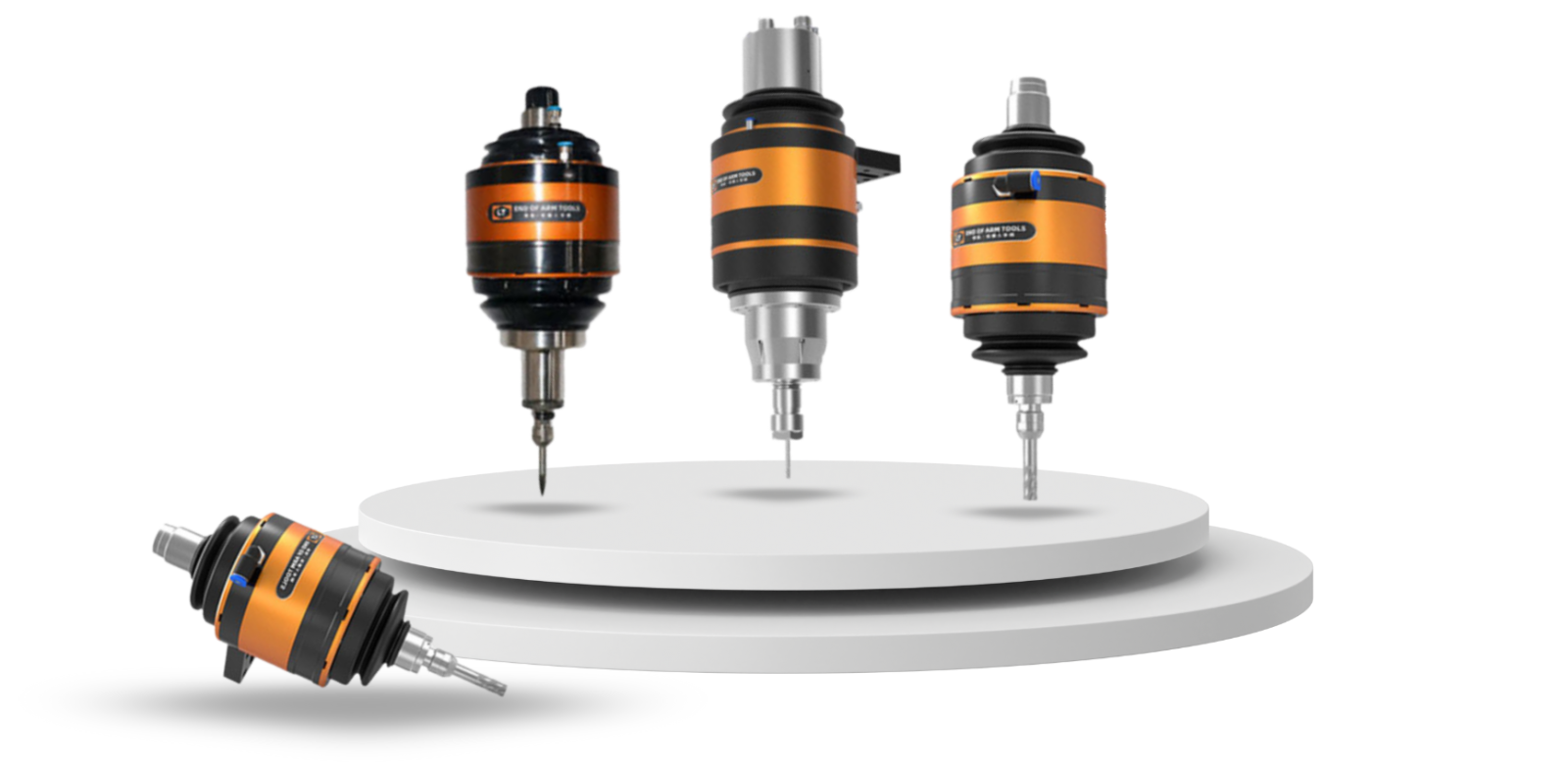

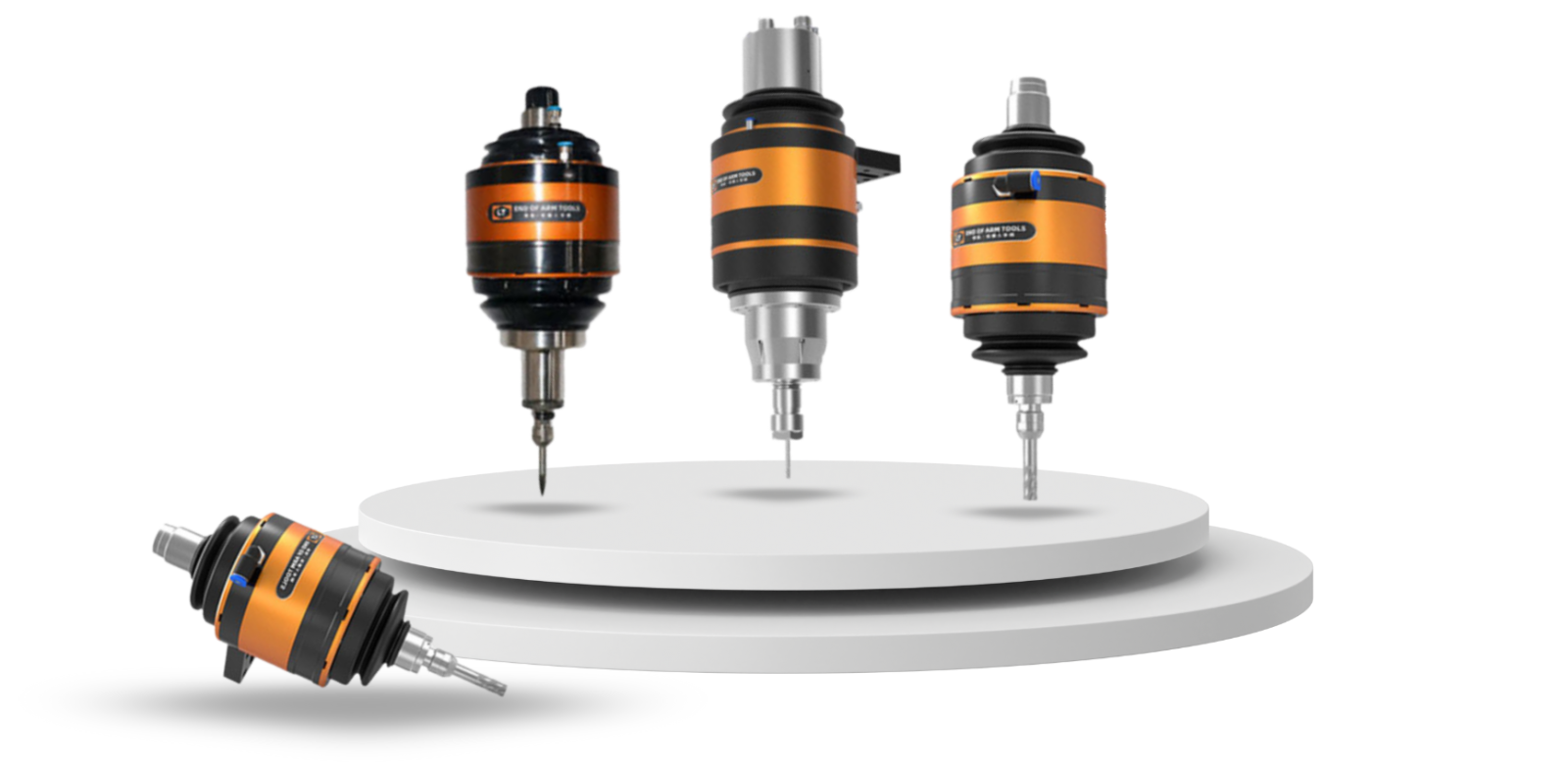

LH-TC Floating grinding spindle

Table

The force-controlled floating material removable tool is an efficient and flexible automatic deburring tool, equipped with a powerful electric motor, it can quickly and automatically remove burrs, seams and flash edges from various materials, used in multi-process, suitable for cast iron, steel, aluminum alloy, plastic and other materials.

Specification:

360 , floating angle +/-5-degree, the max floating distance in axial direction is 12mm;

Accurate absorption of workpiece error, high precision, good deburring effect, good finish;

The maximum speed of the electric spindle is 60,000rpm, flexible contact, and the speed is controllable;

The pressure force between the tool and the workpiece can be adjusted.

Using compressed air for floating adjustment:

The floating mechanism has an air chamber that provides floating power, and the size of the floating power can be adjusted by adjusting the pressure of the air chamber.

When the floating pressure does not change, the floating force remains unchanged within the floating range.

The control of floating is an important factor to ensure uniform cutting.

|

.png)

Stable operation

Stable speed, stable torque, stable dynamic balance.

|

.png)

Ceramic bearings

Ceramic bearings have twice the durability and longer life than steel bearings.

|

.png)

Signal feedback

The speed can be read and controlled in real time through the controller.

|

.png)

High precision, large torque, low noise

The spindle runout accuracy is less than 1 μm, the best choice for high-precision machining.

|

|

.png)

General Interface

General interface for various systems.

|

Strong bearing capacity

Special shell, greatly increase the bearing capacity of the motorized spindle.

|

.png)

Perfect cooling system

Air cooling, water cooling, oil cooling.

|

Good sealing effect

V-type sealing ring and rubber protective sleeve double protection, can block a lot of dust.

|

Use Scope:

Most magnesium & aluminum alloy, zinc alloy die casting parts;

Steel stamping parts;

Composite Material, Mold closing line after plastic casting, flash;

Machined burrs, raw edges.

Model selection:

1. Select the spindle floating type according to the deburring process: radial or axial.

2. Choose the spindle diameter and whether to change the cutter according to the use and application.

3. Select spindle speed and power according to the material to be polished.

4. Select the specific spindle model according to the burr size.

5. Select the appropriate bending moment and torque according to the robot load recommendations.

6. Choose the right cutter according to the grinding material.

7. Select other accessories as needed, such as: water cooler, holder.

LT-FR020A-20-S6000

Table

.png)

Light weight design, low noise, exquisitely grinding

Position repeatability, eliminate the workpiece shape error perfectly

Adjustable applied force between cutter and workpiece

Flexible contact between cutter and workpiece to avoid over cutting

Replaceable standard industrial grinding heads

Supports automatic tool change

Standard configuration:

6m cables

Controller 1 set

Precision pressure regulating filter 1 piece

Precision pressure regulate valve 2 pieces

Clamping: Φ3.0mm (CHA-3.0) / Screw nut (CHN-A)

Wrench (8×5) 1 piece, (9×11) 1 piece

Use scope:

Aluminum alloy, resin etc.

Processed flanging

Seam line

Chamfer below C0.5

General burrs

Technical Data

| Technical Data |

| Model |

LT-FR020A-20-S6000 |

| Autorotation Rate |

60000 rpm |

| Power |

250 W |

| Floating Angle (X, Y) |

±5° |

| Radial Floating Angle |

360° |

| Axial Compliance |

4 mm |

| Floating Moment |

3.3N - 13.6N |

| Chatter |

1μm |

| Diameter of Floating Air Pipes |

Φ4 mm |

| Diameter of Spindle Air Pipes |

Φ6 mm |

| Air Pressure Adjustable Range |

0.1 - 0.4 Mpa |

| Dimensions |

Φ68 mm * 195 mm |

| Weight |

1051 g |

LT-FRC030B-3060

Table

360° Radial floating, adaptive all-round deburring

Highly efficient in multi-process deburring applications

Flexible contact between cutter and workpiece to avoid overcutting

Adjustable applied force between cutter and workpiece

Replaceable standard industrial grinding heads

Supports automatic tool change

Standard configuration:

8m cables

Controller 1 set

Precision pressure regulating valve 1 piece

Proportional valve 1 piece

Precision pressure regulating filter 1 piece

Clamping: Φ6.0mm (CHK-6.0) / Screw nut (K-265)

Optional clamping Φ3.0mm (CHK-3.0) / Screw nut (K-265)

Wrench (12x14) 2 pieces, (22x27) 2 pieces

Use scope:

Cast iron, steel, aluminum alloy, resin etc.

Seam line

Connection part below 2mm

Processed flanging

Chamfer below C2

General burrs

Technical Data

| Technical Data |

| Model |

LT-FRC030A-3060 |

| Autorotation Rate |

60000 rpm |

| Power |

350 W |

| Floating Angle (X, Y) |

±5° |

| Radial Floating Angle |

360° |

| Axial Compliance |

7 mm |

| Floating Moment |

7.2N - 28.8N |

| Chatter |

1μm |

| Diameter of Floating Air Pipes |

Φ4 mm |

| Diameter of Spindle Air Pipes |

Φ6 mm |

| Air Pressure Adjustable Range |

0.1 - 0.4 Mpa |

| Dimensions |

Φ104 mm x 270 mm |

| Weight |

3482.3 g |

| Automatic Tool Change Capability Diameter |

0.5 - 6.35 mm |

LT-FRC030B-3030T

Table

The torque is greatly increased and the power is more sufficient

.png)

360° Radial floating, adaptive all-round deburring

Highly efficient in multi-process deburring applications

Flexible contact between cutter and workpiece to avoid overcutting

Adjustable applied force between cutter and workpiece

Replaceable standard industrial grinding heads

Supports automatic tool change

Standard configuration:

8m cables

Controller 1 set

Precision pressure regulating valve 1 piece

Proportional valve 1 piece

Precision pressure regulating filter 1 piece

Clamping: Φ6.0mm (CHK-6.0) / Screw nut (K-265)

Optional clamping Φ3.0mm (CHK-3.0) / Screw nut (K-265)

Wrench (12x14) 2 pieces, (22x27) 2 pieces

Use scope:

Cast iron, steel, aluminum alloy, resin etc.

Seam line

Connection part below 2mm

Processed flanging

Chamfer below C2

General burrs

Technical Data

| Technical Data |

| Model |

LT-FRC030B-3030T |

| Autorotation Rate |

30000 rpm |

| Power |

350 W |

| Floating Angle (X, Y) |

±5° |

| Radial Floating Angle |

360° |

| Axial Compliance |

7 mm |

| Floating Moment |

7.2N - 28.8N |

| Chatter |

1μm |

| Diameter of Floating Air Pipes |

Φ4 mm |

| Diameter of Spindle Air Pipes |

Φ6 mm |

| Air Pressure Adjustable Range |

0.1 - 0.4 Mpa |

| Dimensions |

Φ104 mm x 266 mm |

| Weight |

3497.3 g |

| Change The Knife Automatically Diameter |

0.5 - 6.35 mm |

LT-FR030B-3060

Table

.png)

360° Radial floating, adaptive all-round deburring

Absorb the deformation of the product during the deburring process, enables adaptive processing, reduces debugging difficulty

Ensures repeatable positioning to perfectly eliminate workpiece errors

Maintains flexible contact between cutter and workpiece to prevent over-cutting

Replaceable standard industrial grinding heads

Standard configuration:

8m cables

Controller 1 set

Precision pressure regulating valve, 2 pieces

Precision pressure regulating filter, 1 piece

Clamping: Φ6.0mm (CHK-6.0) / Screw nut (K-265)

Optional clamping Φ3.0mm (CHK-3.0) / Screw nut (K-265)

Wrenches (12x14) 2 pieces, (22x27) 2 pieces

Use scope:

Cast iron, steel, aluminum alloy, resin, etc.

Seam line

Connection parts below 2mm

General burrs

Processed flanging

Chamfer below C2

Technical Data

| Technical Data |

| Model |

LT-FR030B-3060 |

| Autorotation Rate |

60000 rpm |

| Power |

350 W |

| Floating Angle (X, Y) |

±5° |

| Radial Floating Angle |

360° |

| Axial Compliance |

5 mm |

| Floating Moment |

7.2N - 28.8N |

| Chatter |

1μm |

| Diameter of Floating Air Pipes |

Φ4 mm |

| Diameter of Spindle Air Pipes |

Φ6 mm |

| Air Pressure Adjustable Range |

0.1 - 0.4 Mpa |

| Dimensions |

Φ82 mm x 212 mm |

| Weight |

1796.6 g |

| Tool Holding Diameter |

6 mm |

LT-FR030B-3030T

Table

The torque is greatly increased and the power is more sufficient

Ceramic bearings are 2 times more durable than steel bearings

More efficient in hole deburring applications

.png)

360° Radial floating, adaptive all-round deburring

Absorb the deformation of the product during the deburring process, enables adaptive processing, reduces debugging difficulty

Ensures repeatable positioning to perfectly eliminate workpiece errors

Maintains flexible contact between cutter and workpiece to prevent over-cutting

Replaceable standard industrial grinding heads

Standard configuration:

8m cables

Controller 1 set

Precision pressure regulating valve, 2 pieces

Precision pressure regulating filter, 1 piece

Clamping: Φ6.0mm (CHK-6.0) / Screw nut (K-265)

Optional clamping Φ3.0mm (CHK-3.0) / Screw nut (K-265)

Wrenches (12x14) 2 pieces, (22x27) 2 pieces

Use scope:

Cast iron, steel, aluminum alloy, resin, etc.

Seam line

Connection parts below 2mm

General burrs

Processed flanging

Chamfer below C2

Technical Data

| Technical Data |

| Model |

LT-FR030B-3030T |

| Autorotation Rate |

30000 rpm |

| Power |

350 W |

| Floating Angle (X, Y) |

±5° |

| Radial Floating Angle |

360° |

| Axial Compliance |

5 mm |

| Floating Moment |

7.2N - 28.8N |

| Chatter |

1μm |

| Diameter of Floating Air Pipes |

Φ4 mm |

| Diameter of Spindle Air Pipes |

Φ3 mm |

| Air Pressure Adjustable Range |

0.1 - 0.4 Mpa |

| Dimensions |

Φ82 mm x 208 mm |

| Weight |

1815.6 g |

LT-FR040B-S4040

Table

.png)

Cone runout <1.5μm

Available Toolholder diameter from 1mm to 7mm

Air cooling and clamp heat dissipation system ensures normal fuselage temperature

Positive pressure air curtain dust proof system to lengthen service life

Replaceable standard industrial grinding heads

Supports automatic tool change

Standard configuration:

8m cables

Controller 1 set

Precision pressure regulating valve, 2 pieces

Precision pressure regulating filter, 1 piece

Clamping: Φ6.0mm (CHK-6.0) / Screw nut (K-265)

Optional clamping Φ3.0mm (CHK-3.0) / Screw nut (K-265)

Wrenches (12x14) 2 pieces, (22x27) 2 pieces

Use scope:

Cast iron, steel, aluminum alloy, resin, etc.

Seam line

Connection parts below 2mm

General burrs

Processed flanging

Chamfer below C2

Technical Data

| Technical Data |

| Model |

LT-FR040B-S4040 |

| Autorotation Rate |

3000-20000 rpm |

| Power |

400 W |

| Floating Angle (X, Y) |

±5° |

| Radial Floating Angle |

360° |

| Axial Compliance |

6.5 mm |

| Floating Moment |

7.2N - 28.8N |

| Chatter |

1.5μm |

| Diameter of Floating Air Pipes |

Φ4 mm |

| Diameter of Spindle Air Pipes |

Φ6 mm |

| Air Pressure Adjustable Range |

0.1 - 0.4 Mpa |

| Dimensions |

Φ97 mm x 202.7 mm |

| Weight |

3240.4 g |

LT- 6000

Table

.png)

High Speed, Efficiency, Large volume cutting

Over cut prevention, Low residue

Automatically Replaceable cutter, tool holder interface standard: ISO25

Available Tool holder diameter 2-16mm

Standard configuration:

Tool holder

Chuck 10mm

Standard wrench

Use scope:

Cast iron, steel, aluminum alloy, resin, etc.

Seam line

Connection part below 4mm

General burrs

Processed flanging

Chamfer below C4

Technical Data

| Technical Data |

| Model |

LT-6000 |

| Maximum Speed |

36000 rpm |

| Rated Speed |

20000 rpm |

| Rated Power (S1-100%) |

6 KW |

| Rated Current (S1-100%) |

13 A |

| Rated Torque (S1-100%) |

2.8 Nm |

| Voltage |

380 V |

| Spindle Cooling Method |

Water cooling |

| Spindle Air Seal |

Φ6 mm |

| Floating Angle (X, Y) |

±4° |

| Radial and Axial Floating |

Radial 360°, Axial 10 mm |

| Floating Force |

96N - 203.8N |

| Dimensions |

Φ180 mm x 488 mm |

| Weight |

30.7 kg |

| Automatic Tool Change Capability |

Shank diameter 10 mm |

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)