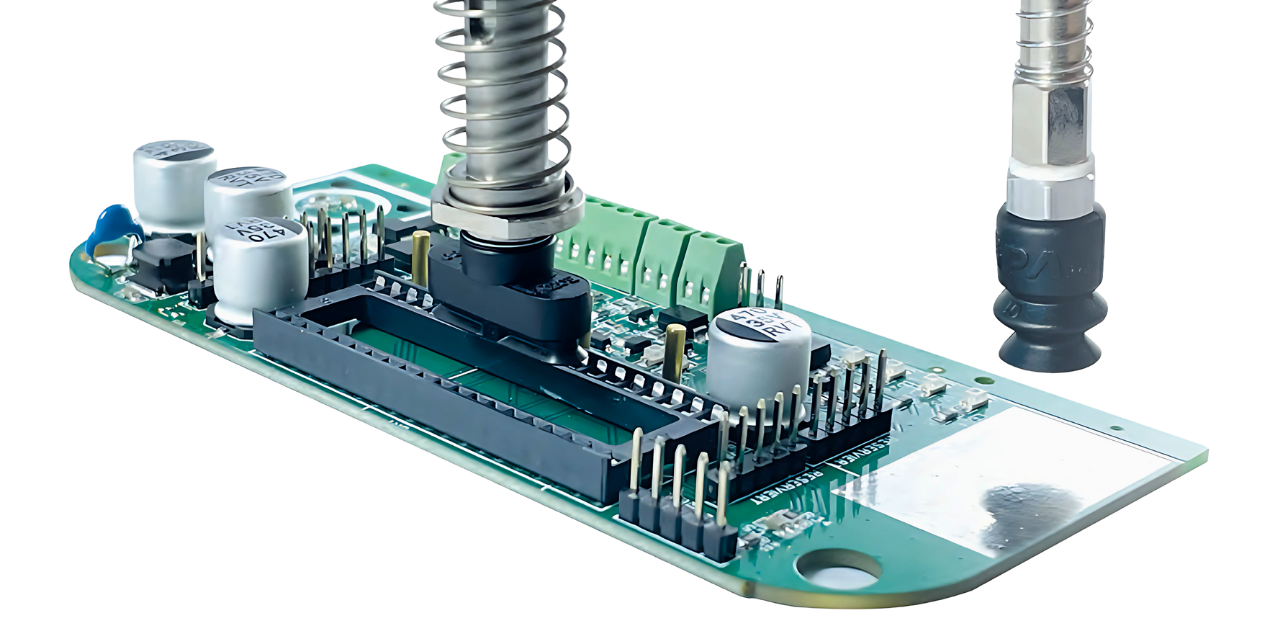

Safety first: New antistatic vacuum cups for damage-free handling of electronic components

Antistatic Vacuum Cups FIPA

In our product range, FIPA offers flat, bellows, and oval vacuum cups made of conductive silicone or NBR.

The electrically conductive materials of the body and sealing lip effectively protect against electrostatic discharges (ESD), which can cause irreversible damage to electronic components. ESD is one of the most common causes of failure, especially in semiconductor integrated circuits.

ESD-protected handling is essential in many high-tech industries. This includes, among others:

- Automotive industry

- Manufacturers of electronic components

- PCB assembly

- Automation of material flow and handling processes in semiconductor factories

- Mechanical engineering

Specialized service providers in contract manufacturing in the electronics industry (Electronic Manufacturing Services – EMS) also rely on protecting sensitive components from electrostatic discharges to prevent malfunction or failure and ultimately ensure the highest product quality.

"We are pleased that our customers can now work completely safely when handling sensitive electronic components" – says Oliver Richter, Product Manager at FIPA.

FIPA's antistatic vacuum cups are made of high-resistance conductive silicone or NBR, which dissipate electrostatic charges in a controlled and safe manner, i.e. a sudden current flow between two objects on the workpiece.

FIPA offers vacuum cups in various variants:

Flat Vacuum Cups

(Ø 0.7–15 mm):

- They ensure high positioning accuracy when placing the component

- They enable fast production cycles and high process repeatability

Vacuum Cups with 1.5-Fold Bellows

(Ø 6–16.5 mm):

- They compensate for differences in height and angles

- They are ideally suited for the gentle placement of components and for gripping elements with curved shapes

Oval Vacuum Cups

(from 4 x 2 mm to 30 x 8 mm):

- The slim design provides maximum holding force with minimal workspace requirements

- They are mainly used for narrow components or limited gripping surfaces

The antistatic vacuum cups are suitable for handling:

- Printed circuit boards

- Electronic components

- Sensitive elements in the field of electromobility

- Gripping plastic parts

- Mounting sensors and control units

Antistatic vacuum cups are also effective for handling display glass and battery components.

More information can be found in the FIPA catalog “Antistatic Vacuum Cups”

FIPA Antistatic Vacuum Cups – Key Features:

- Reliable ESD protection: Conductive materials, such as silicone or NBR, protect electronic components from damage.

- Flexible application: Different designs tailored to various applications.

- Fast production cycles: Flat vacuum cups provide high dynamic performance and excellent repeatability.

- Adaptability: Bellows vacuum cups compensate for differences in height and tilt angles.

- Compact design: Oval vacuum cups offer maximum holding force with minimal space requirements.