Case study: Industrial manipulator for panels - handling container components

Container assembly lines require efficient and safe handling of large panels – both glazed (e.g., windows, doors) and non-glazed. The task involves lifting panels from a pallet and precisely mounting them onto the container structure. While seemingly simple, the process demands high accuracy and significant physical effort from the operator. For this reason, the company decided to implement a specialized pneumatic manipulator.

Previous panel handling process

The previous approach relied on manual handling of the panels, which posed risks of damage, injury, and considerable time loss. Each lift required significant physical strength and focus from the operator, resulting in low efficiency and operator fatigue.

Main operational challenges:

1. Safe lifting without the risk of damage

Ensuring full control over panel movement to avoid impacts, scratches, and accidental collisions with the container structure or surrounding equipment.

2. Handling large and heavy panels

Transporting panels of substantial weight and size requires a stable grip and precise maneuvering, which was difficult and risky when done manually.

3. Accurate positioning inside the container

Precise placement of panels in the designated position is a crucial step affecting the quality of assembly – especially with glazed components like windows and doors.

4. Cycle time optimization and downtime reduction

An overly time-consuming and inconsistent handling process slowed down production and increased the risk of errors, leading to unplanned downtime.

5. Reducing physical strain on the operator

Working with heavy panels involved intense physical effort, affecting comfort, safety, and the long-term performance of personnel.

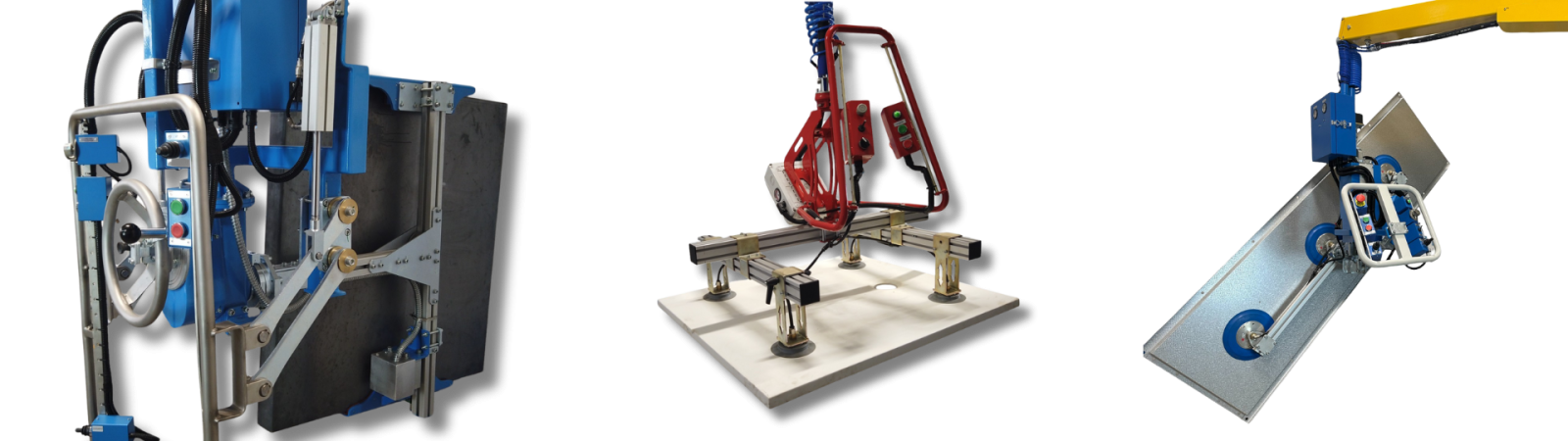

Implementation of the pneumatic manipulator for panel handling

In response to the identified operational challenges, a modern pneumatic manipulator was designed and implemented. Its construction was fully tailored to the specific demands of the container assembly environment. The device is mounted on a custom-designed rail-mounted overhead structure, allowing for a wide range of movement and precise control, even when handling large panels.

Its purpose is not only to transport heavy components but also to relieve the operator, ensure workplace safety, and accelerate the production cycle.

Key features of the solution:

Swing-free operation

Thanks to an advanced motion control system, the manipulator eliminates load swinging. Smooth and stable movement increases safety and allows for precise positioning of panels at the designated mounting points.

Ergonomic design

The device is equipped with adjustable handles that can be adapted to the operator’s height and preferences, along with a system for smooth lifting and lowering. This allows the operator to maintain full control over the load without applying excessive physical force.

Customizability

The manipulator was designed with versatility in mind. It can handle panels of various dimensions, thicknesses, and weights. Its gripping system can be adapted to specific surface types – including glazed components – making it a universal tool for different assembly lines and industries.

Safety mechanisms

The built-in load locking system protects panels from accidental dropping in the event of sudden work stoppage or operator error. Additionally, the pneumatic system is equipped with automatic force compensation and emergency mechanisms that ensure safety in all operating conditions.

Enhanced safety

The manipulator significantly reduces the risk of workplace accidents. Integrated safety systems, precise load handling, and the elimination of manual lifting minimize the chances of collisions, overexertion, and injuries. Operators work in more predictable and controlled conditions, which translates into an overall improvement in occupational safety standards at the facility.

Increased efficiency

Thanks to intuitive controls and the ability to adapt to various panel formats, the time required for each operation has been reduced. Fewer positioning errors and faster system response contribute to smoother workflows and, consequently, higher overall productivity on the assembly line.

Operator comfort

The manipulator’s design was created with the user in mind. Simple, intuitive controls, reduced lifting resistance, and the ability to work in a comfortable posture help significantly reduce physical strain. Operators can focus on precise panel positioning without excessive physical effort — a critical factor during long shifts.

Detailed device design

The project included the development of detailed technical drawings of the machine, taking into account the spatial parameters of the facility and the ergonomic requirements of the operators.

.jpg)

The manipulator was integrated with a dedicated overhead rail structure, which was specifically designed and built for this workstation. This solution allows for smooth movement of the device along the panel assembly area.

Implementation results – final testing and performance evaluation

The pneumatic manipulator was designed from the outset with the specific needs of container assembly workstations in mind. During final testing, the device proved its functionality and suitability for operational requirements – both in terms of ergonomics and efficiency. Integrated with a newly developed rail-mounted structure, the manipulator can move along the entire working area, giving operators full flexibility in handling large panels, regardless of type – glazed (e.g., windows, doors) or non-glazed. Precise control, tilt capability, and stable load guidance greatly simplify the positioning of each panel on the container structure.

Testing revealed a noticeable improvement in operator comfort – handling the device required no physical exertion, and all actions could be carried out smoothly, predictably, and consistently.

Key outcomes:

1. Elimination of manual lifting of heavy panels

2. Reduced physical strain on personnel

3. Increased speed and precision of assembly

4. Improved overall safety and process ergonomics

The implemented solution not only streamlined the execution of production tasks but also had a positive impact on the comfort of the entire assembly team.

Wondering if a similar manipulator would work in your facility? Talk to our specialist – together we’ll find the best solution.