eMW Series

A cost-effective automation solution, offering efficiency and reliability without compromising performance. Ideal for businesses looking to optimize operations affordably.

eMW800

eMW800 Series top-entry robots offer an ideal and cost-effective solution for simple pick-and-place operations for IMM 50 to 150 Ton.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| eMW800 | 800 | 450 | 1200 | 50 – 150 | AC Servo Motor | ±0.1 | 3(*1) | 25 | 260 |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

1.3 | 4 - 6(*2) | 2.5 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

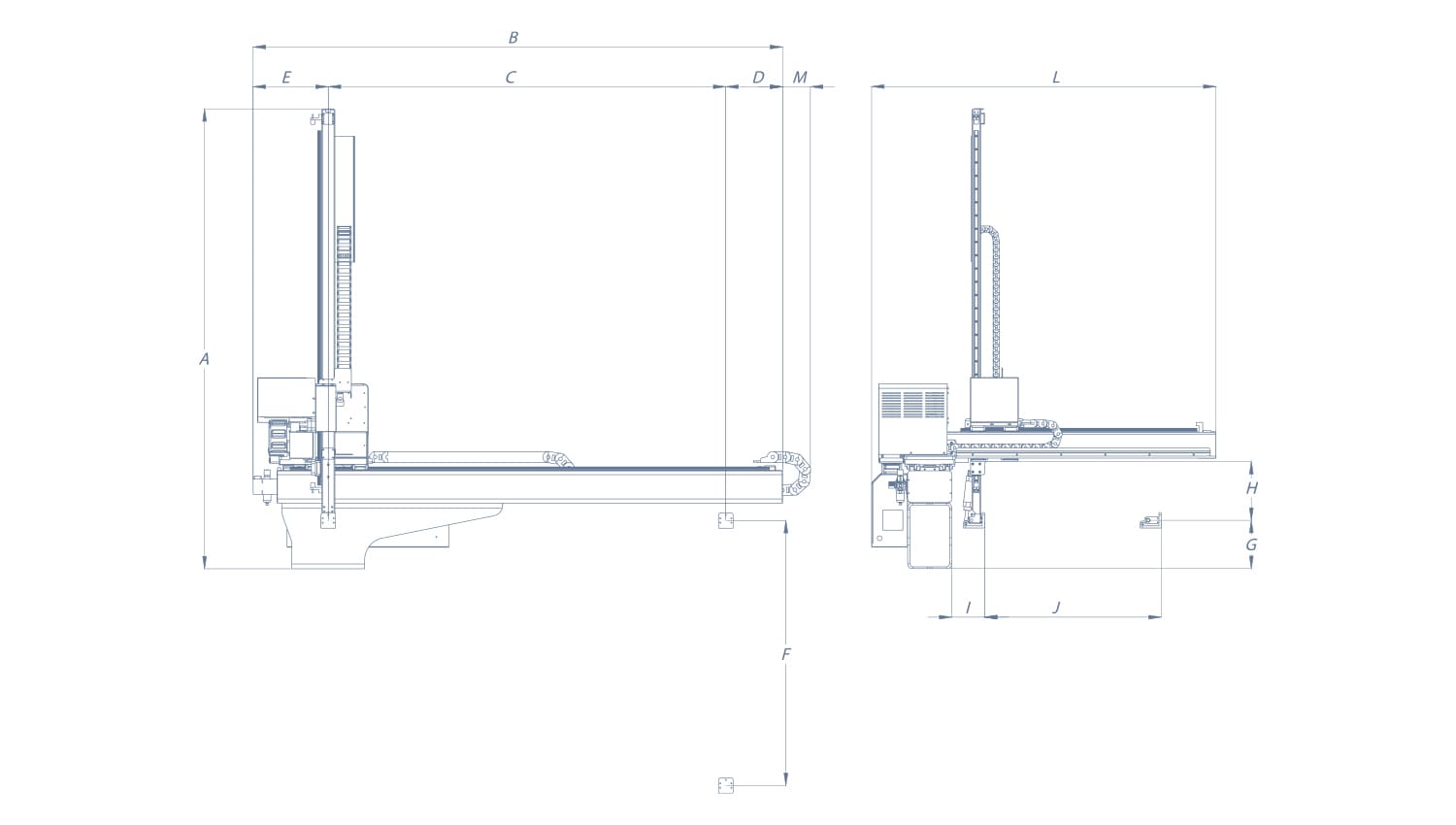

Technical drawing

eMW1000

eMW1000 Series top-entry robots offer an ideal and cost-effective solution for simple pick-and-place operations for IMM 100 to 380 Ton.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| eMW1000 | 1000 | 660 | 1500 | 100 – 380 | AC Servo Motor | ±0.1 | 6(*1) | 25 | 280 |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

1.3 | 4 - 6(*2) | 3.5 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

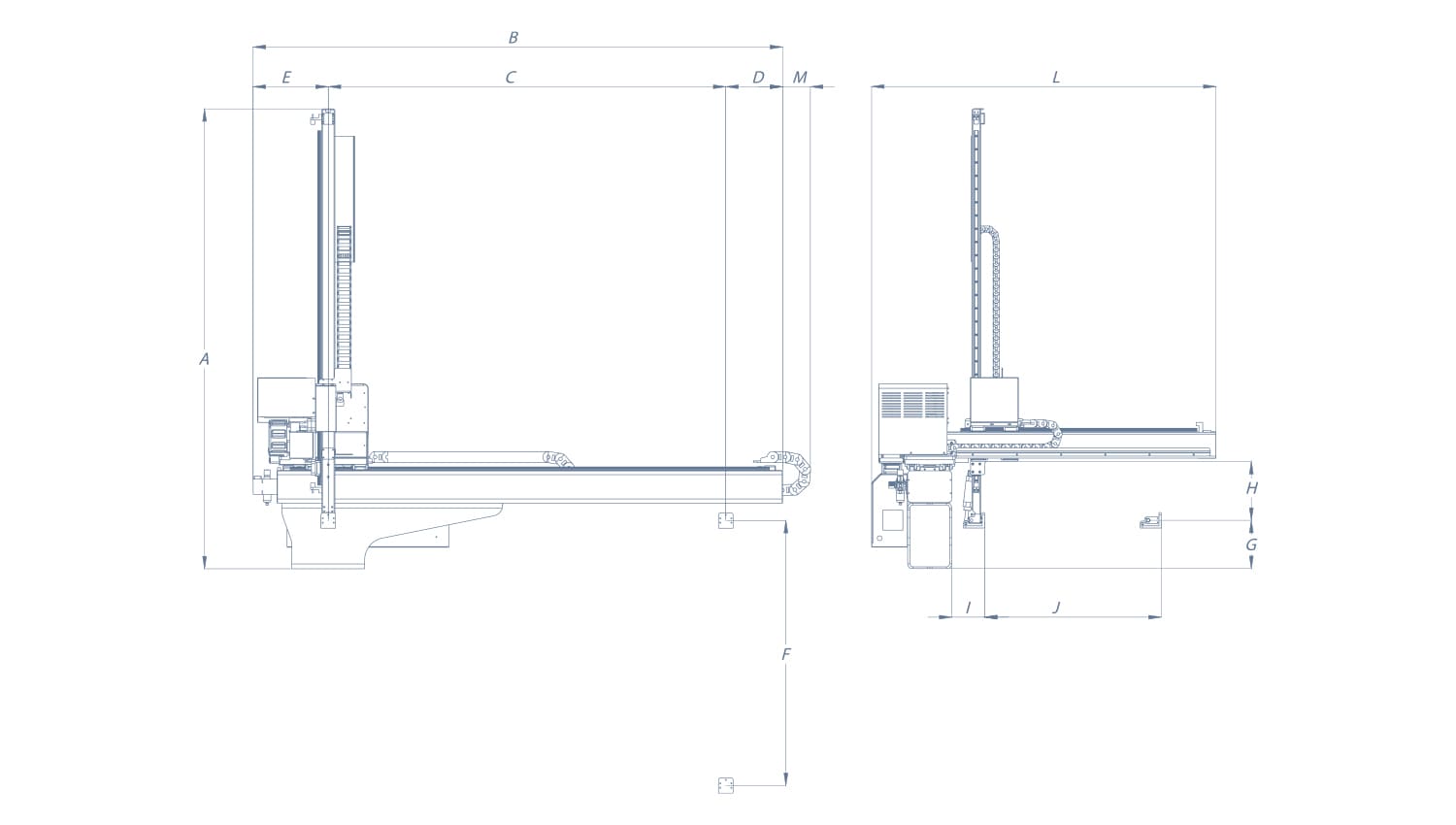

Technical drawing

eMW1200

eMW1000 Series top-entry robots offer an ideal and cost-effective solution for simple pick-and-place operations for IMM 300 to 660 Ton.

| Model | Axis Strokes (mm) | Clamping Force Range (tons) | Driving Method | Linear Position Repeatability (mm) | C-Axis Posture (90°) | Net Weight of Main Body (kg) | |||

|---|---|---|---|---|---|---|---|---|---|

| Vertical (Z) | Crosswise (Y) | Traverse (X) | Maximum Payload (kg) | C-Axis Torque (Nm) | |||||

| eMW1200 | 1200 | 800 | 1800 | 300 – 660 | AC Servo Motor | ±0.1 | 12(*1) | 25 | 310 |

(*1) Weight of robotic arm is included.

Minimum infrastructure requirements

| Power Supply | Maximum Power (kW) | Air Pressure (Bar) | Air Consumption (Nl/Cycle) |

|---|---|---|---|

| Three-phase AC 380V ±10% (50Hz / 60Hz) |

1.6 | 4 - 6(*2) | 4.5 |

(*2) Need for Pressurized Air Purified (Dried) from Oil and Humidity Exists.

Technical drawing