Oval vacuum cups SO

The FIPA oval vacuum cups of the SO series allow automation systems to transport objects of longitudinal shape, f.e. elements with crossbars, wood, components formed from metal and plastics. FIPA oval vacuum cups of a certain width in combination with round vacuum cups of the same diameter, have a much higher gripping force, which is why they are an excellent solution when the working surface of the object being moved is elongated or limited. Oval FIPA bellows vacuum cups allow to take objects with uneven surfaces in a repetitive manner. In addition, in many models, internal ribbing stabilizes the vacuum cup, prevents the deformation of the transferred product, preventing it from sinking into the vacuum cup, additionally the ribbing increases the friction force eliminating the probability of slipping.

FIPA has a wide selection of oval vacuum cups. Various types - resistant to high temperatures, free of wettability reducing substances (PWIS), with and without bellows, elastic made of natural rubber. FIPA covers the entire range of oval vacuum cups with its offer.

Oval flat vacuum cups - SO-E

Small flat vacuum cups in oval design for elongated workpieces where only minimal space is available (e.g. semiconductors, carrier plates, etc.). Connection via an interlocking snap-in plug-in nipple.

Advantages:

> Significantly increased suction force compared to round vacuum cups of the same width

> Optimum bending strength due to elongated carrier plate in the plug-in nipple

> Secured against rotation

> Antistatic version available

> Cost-effective replacement of worn seals

| Item no. | Spare fittings | ||||||

| Model / Lip dimensions | M5-male | M6-male | Deflection [mm] | Material / Colour | Spare cup | M5-male | M6-male |

| SO-E-10x4 | 130.10x4.115._* | 130.10x4.068._* | 0.9 | NBR (sw), SI (tr) | 132.10x4.003._* | 270.463 | 270.339 |

| SO-E-10x5 | 130.10x5.116._* | 130.10x5.071._* | 0.9 | NBR (sw), SI (tr) | 132.10x5.007._* | 270.463 | 270.339 |

| SO-E-10x6 | 130.10x6.117._* | 130.10x6.073._* | 0.9 | NBR (sw), SI (tr) | 132.10x6.011._* | 270.463 | 270.339 |

| SO-E-20x4 | 130.20x4.118._* | 130.20x4.069._* | 0.9 | NBR (sw), SI (tr) | 132.20x4.005._* | 270.464 | 270.340 |

| SO-E-20x5 | 130.20x5.119._* | 130.20x5.081._* | 0.9 | NBR (sw) | 132.20x5.009._* | 270.464 | 270.340 |

| SO-E-20x6 | 130.20x6.120._* | 130.20x6.074._* | 0.9 | NBR (sw), SI (tr) | 132.20x6.013._* | 270.464 | 270.340 |

| SO-E-20x8 | 130.20x8.121._* | 130.20x8.076._* | 0.9 | NBR (sw), SI (tr) | 132.20x8.015._* | 270.464 | 270.340 |

| SO-E-30x5 | 130.30x5.123._* | 130.30x5.072._* | 0.9 | NBR (sw), SI (tr) | 132.30x5.010._* | 270.464 | 270.340 |

| SO-E-30x6 | 130.30x6.124._* | 130.30x6.075._* | 0.9 | NBR (sw), SI (tr) | 132.30x6.014._* | 270.464 | 270.340 |

| SO-E-30x8 | 130.30x8.125._* | 130.30x8.077._* | 0.9 | NBR (sw), SI (tr) | 132.30x8.017._* | 270.464 | 270.340 |

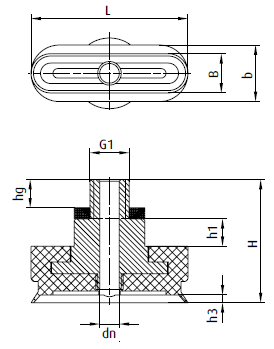

| Item no. | L [mm] | B [mm] | b [mm] | Ø dn [mm] | G1 | H [mm] | h1 [mm] | h3 [mm] | hg [mm] |

| 130.10x4.115._* | 10 | 4,6 | 7 | 2,5 | M5 | 15,5 | 3,5 | 1 | 3,6 |

| 130.10x4.068._* | 10 | 4,6 | 7 | 2 | M6 | 15,5 | 3,5 | 1 | 4 |

| 130.10x5.116._* | 10 | 5 | 7 | 2,5 | M5 | 15,5 | 3,5 | 1 | 3,6 |

| 130.10x5.071._* | 10 | 5 | 7 | 2 | M6 | 15,5 | 3,5 | 1 | 4 |

| 130.10x6.117._* | 10 | 6 | 7 | 2,5 | M5 | 15,5 | 3,5 | 1 | 3,6 |

| 130.10x6.073._* | 10 | 6 | 7 | 2 | M6 | 15,5 | 3,5 | 1 | 4 |

| 130.20x4.118._* | 20 | 4,3 | 7 | 2,5 | M5 | 15,5 | 3,5 | 1 | 3,6 |

| 130.20x4.069._* | 20 | 4,3 | 7 | 2 | M6 | 15,5 | 3,5 | 1 | 4 |

| 130.20x5.119._* | 20 | 5 | 7 | 2,5 | M5 | 15,5 | 3,5 | 1 | 3,6 |

| 130.20x5.081._* | 20 | 5 | 7 | 2 | M6 | 15,5 | 3,5 | 1 | 4 |

| 130.20x6.120._* | 20 | 6 | 7 | 2,5 | M5 | 15,5 | 3,5 | 1 | 3,6 |

| 130.20x6.074._* | 20 | 6 | 7 | 2 | M6 | 15,5 | 3,5 | 1 | 4 |

| 130.20x8.121._* | 20 | 8 | 8 | 2,5 | M5 | 15,5 | 3,5 | 1 | 3,6 |

| 130.20x8.076._* | 20 | 8 | 8 | 2 | M6 | 15,5 | 3,5 | 1 | 4 |

| 130.30x5.123._* | 30 | 5 | 7 | 2,5 | M5 | 15,5 | 3,5 | 1 | 3,6 |

| 130.30x5.072._* | 30 | 5 | 7 | 2 | M6 | 15,5 | 3,5 | 1 | 4 |

| 130.30x6.124._* | 30 | 6 | 7 | 2,5 | M5 | 15,5 | 3,5 | 1 | 3,6 |

| 130.30x6.075._* | 30 | 6 | 7 | 2 | M6 | 15,5 | 3,5 | 1 | 4 |

| 130.30x8.125._* | 30 | 8 | 8 | 2,5 | M5 | 15,5 | 3,5 | 1 | 3,6 |

| 130.30x8.077._* | 30 | 8 | 8 | 2 | M6 | 15,5 | 3,5 | 1 | 4 |

Oval vacuum cups for cylindrical products – SO-Z

Oval vacuum cup for cylindrical products such as pins, needles, tubes, etc. Connection via plug-in nipple, hollow screw (SO-Z-10-18) or direct plug-in to the machine (SO-Z-4-10).

Advantages:

- Significantly greater suction force over normal oval vacuum cups due to three-dimensional oval suction lip contour partially encompassing the workpiece

- Cost-effective replacement of worn seals

| Item no. | Model / Lip dimensions | Suitable for cylindrical products with Ø [mm] | Material / Colour |

| 201.10x3.005._* | SO-Z-2-4 | 2 - 4 | NBR (sw), SI (tr) |

| 201.10x6.006._* | SO-Z-3-7 | 3 - 7.5 | NBR (sw), SI (tr) |

| 132.15x7.073._* | SO-Z-4-10 | 4 - 10 | SI (r) |

| 201.12x9.007._* | SO-Z-6-13 | 6 - 13 | NBR (sw), SI (tr) |

| 9.23x11.036._* | SO-Z-10-18 | 10 - 18 | SI (tr) |

| Suitable fittings | |||

| Item no. | M5-male | G1/8-male | G1/8-female |

| 201.10x3.005._* | 270,300 | -- | -- |

| 201.10x6.006._* | 270,300 | -- | -- |

| 132.15x7.073._* | -- | -- | -- |

| 201.12x9.007._* | 270,300 | -- | -- |

| 9.23x11.036._* | 270,310 | 270,493 | 270,494 |

| Dimensions | |

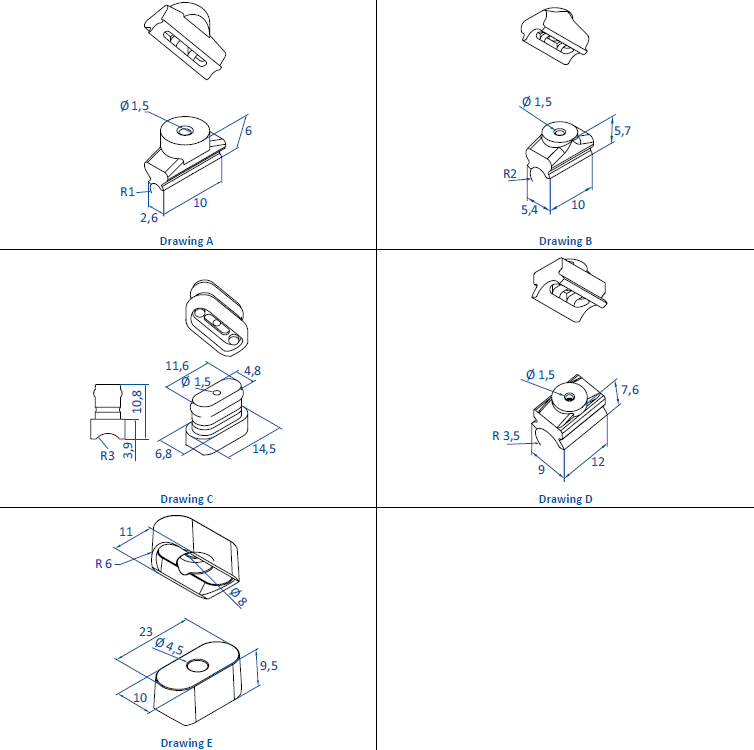

| Item no. | Drawing |

| 201.10x3.005._* | A |

| 201.10x6.006._* | B |

| 132.15x7.073._* | C |

| 201.12x9.007._* | D |

| 9.23x11.036._* | E |

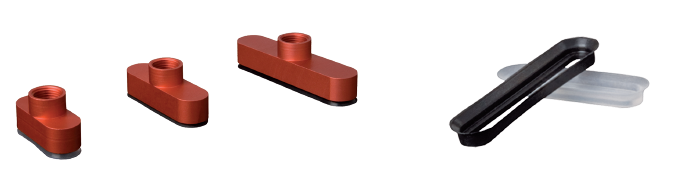

Oval vacuum cups, flat – SO-C

Flat vacuum cups in oval design for elongated workpieces where only minimal space is available (e.g. rails, profiles, tubes, bolts, etc.). Vacuum chamber housing of anodized aluminum. Rubber sealing lip is fixed by a screwed rubber clamping plate.

Advantages:

- Significantly increased suction force compared to round vacuum cups of the same width

- Warp-resistant aluminum housing

- Cost-effective replacement of worn seals

| Item no. | Model | Connection thread | Deflection [mm] | Material / Color | Spare sealing lip |

| 130.30x12.057._* | SO-C-30x12 | G1/8-female | 1 | SI (tr), NR (sw) | 132.30x12.025._* |

| 130.40x12.058._* | SO-C-40x12 | G1/8-female | 1 | SI (tr), NR (sw) | 132.40x12.027._* |

| 130.55x12.082._* | SO-C-55x12 | G1/8-female | 1 | NBR (sw), SI (tr), NR (sw) | 132.55x12.029._* |

| Item no. | L [mm] | B [mm] | Ø d1 [mm] | Ø dn [mm] | G1 | H [mm] | h1 [mm] | h2 [mm] |

| 130.30x12.057._* | 30 | 12 | 12 | 3,5 | G1/8 | 16,5 | 10 | 1,3 |

| 130.40x12.058._* | 40 | 12 | 12 | 3,5 | G1/8 | 16,5 | 10 | 1,4 |

| 130.55x12.082._* | 55 | 12 | 12 | 3,5 | G1/8 | 16,5 | 10 | 1,5 |

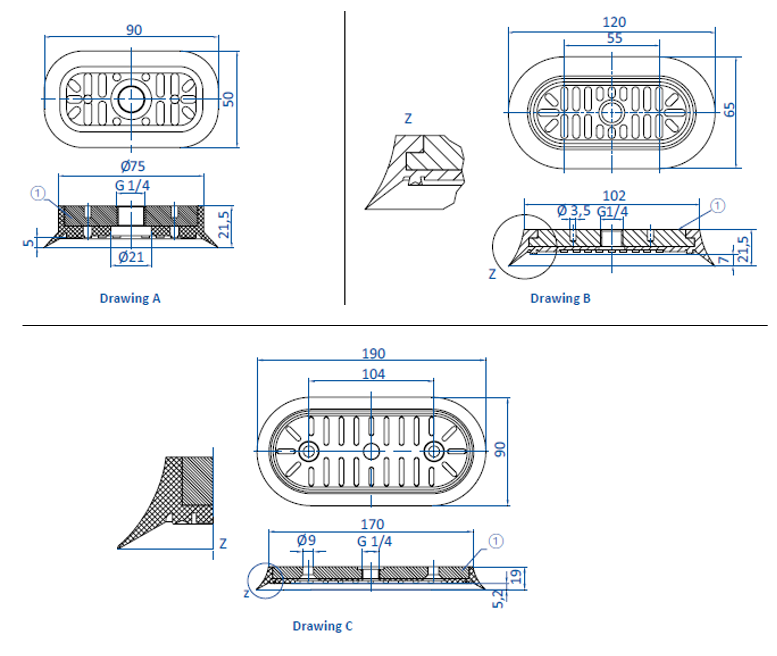

Oval vacuum suction plates for textured surfaces – SOPL-R

Oval vacuum cups for handling both rough surfaces and smooth, markedly uneven products. Connection via vulcanized aluminum plate.

Advantages:

- Leak-free gripping of difficult product surfaces thanks to extremely flexible, thinly tapered sealing lip

- Cleats help prevent warping of the product

- Optimum process reliability due to vulcanized backing plate, as well as additional internal safety sealing lip (190x90 mm and 120x65 mm)

| Item no. | Model / Lip dimensions | Connection thread | Material / Colour | Deflection [mm] | Weight [g] |

| 130.90x50.113._* | SOPL-R-90x50 | G1/4-female | NR (bg) | 5 | 72 |

| 9.120x65.088._* | SOPL-R-120x65 | G1/4-female | NR (bg) | 7 | 131 |

| 9.190x90.061._* | SOPL-R-190x90 | G1/4-female | NR (bg) | 5,5 | 295 |

| Dimensions | |

| Item no. | Drawing |

| 130.90x50.113._* | A |

| 9.120x65.088._* | B |

| 9.190x90.061._* | C |

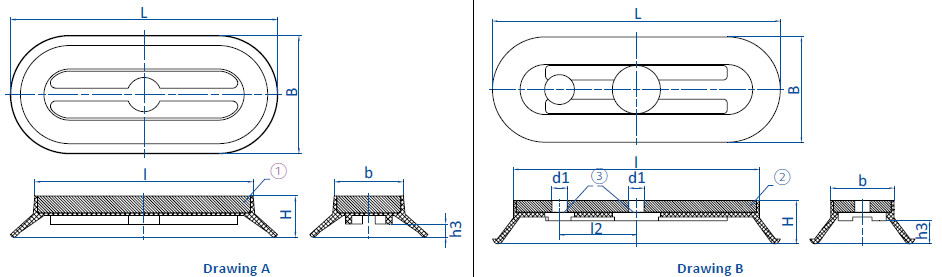

Oval vacuum suction plates – SOPL-S and SOPL-A

Oval vacuum cups, vulcanized, on a carrier plate of steel / aluminum for the handling of long, narrow products such as strips, profiles or frames. Rubberized support surfaces prevent deformation of the product and increase lateral stability.

Advantages:

- High suction force on a small footprint

- Low-marking

- High process reliability due to vulcanized carrier plate

- Individual machine connection possible

| Item no. | Model / Lip dimensions | Material / Colour | Deflection [mm] | Weight [g] | Support surfaces |

| SOPL-S: NBR material, grey, with steel carrier plate | |||||

| 9.200x40.010._* | SOPL-S-200x40 | NBR (gr) | 9 | 140 | lengthwise |

| 9.110x40.009._* | SOPL-S-110x40 | NBR (gr) | 9 | 122 | lengthwise |

| 9.125x55.012._* | SOPL-S-125x55 | NBR (gr) | 9 | 320 | lengthwise |

| 9.150x55.013._* | SOPL-S-150x55 | NBR (gr) | 7 | 255 | lengthwise |

| 9.200x55.014._* | SOPL-S-200x55 | NBR (gr) | 7 | 538 | lengthwise |

| 9.250x55.016._* | SOPL-S-250x55 | NBR (gr) | 8 | 770 | lengthwise |

| 9.300x55.019._* | SOPL-S-300x55 | NBR (gr) | 8 | 902 | lengthwise |

| 9.370x70.022._* | SOPL-S-370x70 | NBR (gr) | 10 | 1895 | lengthwise |

| 9.200x100.015._* | SOPL-S-200x100 | NBR (gr) | 8 | 595 | lengthwise |

| 9.280x100.017._* | SOPL-S-280x100 | NBR (gr) | 10 | 1,88 | lengthwise |

| 9.450x130.025._* | SOPL-S-450x130 | NBR (gr) | 6 | 2,66 | crosswise |

| 9.430x180.024._* | SOPL-S-430x180 | NBR (gr) | 6 | 3,72 | selective |

| 9.580x180.029._* | SOPL-S-580x180 | NBR (gr) | 10 | 3,5 | lengthwise |

| SOPL-A: NR material, orange, with aluminum carrier plate | |||||

| 9.100x55.020._* | SOPL-A-100x55 | NR (or) | 8 | 65 | lengthwise |

| 9.150x55.083._* | SOPL-A-150x55 | NR (or) | 8 | 114 | lengthwise |

| 9.200x55.020._* | SOPL-A-200x55 | NR (or) | 8 | 159 | lengthwise |

| 9.300x55.046._* | SOPL-A-300x55 | NR (or) | 8 | 300 | lengthwise |

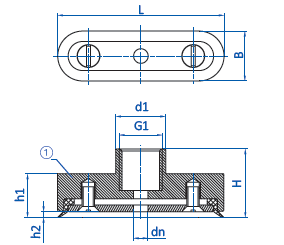

| Item no. | Drawing | L [mm] | B [mm] | l [mm] | l2 [mm] | b [mm] | Ø d1 [mm] | H [mm] | h3 [mm] |

| SOPL-S: NBR material, grey, with steel carrier plate | |||||||||

| 9.200x40.010._* | A | 195 | 36 | 176 | -- | 15 | -- | 19 | 6 |

| 9.110x40.009._* | A | 113 | 43 | 87 | -- | 17 | -- | 19 | 8,5 |

| 9.125x55.012._* | A | 126 | 56 | 103 | -- | 33 | -- | 19 | 6 |

| 9.150x55.013._* | A | 151 | 56 | 128 | -- | 33 | -- | 19 | 6 |

| 9.200x55.014._* | A | 200 | 55 | 178 | -- | 33 | -- | 19 | 6,3 |

| 9.250x55.016._* | A | 250 | 55 | 228 | -- | 33 | -- | 19 | 6 |

| 9.300x55.019._* | A | 300 | 55 | 227 | -- | 33 | -- | 19 | 6 |

| 9.370x70.022._* | A | 378 | 82 | 349 | -- | 53 | -- | 26 | 9 |

| 9.200x100.015._* | A | 190 | 90 | 161 | -- | 61 | -- | 22 | 8,5 |

| 9.280x100.017._* | A | 278 | 100 | 250 | -- | 72 | -- | 25 | 9 |

| 9.450x130.025._* | A | 449 | 131 | 420 | -- | 102 | -- | 20 | 6,5 |

| 9.430x180.024._* | A | 430 | 180 | 402 | -- | 158 | -- | 20 | 6 |

| 9.580x180.029._* | A | 579 | 179 | 570 | -- | 150 | -- | 25 | 9 |

| SOPL-A: NR material, orange, with aluminum carrier plate | |||||||||

| 9.100x55.020._* | B | 99 | 54 | 78 | 25 | 33 | 8 | 22,5 | 9 |

| 9.150x55.083._* | B | 150 | 55 | 128 | 40 | 33 | 8 | 22,5 | 9 |

| 9.200x55.020._* | B | 201 | 56 | 178 | 50 | 33 | 8 | 22,5 | 9 |

| 9.300x55.046._* | B | 300 | 55 | 278 | 100 | 33 | 8 | 22,5 | 9 |