Why is it worth investing in a manipulator? The difference between cost and value

In the industrial world, investing in the right lifting and load-handling tools is crucial. Industrial manipulators—though initially perceived as a significant expense—offer unmatched value that far outweighs the purchase cost. THEMA, a company with years of experience in this field, specializes in crafting custom solutions designed with ergonomics and human health in mind. Understanding the process of building such a personalized manipulator helps appreciate its true value, translating into long-term benefits for the business.

What is an industrial manipulator and why is it a valuable investment?

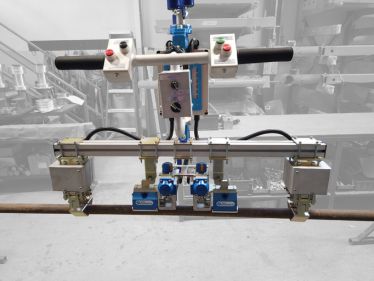

An industrial manipulator is a mechanical arm designed to move objects or products in virtually any direction within a defined workspace. THEMA manipulators are manually operated devices without automatic support. They can be powered by electricity, hydraulics, or pneumatics.

For low‑ to medium‑volume production or assembly lines, a manually operated manipulator offers many advantages:

- Operator safety.

- Reduced labor effort – a single person can perform the work of two or more, cutting labor costs.

- Any operator can perform the task, regardless of physical strength.

- Improved operator ergonomics – minimizes the risk of musculoskeletal disorders.

- Simple maintenance and long‑term reliability thanks to straightforward operating technology.

- Precise movements reduce the risk of product damage.

- Easy access to hard‑to‑reach or hazardous areas without effort, risk, or injury.

Contrary to robots, which often require a precisely defined workspace and significant modifications to existing workstations, a THEMA industrial manipulator can be fully customized to suit your current production environment. This flexibility is especially valuable when part dimensions or workstation layouts change—if you were using robots, such changes would likely necessitate large investments. Robots are best suited for applications with very high cycle rates (e.g., 5–8 s per cycle) and high volume, while manipulators are ideal for repetitive lifting tasks where flexibility and operator adaptation matter most.

Understanding why investing in a THEMA manipulator pays off requires a deep dive into the complex process of designing and customizing each unit. This very process is what adds tremendous value to the final product—turning it into a solution, not just a machine.

The production process at THEMA begins with customer contact and is divided into several stages:

1. On-site Inspection

On-site inspection is the first stage of the production process after initial client contact. Where necessary, it is conducted to assess the area intended for manipulator use and determine the most effective solution. This step is essential for transferring and discussing detailed specifications. It allows a thorough analysis of the specific work area and tasks the manipulator will perform.

2. Design

In the technical office, a layout is developed with 3D simulations of the machine, covering all product handling phases. The aim is to determine both the machine type and the most appropriate type of gripping tool. This detailed design stage is crucial to ensure the manipulator is “tailored” to the existing workspace, avoiding the need for costly redesigns of the entire workstation.

3. Production

After discussing proposed solutions with the client, the machine is built following a precise production process. The gripper tool is crafted by experienced personnel. All components are coded, and each production batch is recorded, ensuring full traceability. The production phase consists of four main stages: steel cutting and welding, painting, assembly, and pneumatic installation.

4. Pre-assembly

Pre-assembly is a key stage in THEMA’s manipulator production process. The machine is initially assembled on a special frame called “0”. This rigorous process allows for detailed verification that all components comply with ISO quality standards. The aim is to detect and eliminate any potential inconsistencies early, which is fundamental to the durability and reliability of the final product.

5. Painting

After the completion of kinetic tests, the machine is prepared for painting. This includes checking finishes and color variants defined in the order. The rigorous surface preparation and painting process involves degreasing, washing, drying, applying one layer of two-component epoxy primer, followed by two layers of two-component polyurethane paint with a minimum thickness of 100 microns.

6. Pneumatic Wiring

After painting, the machine moves to a specialized department where it will be pneumatically wired following the diagrams relating to the project and the order. This step is crucial because THEMA's pneumatic manipulators offer many advantages, such as no electric cables, no electrical hazards, explosion resistance (ATEX certified), simple control, low maintenance, and easy spare part replacement from local suppliers.

7. Inspection and Testing

The final phase includes meticulous and detailed inspection of all manipulator components and all functions controlled by the pneumatic system. In the test room, the product is operated in a simulation of the target area, replicating the client's environment as closely as possible.

The difference between cost and value in investing in a THEMA manipulator

The initial purchase price of a manipulator is only part of the picture. Its real value becomes evident through long-term benefits and savings.

- Ergonomics & Employee Well‑Being

Manipulators minimize the risk of musculoskeletal injuries, reducing sick leave and boosting workplace morale. Investing in employee health is an investment in human capital and long‑term productivity. The “Zero Gravity” concept ensures operators feel virtually no weight after load balancing, enabling fast, precise movements with minimal strain. Balancing systems—such as pressure regulators, payload pre‑selection, triple compensation, or proportional weight valves—customize the manipulator to varying needs, enhancing flexibility and throughput. - Customization & Flexibility

THEMA builds manipulators to fit existing workspaces, eliminating the need for costly station overhauls often required for robots. With options like column‑, ceiling‑, or crane‑mounted models, the solution is optimized for your specific layout and can serve multiple stations. In short: the manipulator adapts to your production, not vice versa. - Operational Safety

Safety features—such as built‑in air reservoirs for safe load descent if power fails, safety valves, anti‑drift brakes, and fail‑safes—minimize accident risk. This protects people and prevents costly downtime, equipment damage, and legal liabilities. - Low Maintenance & Reliability

THEMA’s pneumatic manipulators are virtually maintenance‑free when supplied with clean, dry air. They require far less upkeep than hydraulic systems, resulting in lower operating costs and longer service life. Durability translates directly into savings. - Production Optimization

Effortless handling of heavy, awkward loads reduces fatigue and raises operator productivity. Precise manipulator movements reduce product damage—critical for delicate parts. Task repeatability shortens cycle times and boosts throughput. - Expert Support & Knowledge

Our extensive experience solving complex lifting challenges means customers gain not just a product, but a proven solution. From consultancy to installation and training, we support the entire implementation process—ensuring optimal performance. Accurate payload information is key: over‑specifying capacity makes the manipulator harder to control; we focus on perfectly tailored designs for peak efficiency.

Investing in a THEMA industrial manipulator is far more than a one‑time expense. It’s a strategic decision that delivers significant added value in the form of enhanced safety, improved workplace ergonomics, increased productivity, reduced operating costs, and long‑term reliability. Thanks to our detailed in‑house design and manufacturing process, each manipulator is a truly customized solution, perfectly tailored to the client’s specific needs and work environment. This precision and attention to detail are what set a THEMA manipulator investment apart, making it a worthwhile choice for any forward‑thinking business.

Customized approach to every client

We understand that every company has unique challenges related to load handling. That's why we offer tailored solutions based on a thorough analysis of specifications and requirements.