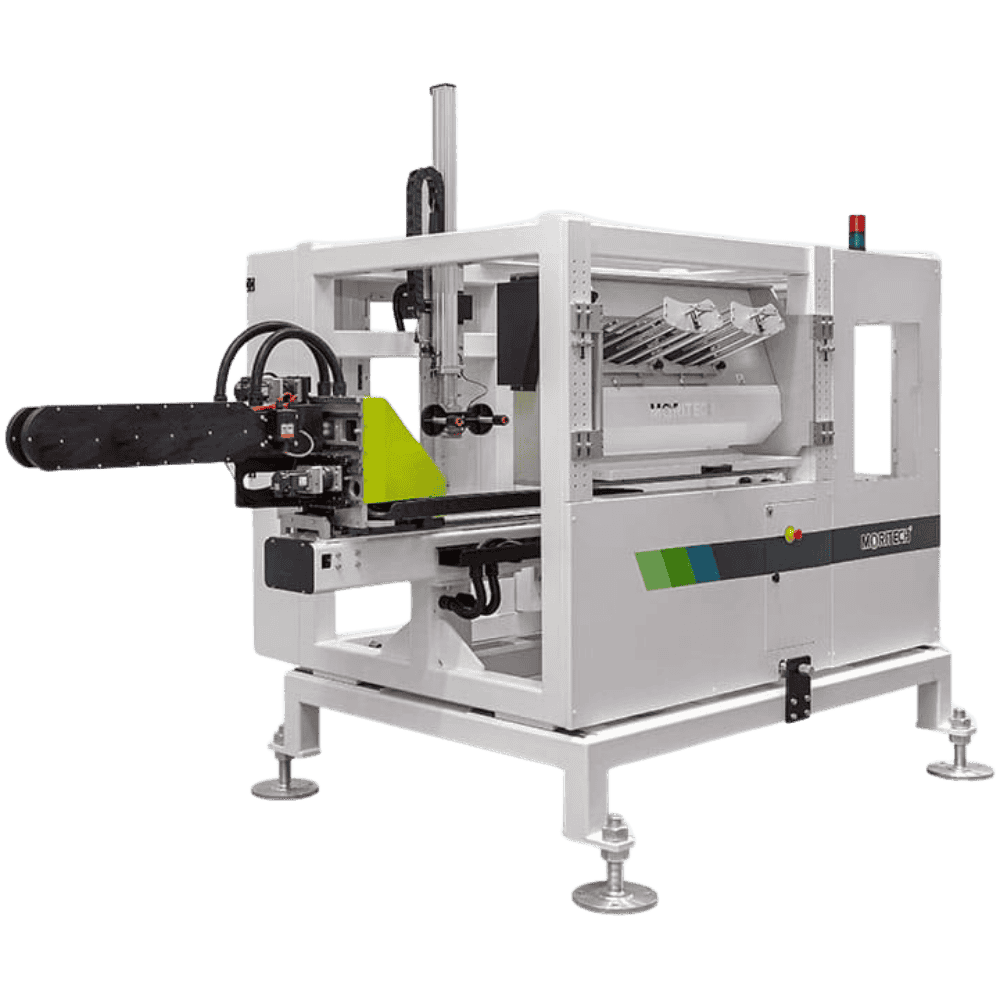

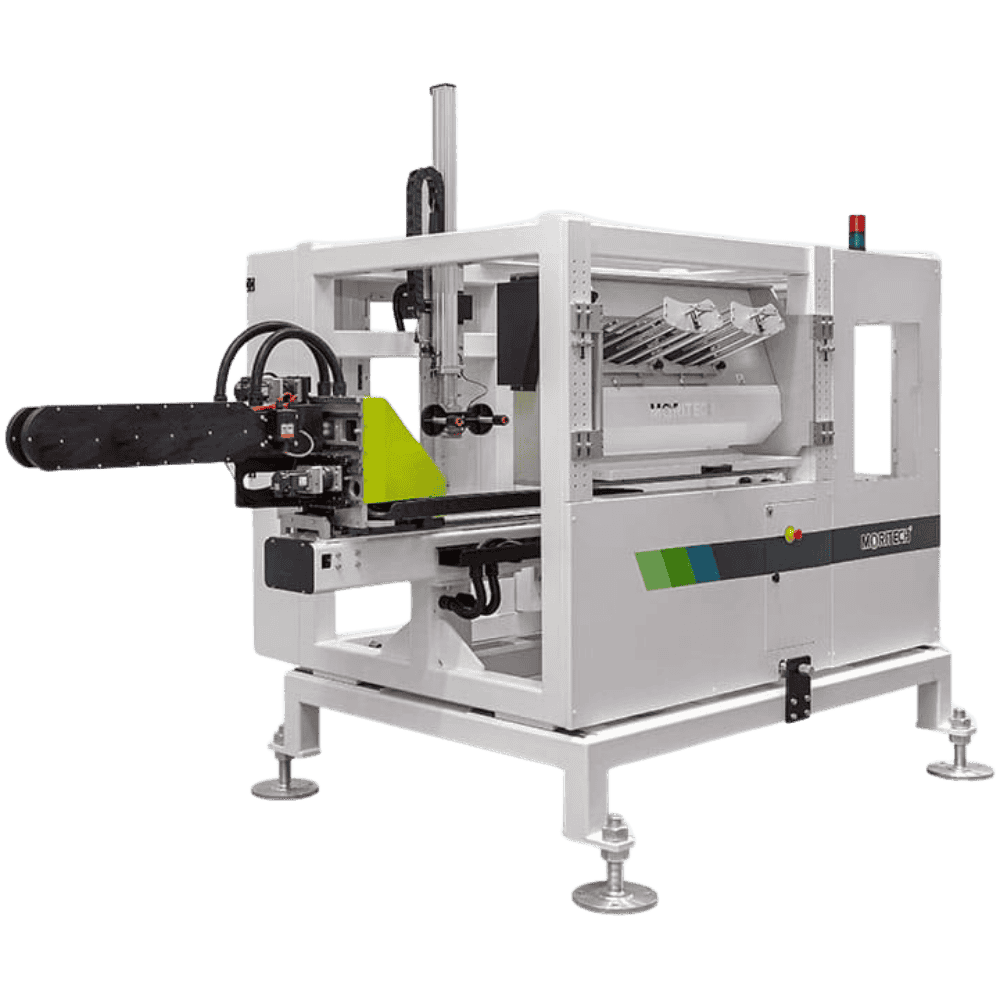

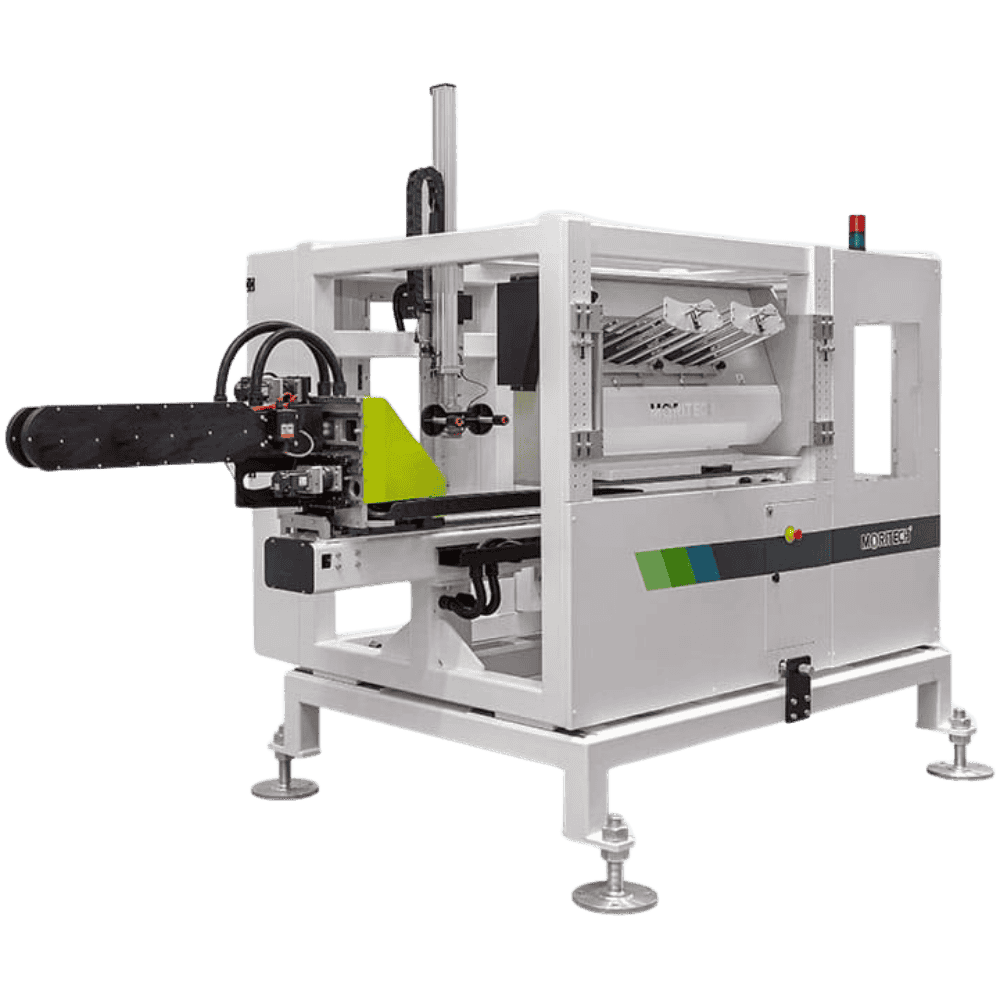

CX Series

CX Series robots offer specifically the ideal solution for high-speed production cycles, ensuring high performance while maintaining low energy consumption.

CX1800

The CX1800 side-entry robot is the ideal solution for fast production cycles in particular.

Injection tonnage: 180 to 250 tons

Dry removal cycle time: 1.1 sec.

Duration of the complete drying cycle of the robot: 1.3 sec.

| Model | Axis movements (mm) | Operating principle | Linear position repeatability (mm) | Injection tonnage (ton) | ||

|---|---|---|---|---|---|---|

| Vertical (Z) | Injection mold | Traverse (X) | ||||

| CX1800 | 600 | 230×2 | 1800 | AC servo motor, toothed wheel and toothed belt | 0.1 | 180~250 |

Minimum infrastructure requirements

| Power source | Power consumption (kVA) | Maximum power consumption (kW) | Air pressure (Bar) | Air consumption (Nl/revolution) | Net weight (kg) | |

|---|---|---|---|---|---|---|

| Main body | Switch cabinet | |||||

| Three-phase AC 380V ±10% (50/60Hz) | 3.2 | 1.9(*3) | 6~8(*4) | 2.6 | 240 | 1.1 |

(*3) The value was calculated considering approximately 60% of power consumption.

(*4) Dry air without oil and moisture is required.

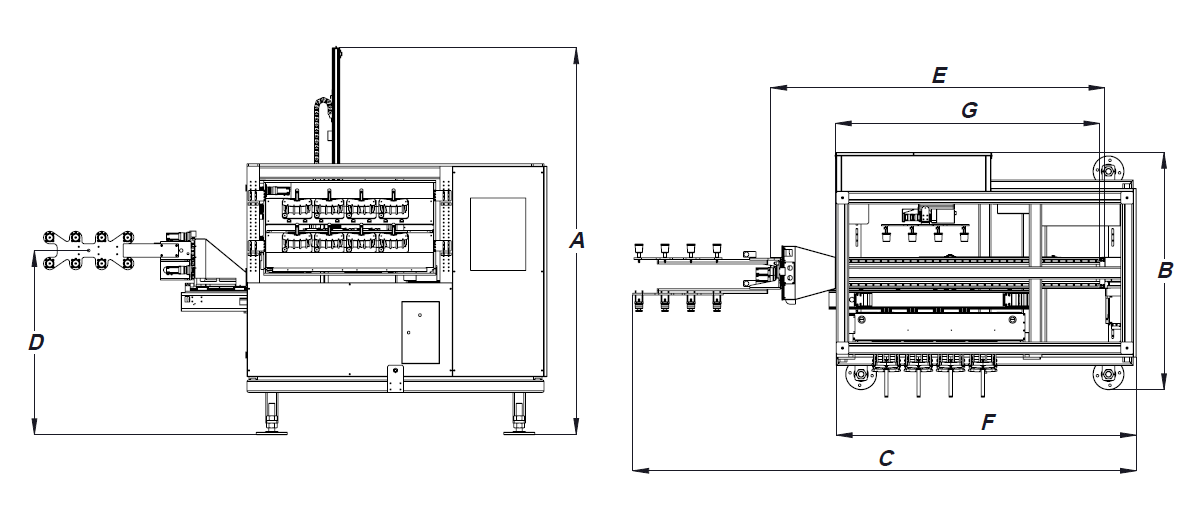

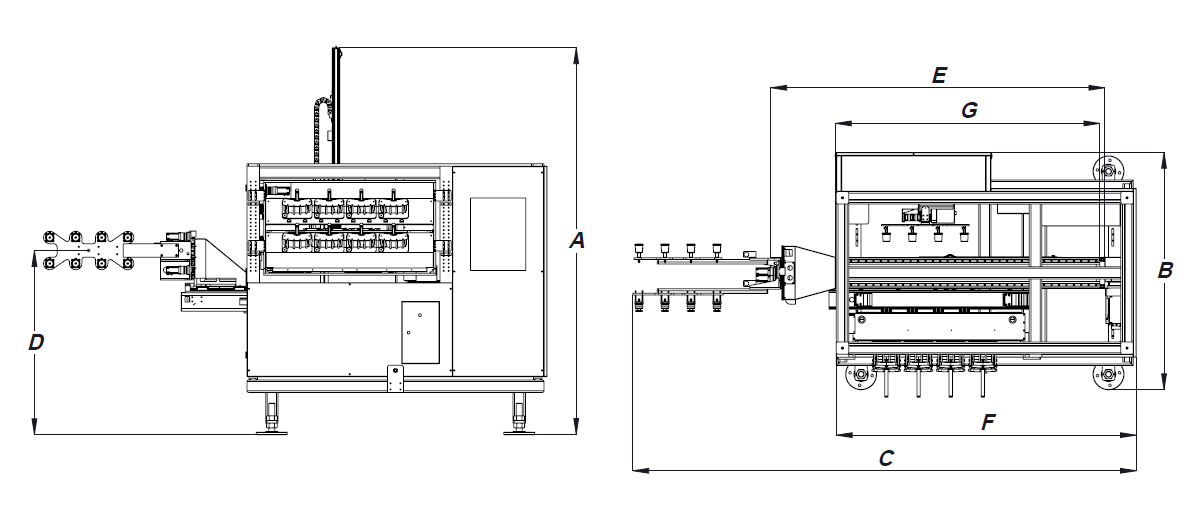

Technical drawing

CX1900

The CX1900 side-entry robot is the ideal solution for fast production cycles in particular.

Injection tonnage: 200 to 450 tons

Dry removal cycle time: 1.1 sec.

Duration of the complete drying cycle of the robot: 1.3 sec.

| Model | Axis movements (mm) | Operating principle | Linear position repeatability (mm) | Injection tonnage (ton) | ||

|---|---|---|---|---|---|---|

| Vertical (Z) | Injection mold | Traverse (X) | ||||

| CX1900 | 900 | 230×2 | 1900 | AC servo motor, toothed wheel and toothed belt | 0.1 | 200~450 |

Minimum infrastructure requirements

| Power source | Power consumption (kVA) | Maximum power consumption (kW) | Air pressure (Bar) | Air consumption (Nl/revolution) | Net weight (kg) | |

|---|---|---|---|---|---|---|

| Main body | Switch cabinet | |||||

| Three-phase AC 380V ±10% (50/60Hz) | 3.2 | 1.9(*3) | 6~8(*4) | 2.6 | 240 | 1.1 |

(*3) The value was calculated considering approximately 60% of power consumption.

(*4) Dry air without oil and moisture is required.

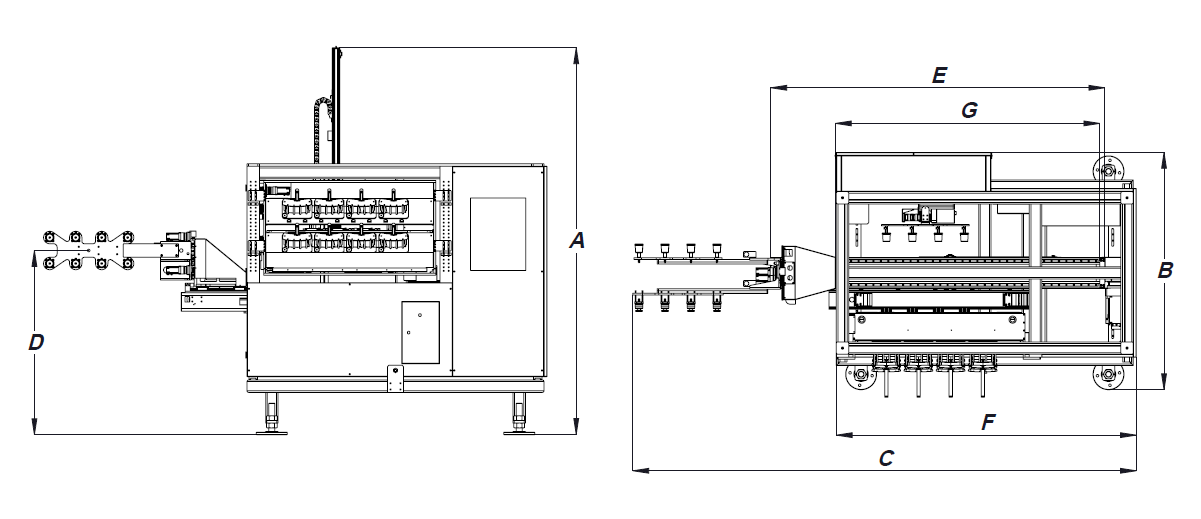

Technical drawing

CX2100

The CX2100 side-entry robot is the ideal solution for fast production cycles in particular.

Injection tonnage: 380 to 600 tons

Dry removal cycle time: 1.1 sec.

Duration of the complete drying cycle of the robot: 1.3 sec.

| Model | Axis movements (mm) | Operating principle | Linear position repeatability (mm) | Injection tonnage (ton) | ||

|---|---|---|---|---|---|---|

| Vertical (Z) | Injection mold | Traverse (X) | ||||

| CX2100 | 900 | 230×2 | 2100 | AC servo motor, toothed wheel and toothed belt | 0.1 | 380~600 |

Minimum infrastructure requirements

| Power source | Power consumption (kVA) | Maximum power consumption (kW) | Air pressure (Bar) | Air consumption (Nl/revolution) | Net weight (kg) | |

|---|---|---|---|---|---|---|

| Main body | Switch cabinet | |||||

| Three-phase AC 380V ±10% (50/60Hz) | 3.2 | 1.9(*3) | 6~8(*4) | 2.6 | 240 | 1.1 |

(*3) The value was calculated considering approximately 60% of power consumption.

(*4) Dry air without oil and moisture is required.

Technical drawing