Blog

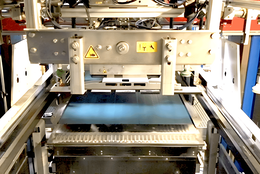

Case Study: How we robotized a difficult injection molding process with inserts at Metchem

In the plastics processing industry, rising labor costs and quality requirements, especially in the automotive sector, force manufacturers to take decisive steps toward modern technologies. As Dentec, we have specialized in the automation of production processes and injection molding machine operation using robots since 2016. We want to show you the behind-the-scenes of our implementation at Metchem, where the use of a 6-axis robot allowed for the realization of a complicated project that was unattainable for traditional methods.

Case study: More Order, More Safety: ENGEL and Sumcab Enable Validated Retrofit Solution for Handheld Devices

Damaged cables on the robot control unit or loose cables as tripping hazards – many, operators of injection molding systems are familiar with these everyday challenges. This is why ENGEL and Sumcab have now deepened their partnership, addressing this very interface: For current ENGEL robot systems, the MTPReel retraction system has already been an established solution. Following joint validation and final approval by ENGEL, it can now also be used without issue for retrofitting existing machines. For production managers and maintenance teams, this means an easy-to-implement improvement in terms of safety, reliability, and user convenience.

Case study: Vacuum system upgrade in a brewery - 80% less compressed air consumption thanks to FIPA components

In an existing brewery facility, the system for handling intermediate layers made of large cardboard sheets was modernized. By implementing a compact multi-stage FBM vacuum ejector and new bellows vacuum cups made of TPU from FIPA GmbH, compressed air consumption was reduced by approximately 80% – while improving overall process reliability.

Result: significant energy savings, lower operating costs, and a meaningful contribution to climate protection.

Safety first: New antistatic vacuum cups for damage-free handling of electronic components

In our product range, FIPA offers flat, bellows, and oval vacuum cups made of conductive silicone or NBR. The electrically conductive materials of the body and sealing lip effectively protect against electrostatic discharges (ESD), which can cause irreversible damage to electronic components. ESD is one of the most common causes of failure, especially in semiconductor integrated circuits.

When installation space is tight: New area gripper picks up narrow parts safely and reliably

Handling wooden panels in the furniture industry is a tricky business. A variety of formats, different surface coatings and a dusty production environment place high demands on gripper systems. In a modernised feeding system at furniture manufacturer BMG, FIPA area grippers from the FSG series make a significant contribution to reducing downtimes.

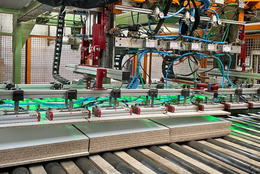

Case study - Area grippers are the key to reducing downtime | Safe and reliable feeding of chipboard

Handling wooden panels in the furniture industry is a tricky business. A variety of formats, different surface coatings and a dusty production environment place high demands on gripper systems. In a modernised feeding system at furniture manufacturer BMG, FIPA area grippers from the FSG series make a significant contribution to reducing downtimes.

FIPALIFT Vacuum lifters - Light and efficient work

According to Statistics Poland (GUS), from January to September 2023, the accident rate per 1,000 employees was as high as 3.22. On paper, this figure might not seem significant, but in reality it’s a serious problem, especially in the industrial sector. Workers often ignore safety rules to meet production targets. FIPALIFT vacuum lifters can help prevent such accidents while also increasing overall productivity. How is that possible?