Case study - Area grippers are the key to reducing downtime | Safe and reliable feeding of chipboard

Handling wooden panels in the furniture industry is a tricky business. A variety of formats, different surface coatings and a dusty production environment place high demands on gripper systems. In a modernised feeding system at furniture manufacturer BMG, FIPA area grippers from the FSG series make a significant contribution to reducing downtimes.

BMG Möbel GmbH & Co. KG is a leading Germancompany in the furniture manufacturing and wholesale sector. The company specialises in the production and sale of customised office and home furniture. High-quality finish foils and robust melamine coatings enable a variety of designs. The range extends from natural wood looks to modern, glossy surfaces.

A 20-year-old feeding system at the plant was causing high downtimes of 20 to 25 per cent. Its task is to feed a double-sided edging system with chipboard. The boards are coated with PVC film and have different formats. Some of them are up to 2 metres long, 22 mm thick and weigh up to 10 kg. This also includes narrow, short and thick workpieces.

The system often had to be repaired and the costs for spare parts, such as vacuum cups, increased significantly. The vacuum was no longer maintained for long. Workpieces were frequently falling off, which disrupted operations, caused a high level of waste and was also dangerous.

Manuel Wischmeyer, Technical Manager at BMG, explains the situation: "Due to this untenable situation, we thought about how we could modernise the system. We improved the hydraulics in-house and changed the suction paths. In the search for a suitable solution for the suction traverse, we came across the FIPA area grippers.”

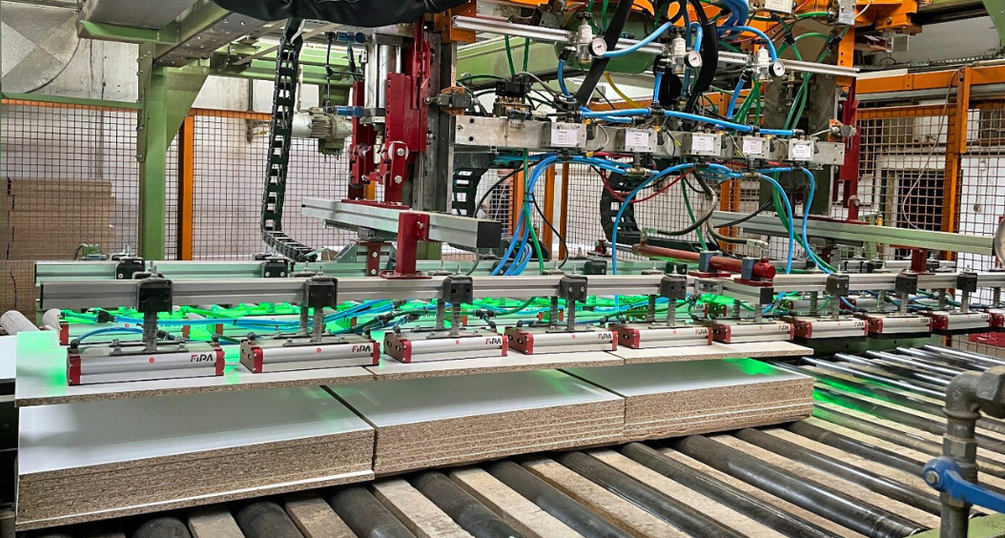

In collaboration with the FIPA field service, the decision was made in favour of two rows of ten area grippers each for handling individual chipboard panels with different dimensions. The wooden parts are picked up reliably even if the exact position of the part to be gripped is not clearly defined. As the system is located in a dusty environment close to an old HOLZMA saw, the sealing foam of the vacuum cups has to be cleaned and replaced regularly. This is very easy with the FIPA area grippers from the FSG series, as the sealing foam can be replaced quickly, without leaving any damage or residue.

Manuel Wischmeyer is delighted with the new solution: "After the modernisation, there are hardly any faults. Downtimes have been reduced to less than 5 per cent. A further reduction is hardly possible due to the complexity of the workpieces. We are more than satisfied with the solution."