Series CL-M1

CL-M1 Series – Vacuum Lifters for Wall Panels

The CL-M1 series includes a wide range of models with a single vacuum cup, offering a maximum load capacity of up to 750 kg. This vacuum lifter is powered by a long-lasting, rechargeable battery (220 V charger included). The manual tilting system allows for vertical and horizontal movement. The lift is equipped with an audio-visual alarm system that warns the operator of possible dangers. In addition, the vacuum gauge with coloured scale enables constant monitoring of the vacuum level. The lifter's longevity is also guaranteed by a dust and condensation filter system.

Specifications:

- Horizontal and vertical lifting

- Manual tilt 0–90°

- Single suction pad

- Max capacity 750 kg

- Safety systems

| Application | Wall panels |

|---|---|

| Capacity | Up to 750 kg |

| Suction pads | Single suction pad |

| Load movement | Manual tilt 0–90° |

| Power supply | Battery |

| Vacuum system | Vacuum circuit complete with vacuum reserve and non-return valve |

| Weight | Depends on model |

| Control | Manual valve on the lifter’s frame Release of the load by dual action security command |

| Standard features | On-off double sliding valve with safety Audible and visual low vacuum warning devices Vacuum gauge with coloured scale, vacuum filter, non-return valves |

Model CL-W

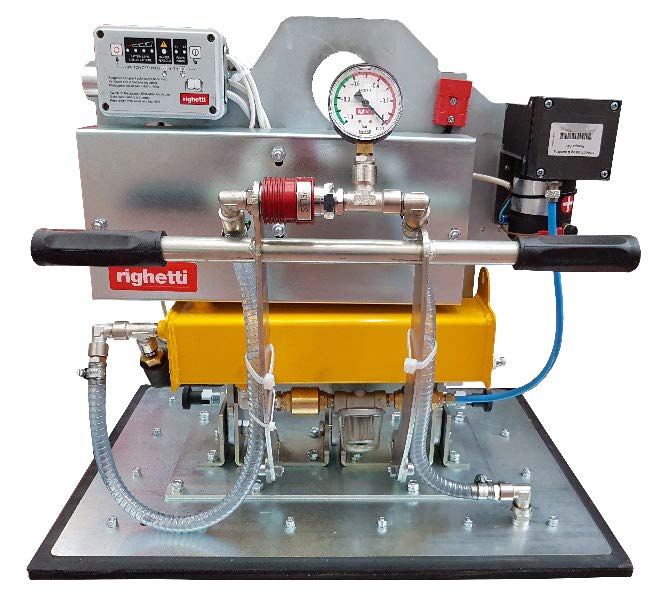

The CL-W model is a cladding vacuum lifter specific for handling and laying wall panels, assembling cold rooms or handling glass sheets

Thanks to the dual vacuum circuit in compliance with European standards EN13155 and the sophisticated safety systems, the Righetti CL-W Cladding Vacuum Lifter is suitable for use on construction sites.

The tilting mechanism allows panels to be moved safely from a horizontal to a vertical position, a movement essential for the installation of wall panels. The suction pad is suitable for both smooth and micro-ribbed panels commonly used in the construction of sheds, warehouses, cold rooms, and other types of cladding. The removable suspension helps reduce the total height below the hook, making the device easier to operate in limited vertical spaces. The vacuum unit is fully self-powered by built-in, rechargeable, and easily replaceable batteries. Integrated safety systems constantly monitor the proper functioning of the lifter, while vacuum gauges with colored scales—installed on each vacuum circuit—ensure continuous control of the vacuum level. The device is also equipped with an advanced filtration system for dust and condensation, which can be quickly and easily cleaned. A radio remote control is generally included as standard, although a manual control version is also available upon request.

Specifications:

-

Tilt system 0-90°

-

Dual vacuum circuit built to EN13155 standard

-

Radio remote control as optional

-

Trolley for transport

-

Safety systems

-

Removable suspension

Accessories included:

Accessories suitcase

Practical suitcase for safely carrying a spare battery kit and charger.

Removable suspension

The CL-W model allows the suspension to be removed, significantly reducing the height below the hook.

Spare battery kit

Additional set of high-capacity batteries for easy replacement of discharged batteries without interrupting work.

External charger

External charger to keep the spare battery kit ready for use.

Optional to choose:

-

Remote control

-

Additional alarm

-

Transport trolley

| Application | Installation of insulated wall panels horizontally and vertically Smooth and micro-ribbed panels |

|---|---|

| Capacity | Max 375 kg |

| Suction pads | 1 vacuum pad (1000×500 mm) Divided in 4 areas for dual vacuum circuit |

| Load movement | Tilting system 0–90° 90° frame rotation for vertical installation |

| Operating system | DC vacuum pump powered from on-board batteries High capacity rechargeable batteries with battery level indicator Battery charger included, economizer for reduction of energy consumption Quick change battery pack |

| Vacuum system | 2 independent vacuum circuits, each with vacuum reserve and non-return valve |

| Weight of lifter | 61 kg |

| Control | Manual ON/OFF valve for load suction and release Release of the load by dual action security command Radio remote control for suction and release (optional) |

| Standard features | Audible and visual low vacuum warning devices Vacuum gauge for each vacuum circuit, vacuum filter Battery charger 240 Volt Removable suspension to reduce the height below the hook |

Available models:

| Model | Capacity (kg) | No. of Pads | Suction and Release Control |

|---|---|---|---|

| CLW-M | 375 | 1 | Manual |

| CL-W | 375 | 1 | Radio Remote Control |

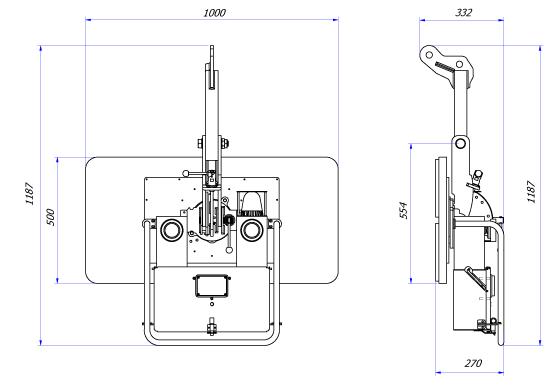

Technical drawings for vertical wall panels

.jpeg) |

.jpeg) |

|

With suspension |

Without suspension |

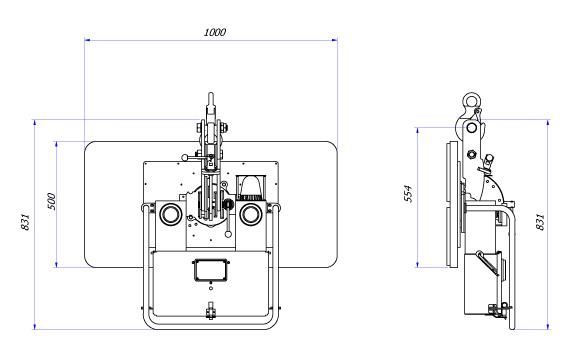

Technical drawings for horizontal wall panels

|

|

|

With suspension |

Without suspension |

Serie CL 1-4

CL1-4 is the vacuum lifter specific for handling and installing insulated panels

Due to its modular frame, it can be adapted to install both wall and roof panels.

It is equipped with four suction pads with a maximum capacity of 250 kg. The tilting system enables safe vertical movement of horizontally-positioned sandwich panels. Its modular and flexible design allows it to lift various panel types, including flat, micro-rib, and trapezoidal panels, made from mineral wool or polyurethane. Additionally, the CL1-4 can be customized to handle special panels such as roof tile-shaped or other uniquely profiled panels. To optimize storage and transport, the lifter includes a convenient parking stand for forklifts, equipped with a protective cover. The structure of the lifter can be disassembled and stored inside the stand, reducing its dimensions to just 100x80x145 cm and minimizing space during transportation.

Specifications:

- Tilt system 0-90°

- Dual vacuum circuit built to EN13155 standard

- Radio remote control (optional)

- Modular frame

- Safety systems

- Parking stand for forklift

Accessories included:

Parking stand for forklift

Forklift-sized parking stand for easy storage and transport. Protective cover included.

Specific pads for panels

Specially designed seals to ensure grip on different panel types (smooth, trapezoidal, micro-ribbed).

Support for assembled vacuum lifter

Steel base to support the assembled vacuum lifter without damaging the pads when not in use.

Tilt assistant bracket

Practical metal tilt assistant attachment for easier vertical positioning.

Spare battery kit

Additional kit of high-capacity batteries to easily replace the low ones without interrupting your job.

External charger

External charger to always have the spare batteries kit in charge.

Optional accessories:

- Remote control

- Extension arms

- Special pads

- Additional alarm

| Application | Installation of insulated roofing and wall panels horizontally and vertically Smooth, micro-rib and trapezoidal panels |

|---|---|

| Capacity | Max 400 kg |

| Suction pads | 6 vacuum pads (800×120 mm) Special fast-replacement gaskets |

| Load movement | Tilt system 0–90° 90° frame rotation for vertical installation |

| Operating system | DC vacuum pump powered from on-board batteries High capacity rechargeable batteries with battery level indicator Battery charger included Quick change battery pack |

| Vacuum system | 2 independent vacuum circuits, each with vacuum reserve and non-return valve |

| Weight of lifter | Depends on configurations |

| Control | Manual ON/OFF valve for load suction and release Release of the load by dual action security command Radio remote control for load suction and release (optional) |

| Standard features | Audible and visual low vacuum warning devices Vacuum gauge for each vacuum circuit, vacuum filter Battery charger 240 Volt Lockable vertical and horizontal tilting |

Available models:

| Capacity (kg) | N. pads | Suction and release | Extension up to 4m | Extension up to 6.5m |

|---|---|---|---|---|

| 400 | 6 | Manual | CL1-6 | CL1-6 EXT |

| 400 | 6 | Radio remote control | CL1-6 RC | CL1-6 EXT RC |

Serie CL 1-6

CL1-6 vacuum lifter for handling and installing insulated panels

Due to its modular frame, it can be adapted to install both wall and roof panels.

CL1-6 is equipped with 6 suction pads with a maximum capacity of 400kg. The tilting system makes it possible to safely move the horizontally-resting sandwich panels by tilting them vertically. The modularity and flexibility of CL1-6 also apply to the type of panels it can lift, including flat, micro-rib and trapezoidal, either in mineral wool or in polyurethane. In addition to this, CL1-6 can also be customized to lift special panels, such as roof tile shaped and other special profile panels. To optimize space during storage and transportation, the vacuum lifter comes with the handy parking stand for forklift equipped with a protective cover. The structure of the lifter can be disassembled and stored inside the stand, which measures only 100x80x145 cm, to minimize its volume during the transport.

Specifications:

- Tilt system 0–90°

- Dual vacuum circuit built to EN13155 standard

- Radio remote control (optional)

- Modular frame

- Safety systems

- Parking stand for forklift

Accessories included:

Parking stand for forklift

Forklift-sized parking stand for easy storage and transport. Protective cover included.

Specific pads for panels

Specially designed seals to ensure grip on different panel types (smooth, trapezoidal, micro-ribbed).

Support for assembled vacuum lifter

Steel base to support the assembled vacuum lifter without damaging the pads when not in use.

Tilt assistant bracket

Practical metal tilt assistant attachment for easier vertical positioning.

Spare battery kit

Additional kit of high-capacity batteries to easily replace the low ones without interrupting your job.

External charger

External charger to always have the spare batteries kit in charge.

Optional accessories:

- Remote control

- Extension arms

- Special pads

- Additional alarm

| Application | Installation of insulated roofing and wall panels horizontally and vertically Smooth, micro-rib and trapezoidal panels |

|---|---|

| Capacity | Max 400 kg |

| Suction pads | 6 vacuum pads (800×120 mm) Special fast-replacement gaskets |

| Load movement | Tilt system 0–90° 90° frame rotation for vertical installation |

| Operating system | DC vacuum pump powered from on-board batteries High capacity rechargeable batteries with battery level indicator Battery charger included Quick change battery pack |

| Vacuum system | 2 independent vacuum circuits, each with vacuum reserve and non-return valve |

| Weight of lifter | Depends on configurations |

| Control | Manual ON/OFF valve for load suction and release Release of the load by dual action security command Radio remote control for load suction and release (optional) |

| Standard features | Audible and visual low vacuum warning devices Vacuum gauge for each vacuum circuit, vacuum filter Battery charger 240 Volt Lockable vertical and horizontal tilting |

Available models:

| Capacity (kg) | N. pads | Suction and release | Extension up to 4m | Extension up to 6.5m |

|---|---|---|---|---|

| 400 | 6 | Manual | CL1-6 | CL1-6 EXT |

| 400 | 6 | Radio remote control | CL1-6 RC | CL1-6 EXT RC |

Series CLF4

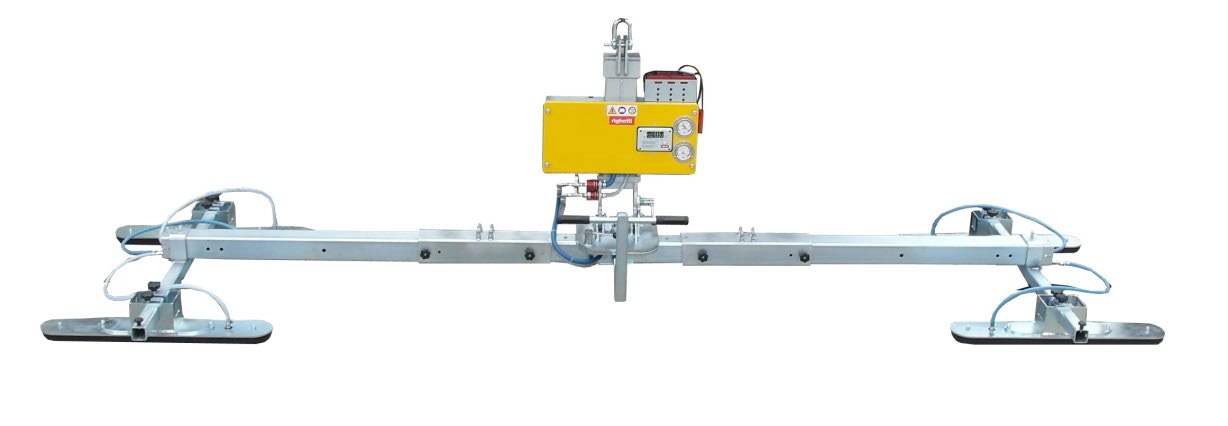

CLF4 vacuum lifter for sandwich roof panels installation

It is equipped with 4 suction pads (800 × 120 mm), resulting in a maximum lifting capacity of 350 kg.

CLF4 can lift different types of sandwich roof panels, including smooth, micronervated, and corrugated, either in mineral wool or polyurethane. In addition, CLF4 can also be customized to lift special panels such as roof-tile effect ones.

The frame of this lifter is fixed horizontally, and the central beam can be 2000 mm, 3000 mm, or 4000 mm long. CLF4 is equipped with a dual vacuum circuit to operate on construction sites in full compliance with EN13155.

Specification:

- Dual vacuum circuit as per EN13155

- Radio remote control (optional)

- Fast-replacement batteries

- Safety devices

| Application | Sandwich roof panels installation |

|---|---|

| Lifting capacity | Max 350 kg |

| Suction pads | 4 suction pads (800 × 120 mm) with special gaskets for fast replacement |

| Load movement | Horizontal movement of the panel |

| Power supply | DC vacuum pump powered from on-board batteries High capacity re-chargeable batteries with level indicator Battery charger included |

| Vacuum system | 2 independent vacuum circuits, each with vacuum reserve and non-return valve |

| Weight of the lifter | Depends on configuration |

| Control | Manual ON/OFF valve for load suction and release Release of the load by dual action security command Radio remote control for load suction and release (optional) |

| Technical features | Audible and visual low vacuum warning devices Vacuum gauge for each vacuum circuit Dual vacuum reservoir Battery charger 240 Volt |

Available models:

| Model | Capacity (kg) | No. of pads | Central beam (mm) | Max panel length (*) |

|---|---|---|---|---|

| CLF4-2000 | 350 | 4 | 2000 | Up to 6/7 m |

| CLF4-3000 | 350 | 4 | 3000 | Up to 9 m |

| CLF4-4000 | 350 | 4 | 4000 | Up to 12 m |

*Max panel length is approximate, depending on the texture of the panel itself.