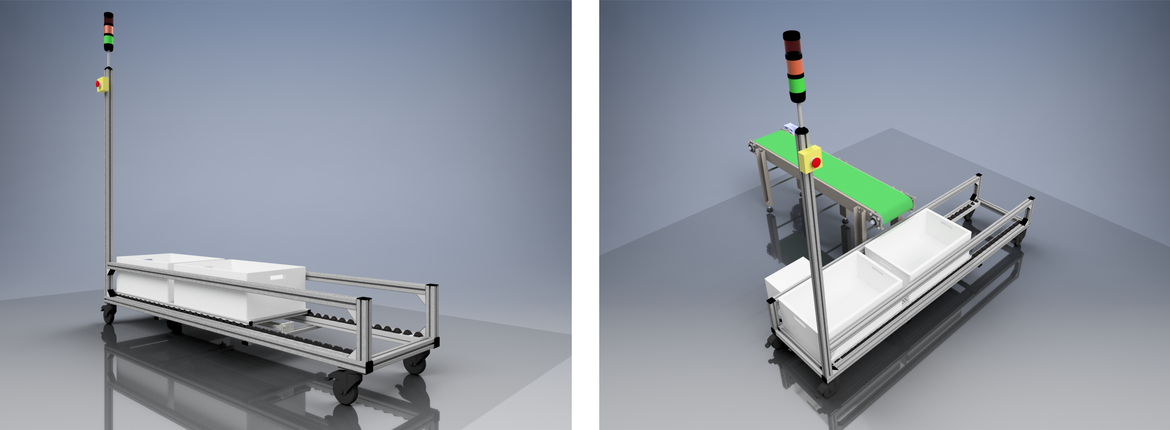

Collecting unit CU

Description

CU collecting unit assists the operator and ensures continuity of production by reducing downtime associated with the exchange of full collective box into empty one. CU unit communicates with external devices (robot, injection molding machine, etc.) and in the event of receiving information about filling the container, stops the transporter, puts a new container on and resumes conveyor. Optionally, the device can be equipped with a scale or a part counter placed on the conveyor preceding the CU module.

Functions

• Designed to work with EURO containers in 4 standard sizes

• Communication with production devices

• Conveyor stopping for the time of box switching

• Light signaling (box full)

• Transporter stop time less than 5s at maximum speed

Options

• Dimensions modifications for containers of non-standard size

• Adapters for non-standard boxes

• Sound signaling

• Checkweigher for counting details in containers

• Retrofitting modules for receiving and storing containers on stacks

• Collecting and exporting statistics

• HMI screen for displaying statistics