Floating position compensation devices

The floating compensation devices are mainly used to improve machining accuracy and process reliability, especially when processing deformation sensitive workpieces, the biggest advantage is the ability to respond to workpiece position deviations flexibly through the floating compensation function, while ensuring the stability and durability of the clamping force, thereby extending the equipment maintenance cycle time, reducing maintenance costs, and improving overall machining efficiency.

Key differentiators

Compensate the position error during assembly and loading precisely.

Support position compensation in X&Y, Z, X&Y&Z directions, ensure wide and flexible compensation ability.

Ensure the operation is exact by locking the center point and position storing function.

ISO9409 interface to simplify assembled process.

Adopt firm material, improve the service life of equipment.

.png)

Floating compensation devices in X&Y Directions

| Model | LT-COMP-50XY | LT-COMP-63XY | LT-COMP-80XY |

| Compensation in X and Y directions | ±2.5mm | ±3mm | ±4mm |

| Rotate angle | ±12° | ±12° | ±16° |

| Recommended handling weight in straight direction | 6kg | 9kg | 15kg |

| Recommended handling weight in horizontal direction | 4kg | 6kg | 10kg |

| Recommended handling weight in the storing position | 1.5kg | 1.8kg | 4kg |

| The locking force of located piston | 240N | 380N | 610N |

| The Max locking payload | 130N | 200N | 310N |

| The piston force of storing position | 145N | 240N | 590N |

| The Max radial force in storing position | 40N | 70N | 175N |

| The rotate moment in the Max storing position | 1.2N.m | 1.7N.m | 4N.m |

| The Min/Rated/The Max work air pressure | 0.3/0.6/0.8MPa | 0.3/0.6/0.8MPa | 0.3/0.6/0.8MPa |

| Repeatability | 0.1mm | 0.1mm | 0.1mm |

| The flange in the robot side | ISO 9409-1-50-4-M6 | ISO 9409-1-63-4-M6 | ISO 9409-1-80-6-M8 |

| Product weight | 0.45kg | 0.82kg | 1.43kg |

| The lowest/The highest environmental temperature | +5/+60℃ | +5/+60℃ | +5/+60℃ |

| Dimension | Φ65×48mm | Φ80×56mm | Φ100×62mm |

Floating compensation devices in Z Direction

| Model | LT-COMP-50Z-1/LT-COMP-50Z-2 | LT-COMP-63Z-1/LT-COMP-63Z-2 | LT-COMP-80Z-1/LT-COMP-80Z-2 |

| Compensation in Z direction | 8mm | 8mm | 10mm |

| Recommended handling weight | 5kg | 9kg | 12kg |

| The locking force in retraction state (under 0.6MPa) | 280N / 260N | 630N / 590N | 1160N / 1140N |

| The locking force in extended state(under 0.6MPa) | 510N / 530N | 900N / 920N | 1500N / 1520N |

| The Min spring force | 20N / 40N | 40N / 60N | 70N / 90N |

| The Max spring force | 40N / 60N | 60N / 100N | 100N / 120N |

| The Min/Rated/The Max work air pressure | 0.3/0.6/0.8MPa | 0.3/0.6/0.8MPa | 0.3/0.6/0.8MPa |

| Repeatability | 0.02mm | 0.02mm | 0.02mm |

| The flange in the robot side | ISO 9409-1-50-4-M6 | ISO 9409-1-63-4-M6 | ISO 9409-1-80-6-M8 |

| Product weight | 0.6kg | 1kg | 1.7kg |

| The lowest/The highest environmental temperature | +5/+60℃ | +5/+60℃ | +5/+60℃ |

| Dimension | 67.5×67.5×53mm | 82.5×82.5×59.5mm | 105×105×65mm |

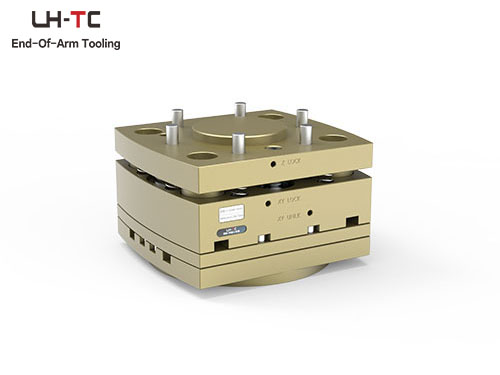

Floating compensation devices in X&Y&Z Directions

| Model | LT-COMP-100XYZSeries | LT-COMP-125XYZSeries | LT-COMP-160XYZSeries | LT-COMP-200XYZSeries |

| Compensation in X and Y directions | ±4mm | ±7mm | ±10mm | 12mm |

| Compensation in Z direction | 10mm | 12mm | 14mm | 14mm |

| Recommended handling weight in straight direction | 9kg | 18kg | 60kg | 160kg |

| Recommended handling weight in horizontal direction | 5.5kg | 11kg | 40kg | 100kg |

| The locking force in X and Y directions | 633N | 1224N | 1847N | 2787N |

| The locking force in Z direction | 871N | 1584N | 2080N | 3176N |

| The radial force of position memory piston | 180N | 260N | 334N | 521N |

| The Min/Rated/The Max work air pressure | 0.3/0.6/0.8MPa | 0.3/0.6/0.8MPa | 0.3/0.6/0.8MPa | 0.3/0.6/0.8MPa |

| The work temperature | +5/+60℃ | +5/+60℃ | +5/+60℃ | +5/+60℃ |

| Repeatability | 0.1mm | 0.1mm | 0.1mm | 0.1mm |

| Flange standard | ISO 9409-1-100-6-M8 | ISO 9409-1-125-6-M10 | ISO 9409-1-160-6-M10 | ISO 9409-1-200-6-M12 |