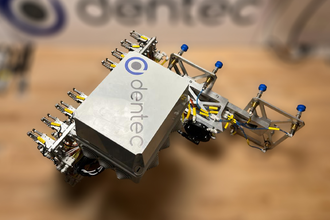

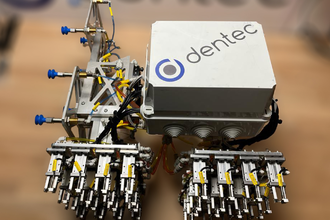

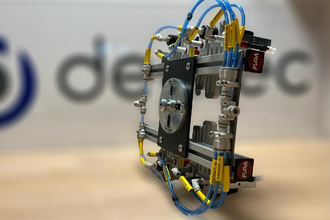

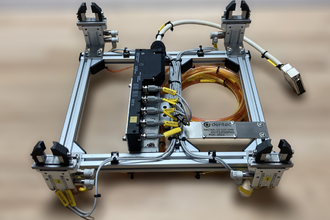

Gripper assembly

Dentec offers versatile goods and services in the field of design and construction of grippers for manipulators and industral robots. As a base for projects we use components of renowned German company, FIPA, which allows us to provide our grippers highest precision and durability.

Components that are used in the construction of FIPA grippers:

Reliable connection between the robot and the gripper system, even under heavy workloads and frequent tool changes. Minimal downtime.

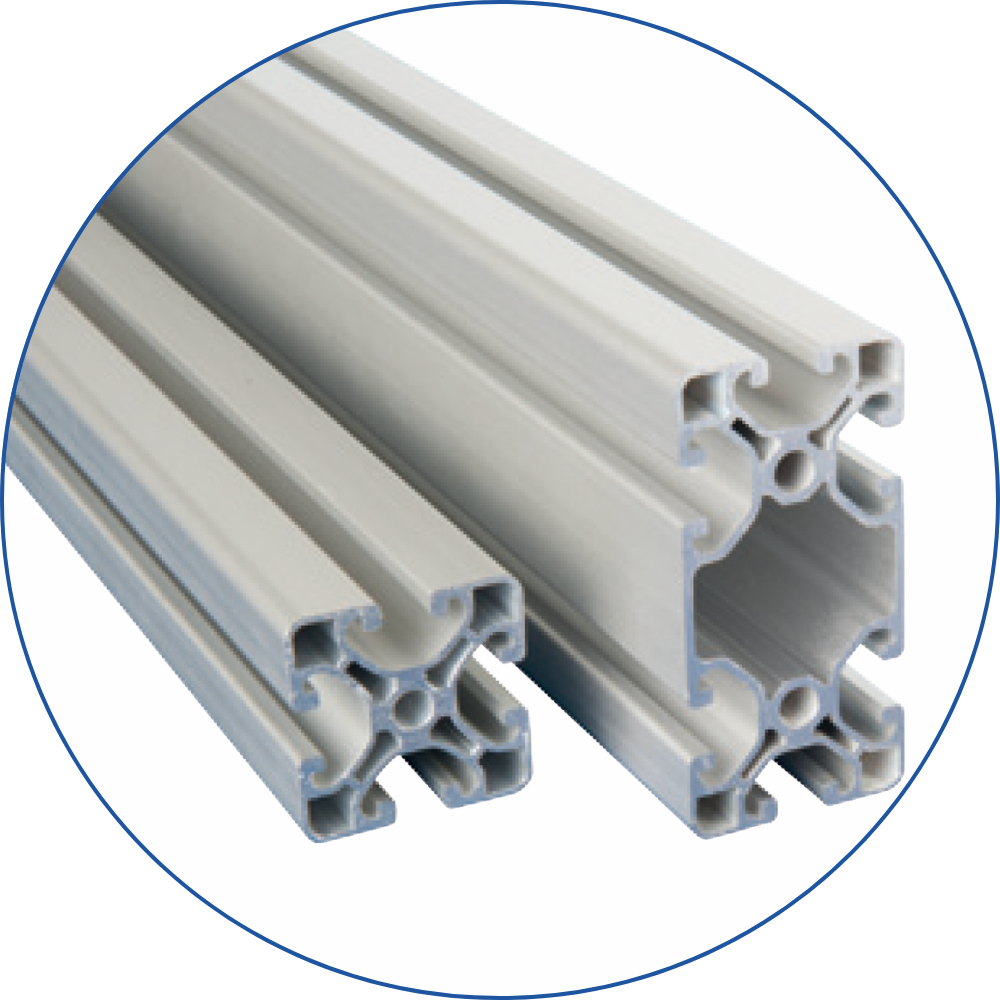

Profiles are a fundamental element of the gripper system. FIPA profiles ensure a lightweight yet stable structure and offer flexibility for easy expansion.

Secure gripping of components. Thanks to their slim design, finger grippers are also suitable for confined workspaces. High reliability due to their robust durability.

FIPA offers a wide range of grippers that enable the precise removal of parts from injection molds. With their robust construction, sprue grippers provide a strong grip and long service life.

A wide selection of manual and automatic cutters, along with suitable blades for trimming injection molding flash. Universal mounting.

Suction cups made from high-temperature-resistant materials do not leave marks on the handled parts, enabling subsequent painting or coating.

FIPA mounting brackets allow the integration of grippers and suction cups into a unified gripping system. They ensure maximum functionality and reliability.

A wide range of flexible pressure hoses and cables. Functional screw and plug connectors for precise couplings."

As a part of the cooperation customer can count on:

- Solution proposal that take into consideration specific requirements of the application, i.e. cycle time, required precision, work with fragile components etc.

- 3D-CAD drawings for proposed solution,

- Proven solution ( tests of gripper prototype we will perform in our lab and at customer side),

- Technical suport for individual customer projects,

- High quality of used components,

- Construction, assembly and start od work with gripper on manipulator and robots,

- Sevice and spare parts stock.

To fit our offer for yours expectations we prepared three proposals of cooperation in the range of grippers engineering:

DENTEC will consult with you and deliver all necessary gripper components. You will takeover the planning and construction of the gripper system.

DENTEC will design the grippers using 3D CAD software and supply you with all of the required components as well as instructions for assembling the grippers. You assemble the gripper system yourself.

DENTEC manages all of the steps for realising the gripper system – from planning through to assembly and delivery. The only thing to happen on-site, may be fine tuning.

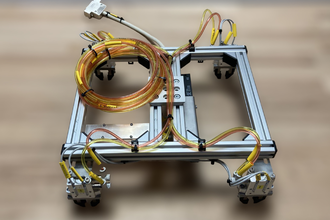

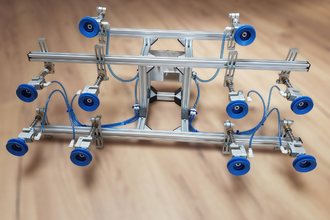

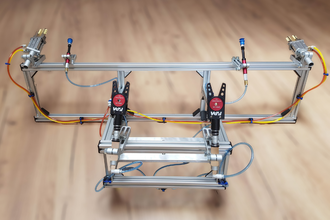

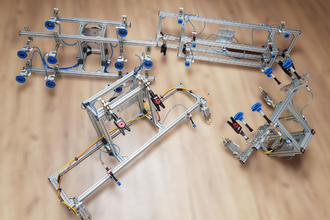

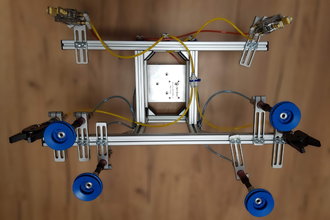

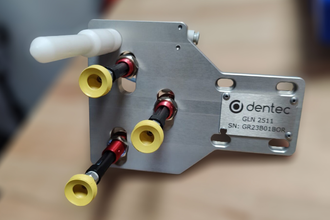

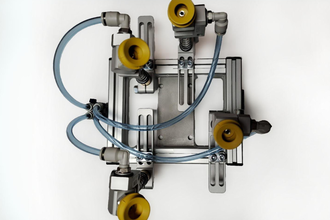

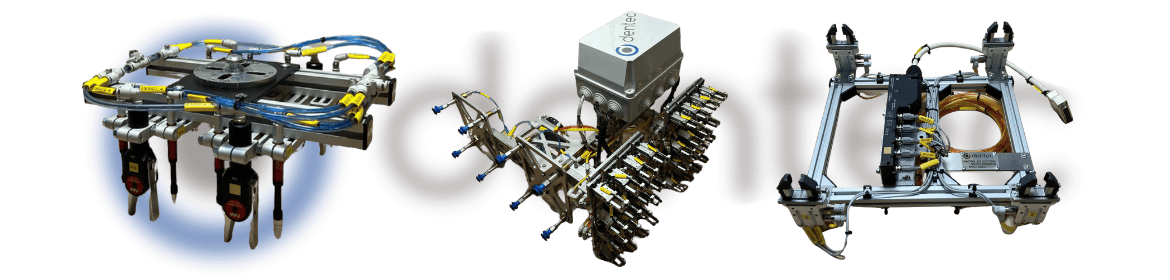

Our sample projects

We invite you to explore our gripper projects that showcase how we tailor solutions to different needs and industries. Each project is a response to a specific challenge, ensuring our grippers perform reliably even in the most demanding production environments.

Photos: