Robotic automation in plastics processing

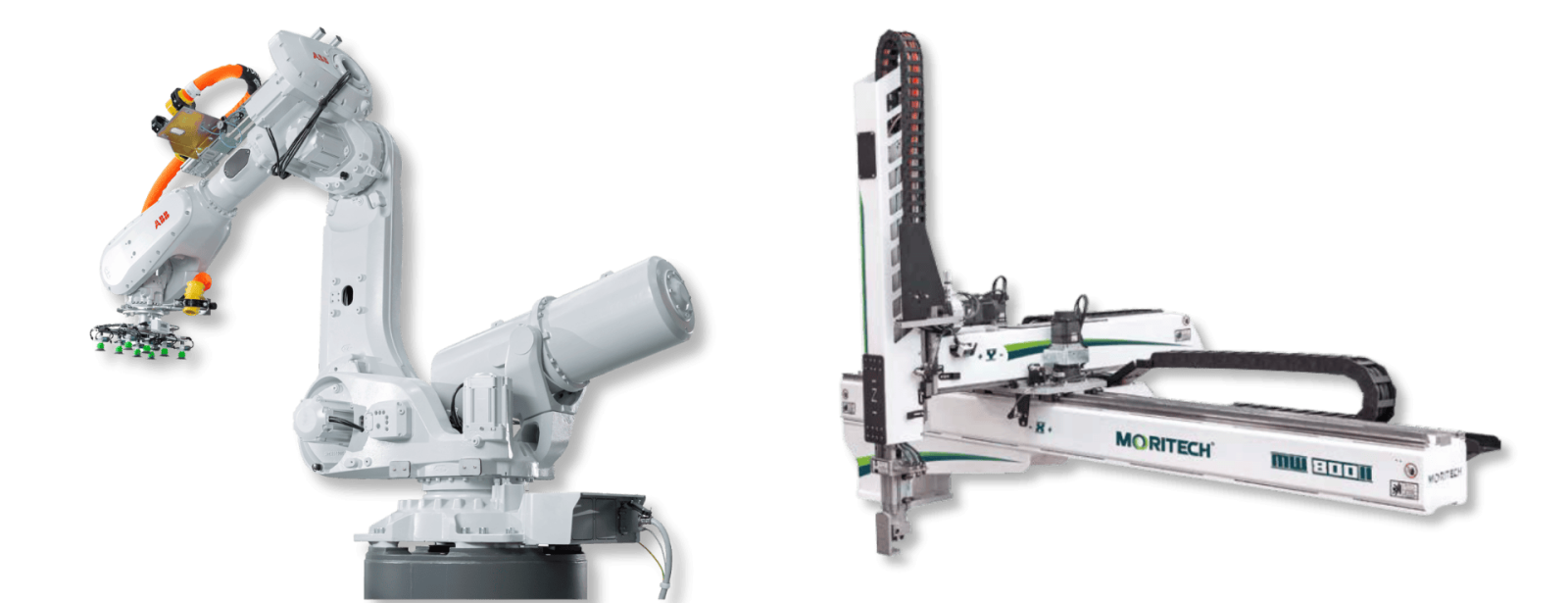

We deliver end-to-end robotization projects for injection molding and plastics processing operations. We integrate 6-axis industrial robots (including FANUC, KUKA, ABB, YASKAWA, KAWASAKI) as well as cartesian robots (including MORITECH) with injection molding machines, vision systems, packing stations, assembly workstations and belt conveyors, delivering complete, ready-to-run robotic cells.

Turnkey implementations for the plastics processing industry

Our experience includes robotization and automation of key processes in plants manufacturing plastic components - from part take-out after injection molding, through assembly and quality control, to packing finished products. As a system integrator, we deliver turnkey projects: we advise, design, install, program and service complete production workstations.

Typical implementation areas:

Robot integration with injection molding machines

Robot installation on the machine or next to it, integration of safety systems (mechanical guards, limit switches, service door interlocks, Euromap 73 / Euromap 78 safety interfaces), process integration (Euromap 12, Euromap 67 communication), and full CE certification of the entire production cell.

Quality control

Part/insert presence sensors, weight control, leak testing (air/helium) and conductivity testing, vision systems (including KEYENCE, COGNEX), color inspection, dimensional tolerances, and QR/barcode reading.

Insert molding, overmolding and hybrid assembly processes, including 2K injection molding support

Sprue removal

Mechanical cutting (cold or hot), laser cutting, deburring with milling spindles, flame treatment, and hot-air blowing.

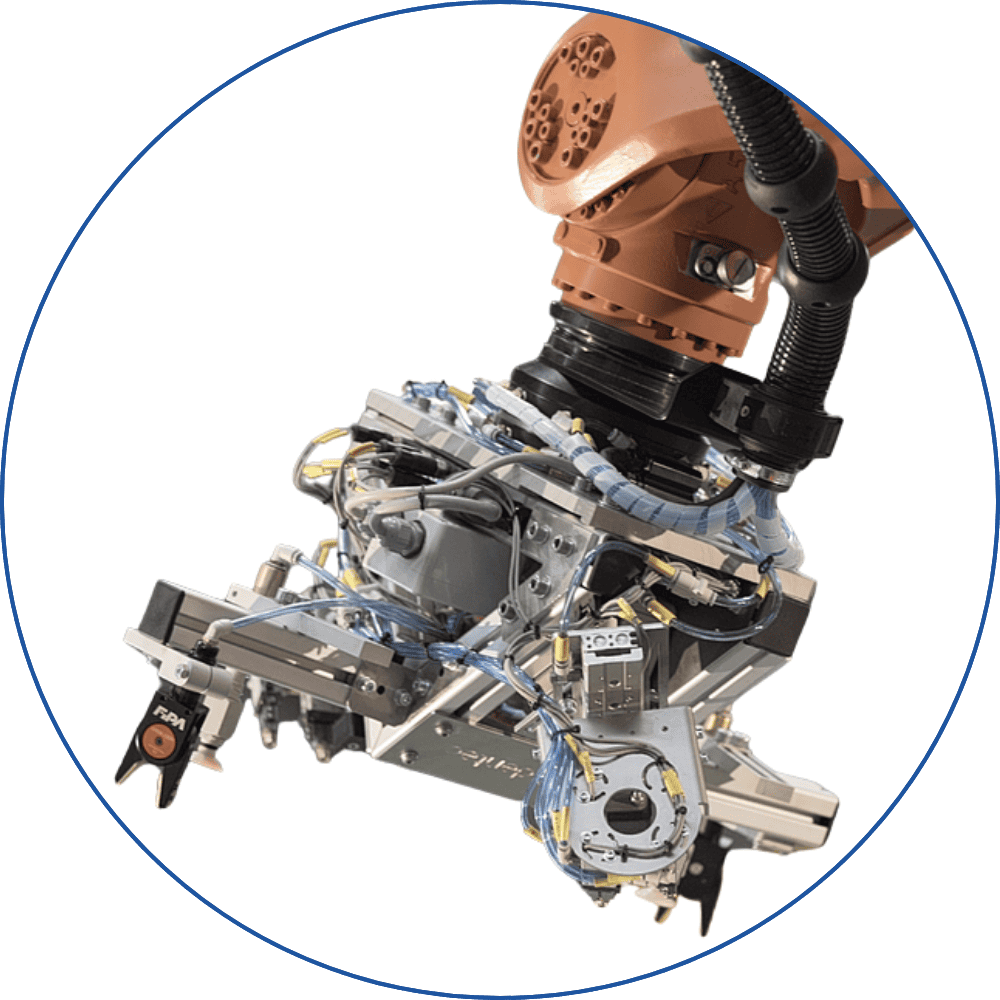

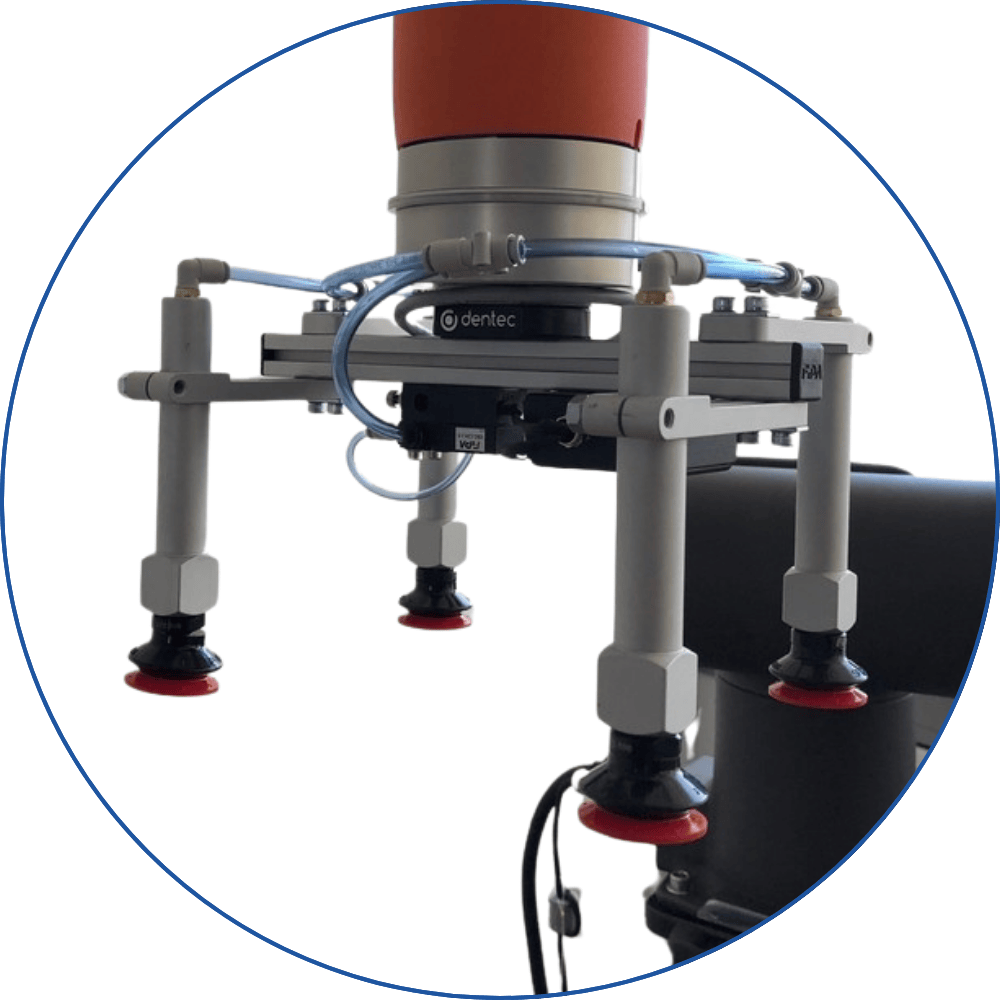

Design and build of custom end-of-arm tooling (EOAT) for part take-out

Marking systems

Labeling, laser marking, inkjet marking, pad printing.

Packing and palletizing

Boxes/bags/trays as well as dedicated trays/fixtures for repeatable part positioning in the automotive industry.

Part straightening systems

Forming jigs with optional cooling (liquid/air) or without cooling.

Part transfer and buffering between production stages

What we can robotize in your process:

6-axis industrial robots or cartesian robots take parts directly from the mold, eliminating the risk of damage and reducing cycle time. Custom-designed grippers are tailored to the part shape and temperature, as well as the number of cavities in the mold. The proven Euromap communication standard ensures reliable synchronization with the injection molding machine cycle.

Robotic systems feed and position inserts in the injection mold cavities. Inserts are separated using vibratory feeders or dedicated magazines refilled by the operator every few hours. Then inserts/inlays/pins/bushings are precisely placed in the mold by the robot. Additional vision inspection checks their position and completeness (before and after injection).

We integrate FIPA solutions for mechanical cutting and hot cutting. For more demanding processes, we use laser cutting solutions or automatic deburring with dedicated milling spindles. Depending on part weight, robot payload and mold design, cutters can be mounted on the gripper or in a dedicated station next to the injection molding machine.

Vision systems (including KEYENCE, COGNEX, OMRON and FANUC) inspect dimensions, shapes, color, presence of components, and assembly correctness. Detected defects are automatically rejected, and data can be sent to MES/OEE systems.

In our robotic cells, we very often integrate labeling systems, inkjet printers and laser markers. Depending on application requirements, the marking content is generated dynamically (e.g., date/time/unique product ID) or set as fixed. We also have extensive experience integrating robots with pad printing machines.

6-axis robots, cartesian robots and collaborative robots place parts into containers, boxes or onto pallets. The system ensures repeatability, speed and operator safety, and layer patterns can be flexibly adjusted via a dedicated HMI interface.

We design assembly stations for plastic components - automatic or semi-automatic, with operator collaboration. We often use rotary indexing tables (e.g., WEISS), pneumatic and electric drives (Festo, SMC), motors and servo drives (e.g., SEW, SIEMENS), force/torque sensors, and ultrasonic, laser or thermal welding. Our assembly stations are also frequently equipped with quality control systems based on POKA-YOKE methods.

Industrial robot integration

Dentec Robotics is an official system partner and integrator of FANUC and KUKA robots, recommended for applications in the plastics processing industry. We are experts in robotizing plastics processing operations and also have experience with other robot brands (including KAWASAKI, ABB, YASKAWA).

We equip our robotic cells with:

- Configured virtual safety zones (DCS/SafeOperation/SafeMove/FSU) - required for compact cells.

- Safety and process communication - synchronization of the robot cycle with the injection molding machine according to the selected standard (e.g., FLnet, IO-Link, Euromap 67).

- Full CE certification for the entire production cell and a safety audit according to PN-EN ISO 12100.

From design to commissioning. Turnkey implementation

What our process looks like:

- Process analysis and technical consulting - we identify needs, define key technical challenges, and set OEE and ROI targets.

- Concept design and commercial offer - selection of robot reach and payload, cell layout concept and work cycle, offline 3D simulation with cycle time estimation.

- 3D CAD design and technical consultations - engineering work on the cell structure and subsystems; at this stage, we emphasize regular project meetings with the Customer to report progress and validate design assumptions.

- Build and integration - after layout approval (design approval), we start ordering components and manufactured parts, assemble the cell, pre-fabricate the control cabinet, perform electrical and pneumatic wiring, program robots, PLC and HMI, configure safety, and run functional tests.

- FAT / SAT tests - commissioning at Dentec Robotics and at the Customer site.

- Safety audit and CE marking.

- Operator training and documentation handover.

- Service and post-commissioning support.

Customer benefits:

Cycle time reduction of up to 30-40% compared to manual operations.

Lower scrap rates and higher repeatability.

Improved safety and better workplace ergonomics.

Full integration with MES / OEE systems.

Stability and cost control in production.

Access to process data and real-time production transparency.

Safety and CE compliance

For all designed workstations, we perform risk assessment according to PN-EN ISO 12100. The process ends with a safety audit carried out by an external auditor and the issuance of a CE declaration of conformity for the entire production cell (including the injection molding machine). Each cell is equipped with safety light curtains, E-STOP switches, door interlocks and other protective elements required for the given risk category.

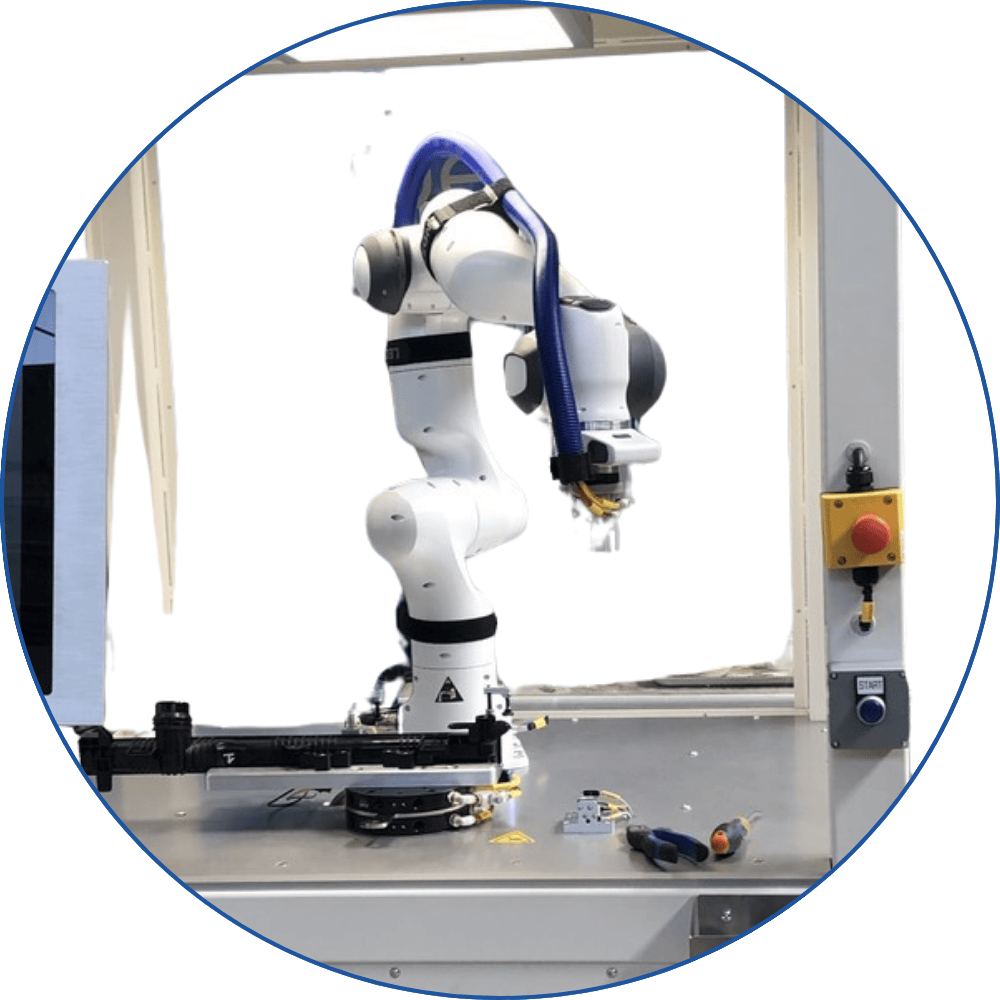

FANUC robot integration with an injection molding machine

One of our flagship implementations in the plastics processing industry is the integration of a FANUC M-20iD/25 Mate+ robot with an injection molding machine. This complete robotic cell includes Euromap communication configuration, the Dual Check Safety (DCS) system, as well as a CE audit and certification.

Depending on process requirements, the cell can be expanded with custom grippers, a sprue-cutting station, a vision system, labeling, and other automation modules. Everything is fully integrated and ready to run.

Training and service support

After commissioning, we provide:

- training for operators, programmers and maintenance personnel,

- ongoing warranty and post-warranty service,

- technical support and preventive inspections,

- access to spare parts and documentation.