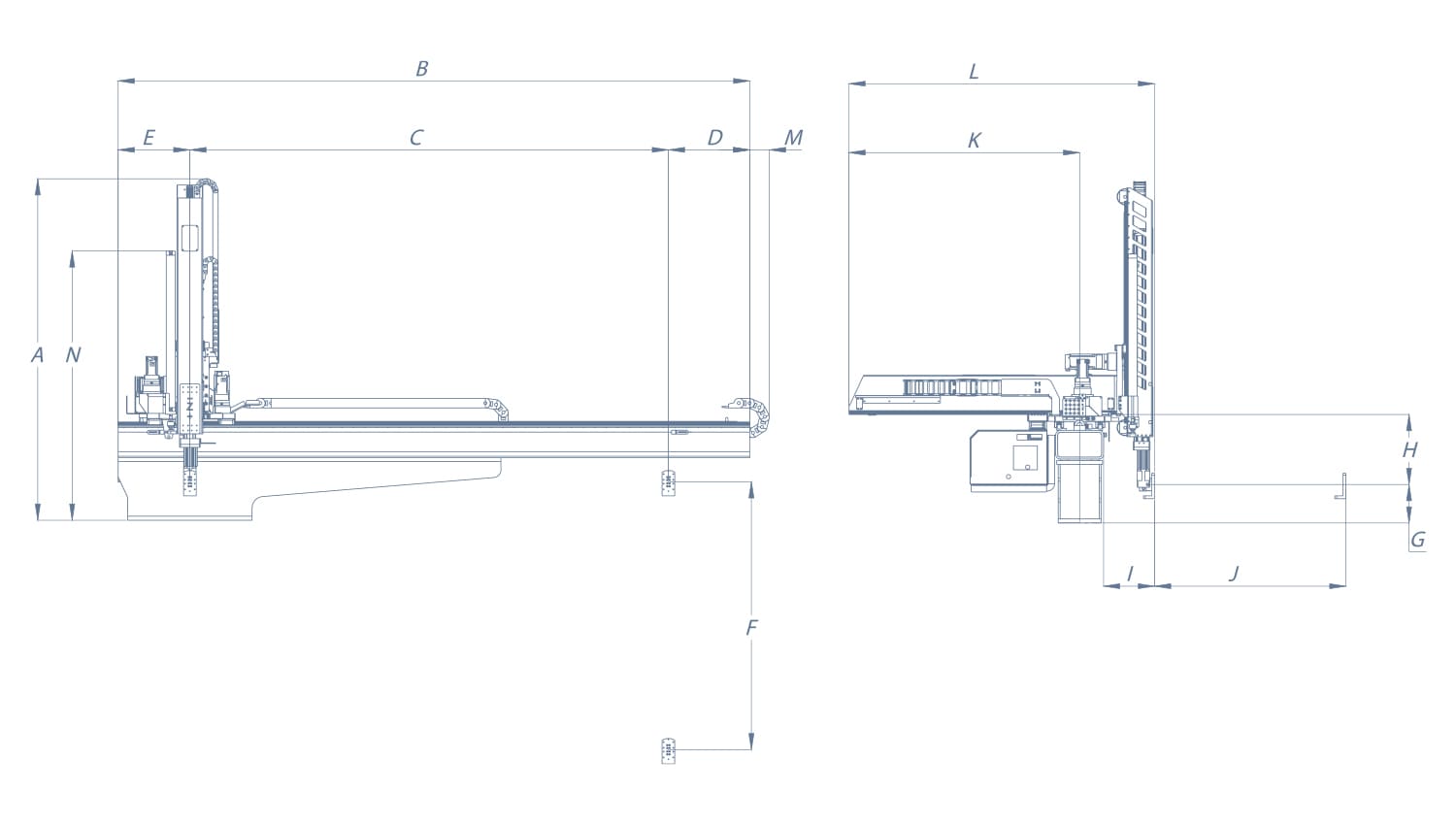

Technical drawing

MW1800II

MW1800II Series top-entry robots offer specifically the ideal solution for IMM between 650-1300 Ton.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| MW1800II | 1800 | 1300 | 2500 [3000] |

650 – 1300 | AC Servo Moto | ±0.1 | 20(*1) | 35 [70] |

656 [690] |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

1.9 | 4 - 6(*2) | 13.0[26.0] |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

Technical drawing

MW2500II

MW2500II Series top-entry robots offer specifically the ideal solution for the IMM between 1000-2800 Ton.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| MW2500II | 2500 | 1500 | 3500 [4500] |

1000 – 2800 | AC Servo Moto | ±0.1 | 25(*1) | 70 | 795 [846] |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

3.3 | 4 - 6(*2) | 26.0 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

Technical drawing