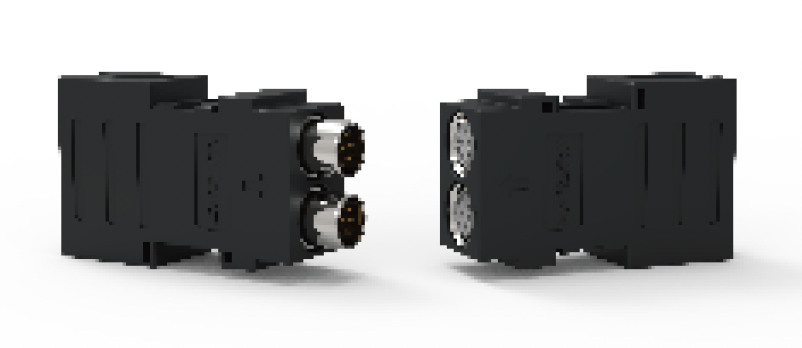

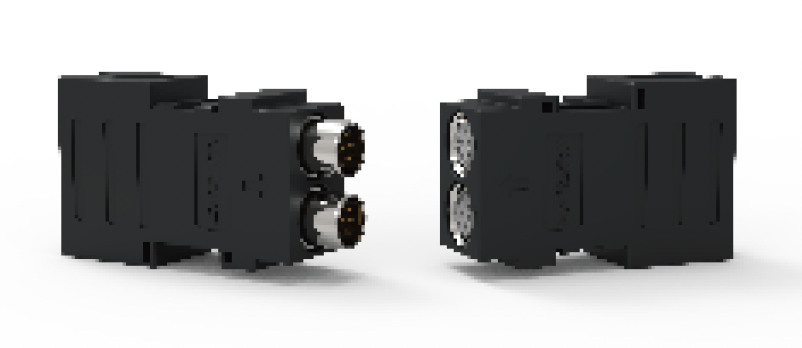

LH-TC Energy coupling device

Energy Coupling Device

The energy coupling device is a collection of multiple connection types on a single frame or housing, and can be configured according to specific specifications. It can meet the multi-function and frequent plug requirements, integrating power, signal, data, fiber, liquid and pneumatic systems. Suitable for applications which require combining electrical, power and pneumatic connections together.

.png)

High stability;

High reliability

.png)

Ultra-high plug-life

.png)

Strong current carrying capacity

.png)

Strong resistance to vibration and impact

Product introduction

| X, Y direction tolerance |

±4mm |

| Floating angle |

±1.5° |

| Position repeatability |

±0.1mm |

Φ 1.6 Signal Module

Table

|

| Mechanical parameters: |

|

| Insertion force [N] |

1 |

| Pullout force [N] |

0.5 |

| Mechanical life [times] |

≥100000 |

| Jack type |

Springtac TM |

| Electrical parameters: |

|

| Maximum continuous current [A] |

13 |

| Instantaneous current [A] |

25 |

| Contact resistance (max) [mΩ] |

25 |

| Wire specification [mm²] |

1.5 |

| Material/Coating |

Copper alloy/gold plating |

| Environmental protection requirements |

RoHS 2.0 |

|

Φ 4 Power Module

Table

.png) |

| Mechanical parameters: |

|

| Insertion force [N] |

6 |

| Pullout force [N] |

3 |

| Mechanical life [times] |

≥100000 |

| Jack type |

Springtac TM |

| Electrical parameters: |

|

| Maximum continuous current [A] |

25 |

| Instantaneous current [A] |

50 |

| Contact resistance (max) [mΩ] |

0,8 |

| Wire specification [mm²] |

4 |

| Material/Coating |

Copper alloy/gold plating |

| Environmental protection requirements |

RoHS 2.0 |

|

Φ 8 Power Module

Tabela

.png) |

| Mechanical parameters: |

|

| Insertion force [N] |

25 |

| Pullout force [N] |

15 |

| Mechanical life [times] |

≥100000 |

| Jack type |

Springtac TM |

| Electrical parameters: |

|

| Maximum continuous current [A] |

105 |

| Instantaneous current [A] |

210 |

| Contact resistance (max) [mΩ] |

0,35 |

| Wire specification [mm²] |

16/25/35 |

| Material/Coating |

Copper alloy/gold plating |

| Environmental protection requirements |

RoHS 2.0 |

|

Φ 14 Power Module

Tabela

.png) |

| Mechanical parameters: |

|

| Insertion force [N] |

40 |

| Pullout force [N] |

30 |

| Mechanical life [times] |

≥100000 |

| Jack type |

Springtac TM |

| Electrical parameters: |

|

| Maximum continuous current [A] |

400 |

| Instantaneous current [A] |

550 |

| Contact resistance (max) [mΩ] |

135 |

| Wire specification [mm²] |

50/70/95/120 |

| Material/Coating |

Copper alloy/gold plating |

| Environmental protection requirements |

RoHS 2.0 |

|

1000Mbps Network Module

Tabela

|

| Termination methods |

Welded plate |

| Mechanical property: |

|

| Mechanical life [times] |

≥50000 |

| Vibration and shock |

GB/T 21563 Class I Level B requirements |

| Electrical property: |

|

| Rated voltage |

50V |

| Rated current |

4A |

| Voltage resistance |

500V |

| Contact resistance |

≤8mΩ |

| Work temperature |

-40 °C ~ 125 °C |

| Network performance |

1000 Mbps |

| Environmental protection requirements |

RoHS 2.0 |

|

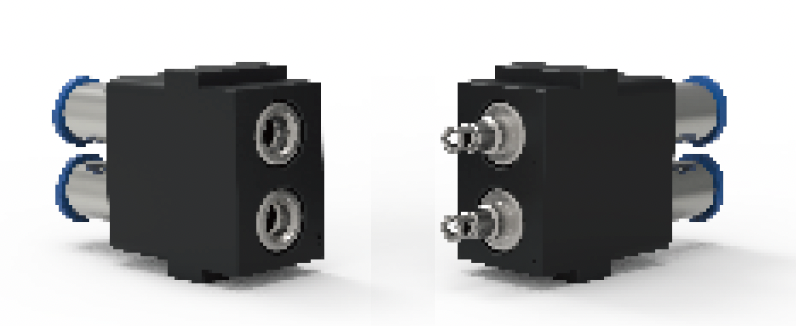

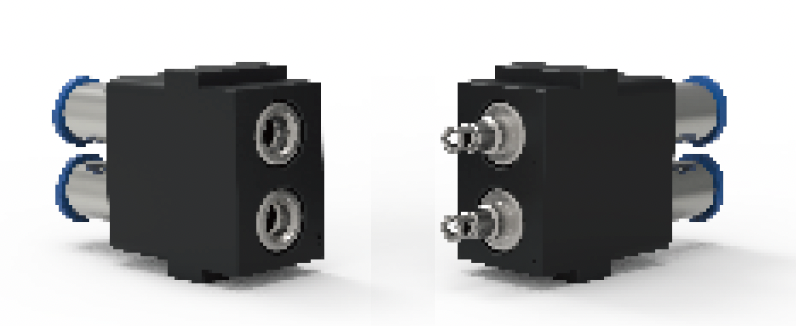

Φ3 Two-core pneumatic&liquid module

Table

|

| Used for coupling compressed air and coolant |

|

| Poles number |

2 |

| Diameter [mm] |

3 |

| Support block material |

POM |

| Max working pressure [bar] |

15 |

| Min working pressure [mbar] |

14 |

| Work temperature [°C] |

-15~90 |

| Sealing material |

NBR |

| Pipe outer diameter [mm] |

6 |

| Mechanical life [times] |

≥100000 |

|

LT-F31-BI11 Energy Connector

|

| Robot side PO: 1670 |

Tool side PO: 1671 |

| Provide energy connection between master station and slave station. |

| With X, Y, Z directional floating performance, eliminate docking error. |

| Modular design of medium unit, more flexible configuration. |

| Pass through medium such as electric power, data, i/o, air, liquid and other media. |

| Integrated tool side in position detection sensor. |

| Identification slave station number. |

|

| PO |

Model |

Configuration Parameters |

Weight (KG) |

| Robot Side |

1670 |

LT-F31-BI11-M |

2*PT3/8 self-sealed pneumatic ports

7/8-5 pin 9A independent bus power supply

M12-4-pin D-coded bus interface

Optional proximity switch

|

0.087 |

| Tool Side |

1671 |

LT-F31-BI11-T |

0.068 |

|

Compensation available:

- Compliance (X&Y-Axis): ±4mm

- Compliance (Z-Axis): +2mm

- Rotational Compliance: ±3°

- Min. Coupling Force: ≥1526N

LT-F31C Energy Connector

|

| Optional max 4 x PT1/2 pneumatic ports or Liquid ports |

| Provide energy connection between master station and slave station |

| With X, Y, Z directional floating performance, eliminate docking error |

| Pass through medium such as electric power, data, i/o, air, liquid and other media |

| Integrated tool plate in position detection sensor |

| Optional driven way: Servo Motor or Pneumatic |

|

Compensation available:

- Compliance (X&Y-Axis): ±4mm

- Compliance (Z-Axis): +2mm

- Rotational Compliance: ±3°

- Min. Coupling Force: ≥1526N

Optional configuration:

| Signal IO: |

Industrial Bus Control: |

Servo motor connector: |

Electrical power: |

Air and liquid module: |

| 19~130 channel available |

-Profibus

-DeviceNet

-EtherNet

-Profinet

-CC-Link |

Available for ABB, KUKA, Fanuc, Yaskawa Servo motor interface

Servo + signal interface is optional |

7~35 channel available |

1~4 x PT1/2 pneumatic ports or Liquid ports available |

LT-F41 Energy Connector

Product section

| Lightweight design, compact structure. |

| Realize rapid connection of energy media such as current and communication. |

| With X, Y, Z directional floating performance, eliminate docking error. |

| To realize the quick docking of energy media such as pneumatic, liquid, current and communication, etc. |

| Optional 1~ 4 channels PT1/2 pneumatic port or water port. |

| Optional driven way: servo motor or cylinder. |

Compensation available:

- Compliance (X&Y-Axis): ±4mm

- Compliance (Z-Axis): +2mm

- Rotational Compliance: ±3°

- Min. Coupling Force: ≥1526N

LT-FEC Frame

LT-FEC Frame

The LT-FEC frame consists of two aluminum guide rails and an a fixed block with a grounding guide pin. The length of the guide rail depends on the configured module.

Advantages:

- Low maintenance cost

- High safety,

- Easy to operate

| Frame floating distance (FEC frame with Φ4 ground) |

| X/Y direction |

±1mm |

| Z direction |

±0.2mm |

| Floating angle |

±1° |

| Repeatability |

±0.1mm |

| Rail length [mm] |

48/72/96/144/156/174 |

Φ 4 Ground Pin

Table

|

| Mechanical capacity: |

|

| Insertion and extraction force [N] |

4-8 |

| Mechanical life [usage times] |

≥100000 |

| Work Environment: |

|

| Work temperature |

-40°C~+125°C |

| Material/Coating/Appearance: |

|

| Pinhole parts/terminals |

Copper alloy, plated with silver |

| Standard and certification: |

|

| Environmental requirement |

RoHS 2.0 |

|

Water&Pneumatic Interface

Tabela

.png)

|

|

LH-L01BMH/LH-L01BTH |

LH-L01B06MH/LH-L01B06TH |

| Diameter [mm] |

8 |

6 |

| Max pressure [MPa] |

1.6 |

1.6 |

| Connection force without pressure [N] |

150 |

112.5 |

| Repulsive cross-sectional area [cm²] |

4.35 |

3.26 |

| Service life [million times] |

100 |

100 |

|

Hydraulic Interface

Tabela

.png)

|

|

LTPH08 |

LTPH08B |

LTPH12 |

LTPH12B |

| Diameter [mm] |

8 |

12 |

| The size of the interface |

G1/2 |

G3/4 |

| Connection force without pressure [N] |

163 |

210 |

| Socket/Plug repulsive cross-sectional area [cm²] |

2.14 |

4.52 |

| Flow [speed 5m/s] [l/min] |

16.49 |

37.31 |

| Insertion and extraction service life [number] |

≥100000 |

| Max pressure [MPa] |

16 |

25 |

16 |

25 |

|

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)

.png)

.png)